Digital Mining and the Path to Green Mining

Green mining begins with operational discipline. In this eBook, we

Boost productivity with accurate weight tracking and actionable data insights.

The Power of Payload Monitoring

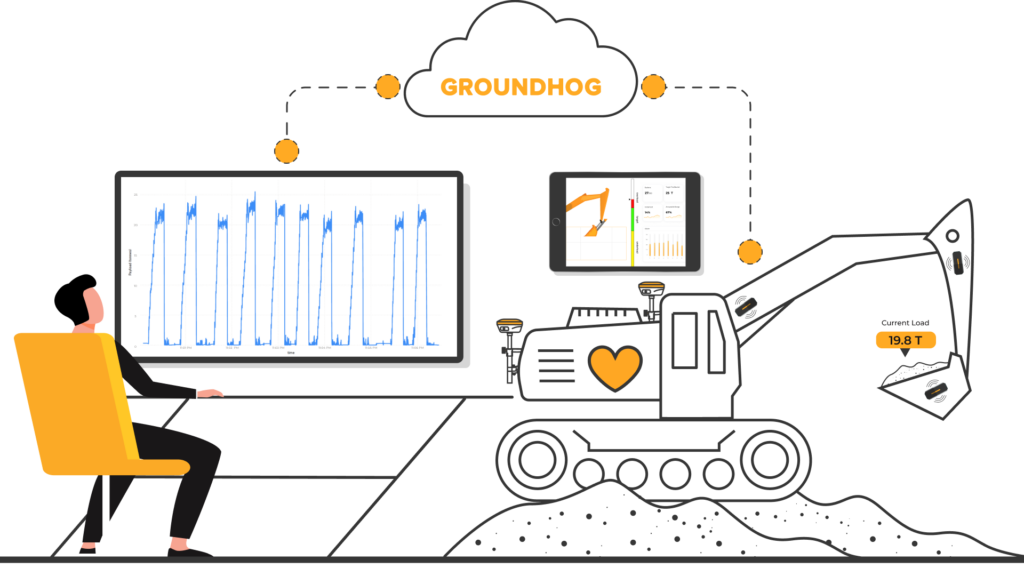

Real-time payload measurement ensures every load meets target weight by providing operators with immediate feedback. This technology eliminates the guesswork, optimizes load efficiency, and improves overall loading performance in mining operations.

Powerful Tools for Accurate Load Management

GroundHog seamlessly integrates with VEI onboard weighing solutions, providing unparalleled accuracy in production and load monitoring. This intuitive system enhances operational efficiency and offers cloud-based connectivity for real-time data access.

Boost Productivity and Reduce Maintenance Issues

Our system monitors operators in three key areas: Underloads, Overloads, and Acceptable Loads. Underloads decrease productivity, while overloads lead to maintenance issues and increased downtime. With real-time performance monitoring, we ensure loads remain within acceptable limits.

Unleash the power of payload monitoring

Read related blogs and access useful links

Green mining begins with operational discipline. In this eBook, we

Consolidates-operational-kpi-library-for-mining-performance … Read More

Long-term mine plans don’t fail because of one bad assumption.

Payload monitoring ensures that each load meets the target weight by providing real-time feedback to operators. This eliminates guesswork, optimizes load efficiency, and enhances overall loading performance in mining operations.

Real-time payload measurement tracks the weight of material loaded into trucks, ensuring accurate load distribution. Operators receive immediate feedback, which helps them avoid underloading (reducing productivity) and overloading (causing maintenance issues).

GroundHog seamlessly integrates with VEI onboard weighing systems, allowing for precise load monitoring. This integration enhances operational efficiency and provides cloud-based connectivity for real-time data access.

Our system monitors operator performance in three key areas:

By preventing overloads, the system protects equipment from excessive strain and damage, reducing maintenance costs and unplanned downtime. Keeping loads within acceptable limits extends the lifespan of mining trucks and shovels.

Operators and managers receive real-time data on:

This actionable data helps optimize decision-making, improve haulage efficiency, and increase overall site productivity.

Yes! GroundHog’s integration with VEI onboard weighing solutions makes it easy to implement on existing shovels, diggers, and haulage trucks without requiring extensive modifications.