Operational KPI Library For Mining Performance (Digital and Technology KPIs)

This technical guide brings together the Digital and Technology KPIs

Optimize haulage efficiency with precise weight tracking and real-time performance insights.

The Power of Payload Monitoring

Real-time payload measurement ensures each haul truck carries the optimal load, preventing underloading and overloading. Operators receive immediate feedback to maintain accurate weight distribution, improving haulage efficiency and extending equipment lifespan

Enhancing Load Management with Precision Technology

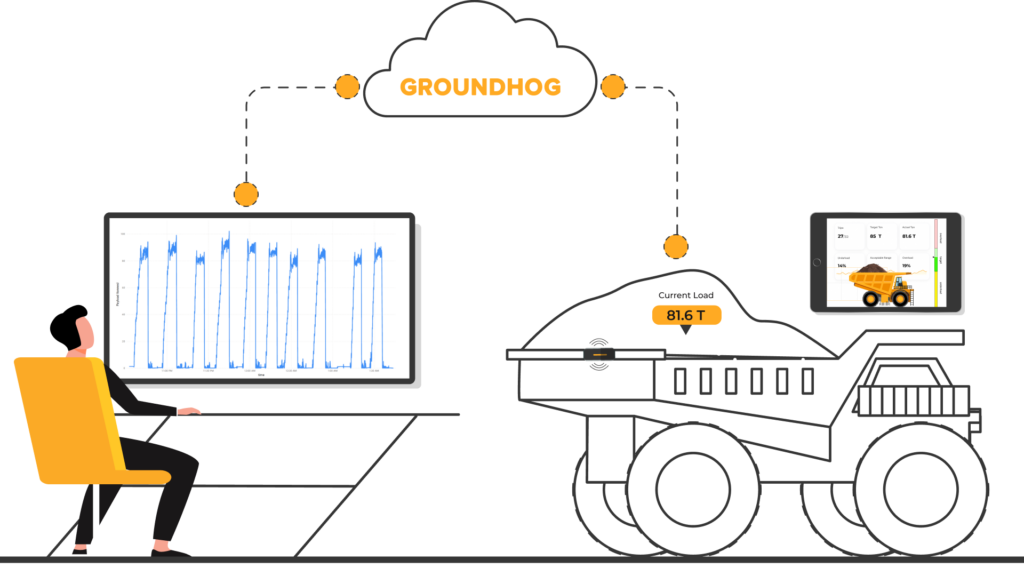

GroundHog integrates seamlessly with VEI onboard weighing solutions, delivering highly accurate payload tracking for haul trucks. With cloud-based connectivity, managers and operators gain real-time access to weight data, improving decision-making and fleet efficiency.

Boost Productivity and Reduce Maintenance Costs

Our system tracks key performance metrics, ensuring that each truck operates within ideal load limits. Underloaded trucks reduce productivity, while overloaded trucks increase wear and maintenance costs. With real-time monitoring, we help to maintain optimal loading conditions.

Optimize haulage efficiency with precise weight tracking and real-time performance insights.

Read related blogs and access useful links

This technical guide brings together the Digital and Technology KPIs

This technical guide brings together the Shared Operational KPIs that

This technical guide lays out the Underground Operational KPIs that

Haul truck payload monitoring is a technology that provides real-time weight tracking to ensure each truck carries the optimal load. It is essential for preventing both underloading and overloading, which can affect haulage efficiency and lead to equipment wear.

Real-time load measurement allows operators to monitor the weight of each load as it’s being applied. This immediate feedback helps in:

GroundHog integrates seamlessly with VEI onboard weighing systems to provide:

Accurate payload tracking enables:

The system continuously tracks key performance metrics to:

Real-time data empowers both operators and managers by providing:

By ensuring trucks are loaded optimally:

Both operators and fleet managers benefit: