Operational KPI Library For Mining Performance (Digital and Technology KPIs)

This technical guide brings together the Digital and Technology KPIs

Achieve operational excellence with precise payload tracking and actionable performance data.

The Key to Smarter Material Handling

With cutting-edge payload monitoring, every bucket load is optimized for maximum efficiency. Operators gain instant feedback on weight distribution, ensuring consistency and precision in every haul. This leads to improved cycle times, reduced fuel consumption, and optimized material flow.

Streamline Load Management

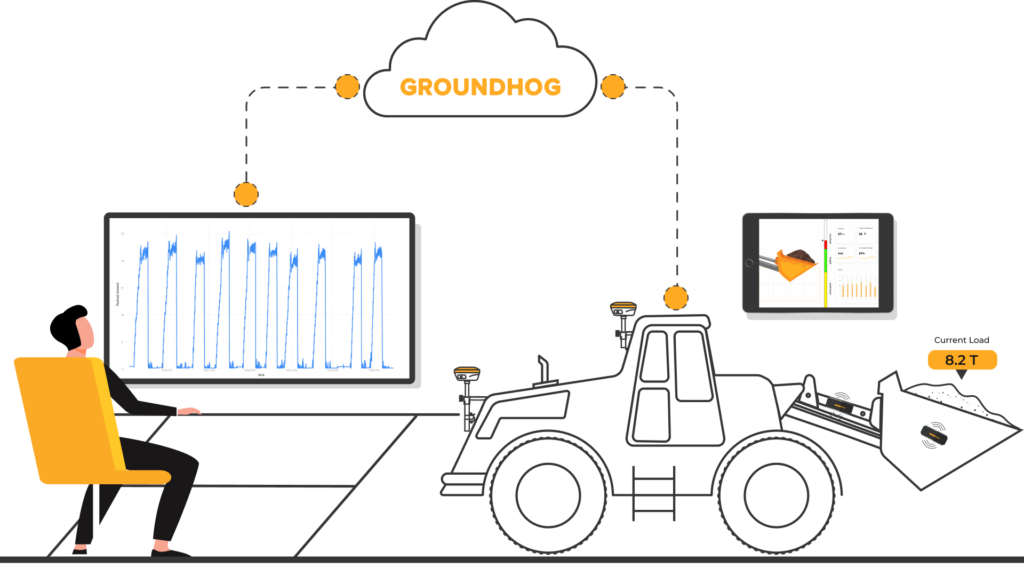

GroundHog integrates effortlessly with VEI onboard weighing systems to deliver highly accurate payload tracking. The system provides real-time access to critical data, empowering operators and managers to make informed decisions.

Reduce Downtime and Maximize Efficiency

Our system monitors key performance metrics such as underloading, overloading, and optimal loads. By providing real-time feedback, it maximizes operational efficiencies and reduces equipment stress, resulting in fewer maintenance issues and higher productivity.

The Key to Smarter Material Handling

Read related blogs and access useful links

This technical guide brings together the Digital and Technology KPIs

This technical guide brings together the Shared Operational KPIs that

This technical guide lays out the Underground Operational KPIs that

Payload monitoring is a technology that tracks the weight of each bucket load in real time, ensuring precise loading operations. It delivers actionable performance data so that every load is optimized for maximum efficiency, leading to smoother operations and improved cycle times.

Real-time load accuracy provides operators with instant feedback on weight distribution, eliminating guesswork and ensuring consistency. This results in:

GroundHog integrates seamlessly with VEI onboard weighing systems, providing:

The system closely monitors key metrics including:

Accurate payload tracking leads to:

By providing real-time feedback to prevent overloads, the system helps:

Both operators and management benefit:

By optimizing load distribution and preventing equipment overloading, the system reduces maintenance costs and improves fuel efficiency. The resulting streamlined operations translate into significant cost savings over time.