Short Interval Control Training: Best practices to transition from paper-based systems to Digital.

Short Interval Control Training is key to transition a mine from traditional paper-based Short Interval Control (SIC) methods to digital systems in mining operations is a strategic move towards improving efficiency, safety, and decision-making. This process involves several key steps and training initiatives to ensure a smooth shift: Initial Assessment and Strategy Development The transition […]

GroundHog Install at Gold mine in Africa

Deployment Model for Site: Open Pit FMS Site Information GroundHog Deployed the OpsCenter for Dispatch, and the Fleet Management System app at a Gold Mine in North Africa Miners primarily spoke Arabic. So, GroundHog added Arabic Language support. Production Operations Management – Pre-GroundHog The site had operators capture information on paper to record their daily […]

GroundHog at Underground Zinc Mine

Deployment Model for Site: Short Interval Control & Fleet Management System with Supervisor App and Geology App Site Information GroundHog Deployed the OpsCenter for Dispatch, and the Fleet Management System app for one of the largest Underground Zinc mine in the US. In addition, GroundHog’s Customer Success team also assisted the mine with configuring the […]

GroundHog at Underground Copper Mine in USA

Deployment Model for Site: Mine Control (Dispatch) Mode Site Information Cementation USA deployed GroundHog’s flagship OpsCenter platform to use Short Interval Control and manage Dispatch operations to increase productivity and safety. Production Operations Management – Pre-GroundHog The site primarily used a combination of Excel and paper based processes (daily logs / PLOD sheets) to capture […]

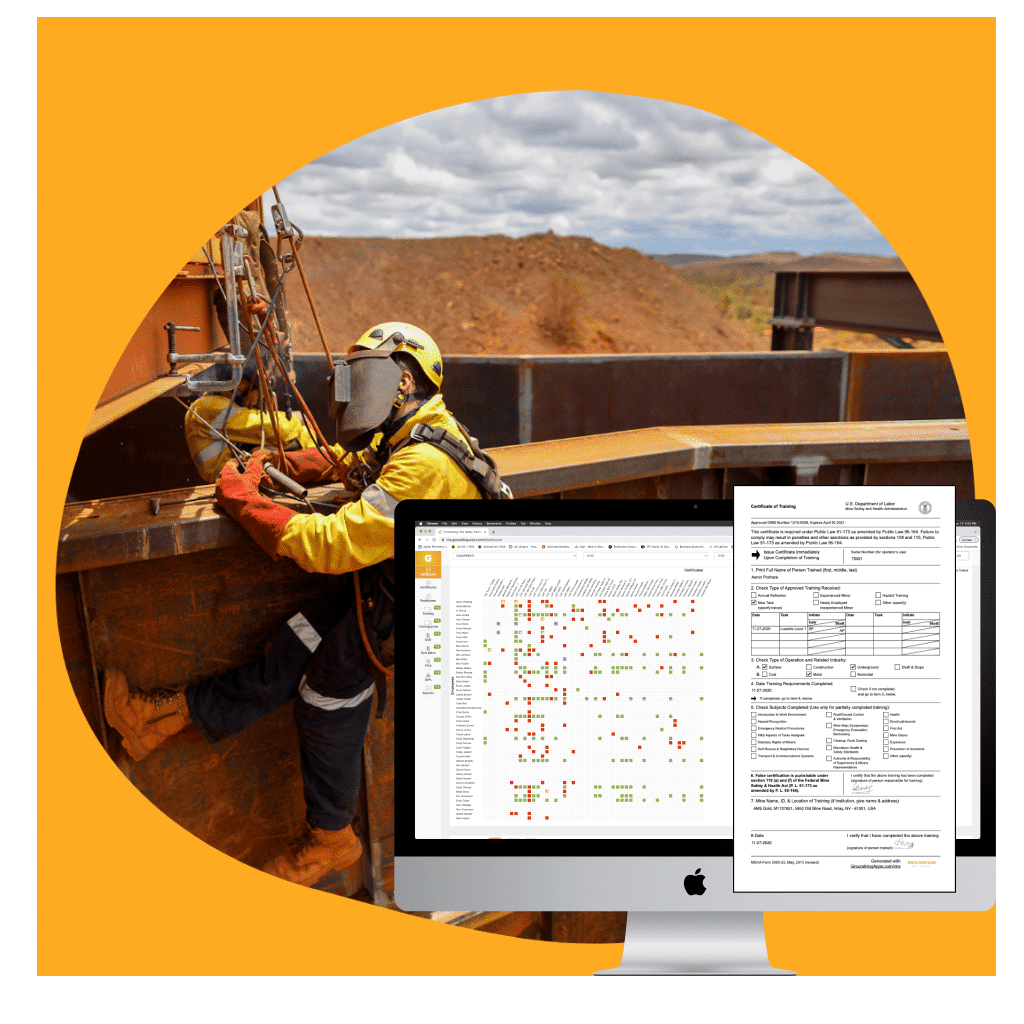

Building a Safer and More Productive Mining Workforce: The Power of Quality Safety Training Systems for Mines and Mining Contractors

Safety Training for a miner on how to operate a piece of equipment, or on the correct procedure for completing a task, not only leads to a safer operation, but to a more productive one as well. This is because safety and production go hand in hand. If you have employees who are taking shortcuts […]

Revolutionizing Mining Efficiency: Tilt Sensors for Dump Cycle Count Automation with Unparalleled Precision

#mining #innovation In a bold stride towards cutting-edge innovation in the mining industry, our team has achieved a groundbreaking feat: the successful installation of Tilt sensors on Haul Trucks for Dump Cycle Count Automation. This cutting-edge technology has enabled us to automate dump cycle counts while completely eliminating the need for any operator input. Paired […]

RTK or GNSS? What should a mine use?

RTK (Real-Time Kinematic) and GNSS (Global Navigation Satellite System) are both widely used technologies for utilizing GPS in mining operations. While they share the common goal of providing accurate positioning information, there are important differences between the two approaches. RTK: Real-Time Kinematic RTK is a precise positioning technique that utilizes a network of reference stations […]

RTK High Precision GPS: Because Mines need Grade Control and Compliance to Mine Design

RTK (Real-Time Kinematic) High Precision GPS technology comes is primarily used to achieve centimeter level precision in the mining industry – this is mostly required for when mining in heterogeneous strata where grade control is very important. It is also used to ensure that Dozers and Graders are building benches and ramps to the mine […]

How Mines use GPS

Starting in the early 90’s, Mines use GPS in a wide variety of ways. While technological advancements have played a crucial role in enhancing operational efficiency, safety, and productivity, GPS is one innovation that has revolutionized the way mines use location intelligence to unlock a myriad of benefits that have reshaped the way we mine. […]

5 ways to improve Asset Tracking in Underground Mines using RTLS

Asset tracking in underground mines is a critical part of your daily operations – it helps you get miners up-and-running faster so you can mine more tons every shift. Managing and locating valuable assets such as equipment, tools, and supplies in the challenging underground environment can be a daunting task. That’s where Real-Time Location Systems […]