Reshaping Mine Safety Training: Understanding MSHA-2025-0085

In the first half of 2025, MSHA issued over 43,000

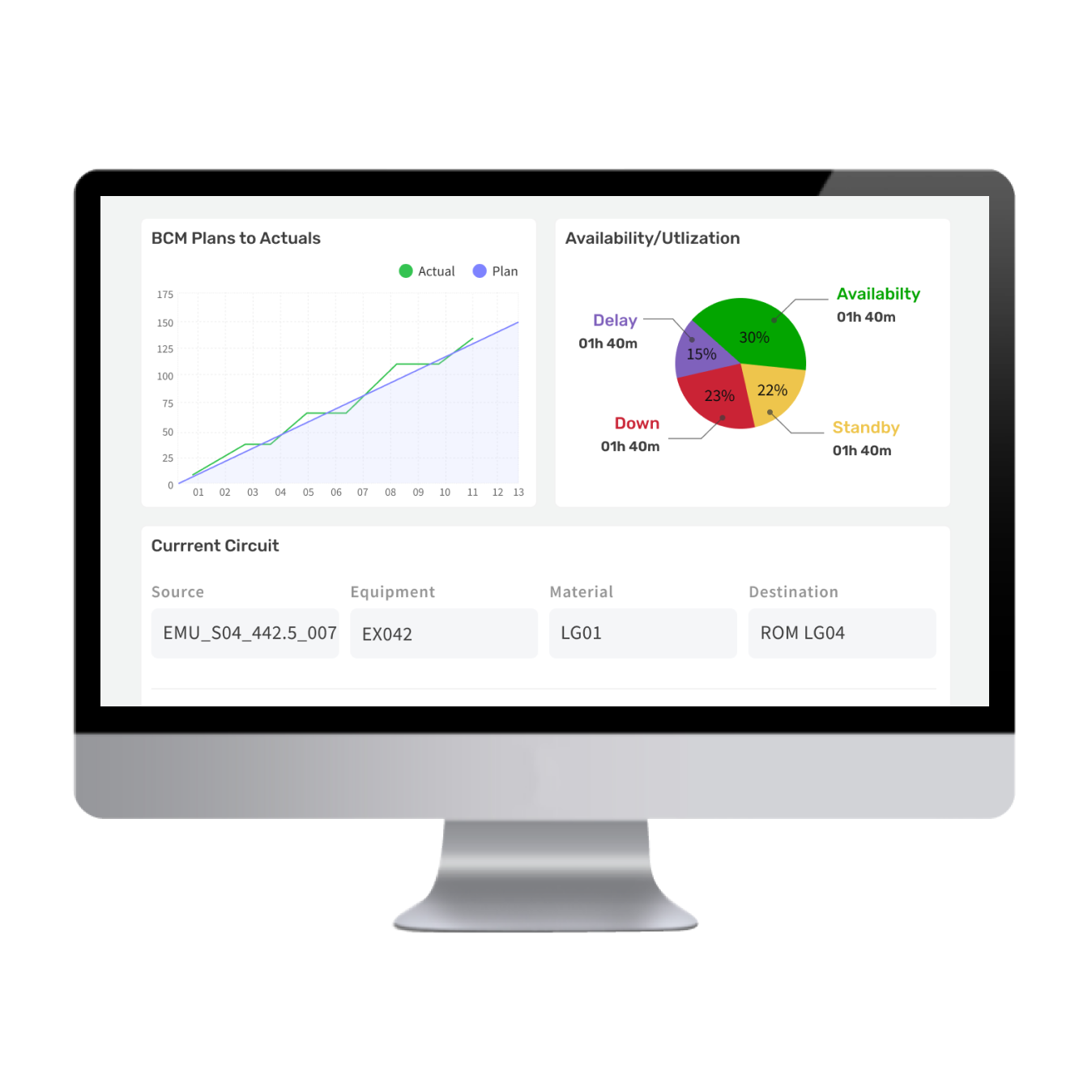

GroundHog FMS for AHS brings cutting-edge autonomous technology to your mining operations, enhancing safety, boosting efficiency, and reducing costs—all while driving sustainability. Achieve seamless, 24/7 haulage with precision tracking and optimized performance.

GroundHog FMS for AHS centralizes control and monitoring, removing risks tied to human drivers.

AHS trucks running on GroundHog FMS can operate continuously, enabling off-peak operations and maximizing asset utilization.

Boost Efficiency and Productivity with 24/7 Autonomous Operations

GroundHog FMS for AHS trucks intelligently plans and adjusts routes in real-time, reducing unnecessary travel and fuel consumption while maximizing haulage capacity.

Save on Operational Expenses with GroundHog FMS for AHS systems

By automating haulage, mining companies can reduce labor costs, particularly in regions with high labor expenses or difficult terrain. The consistent and repetitive patterns of AHS operations also reduce maintenance needs, extend component lifespan, and lower fuel consumption, all while contributing to a greener operation.

Flexible, Configurable, and OEM-Agnostic Solution

GroundHog’s Autonomous Haulage System (AHS) offers seamless integration across a variety of Original Equipment Manufacturers (OEMs), ensuring operational efficiency no matter the fleet composition. With its mixed fleet capability, AHS supports trucks and equipment from different manufacturers, enabling companies to manage their operations without compatibility concerns. The configurable software adapts to your specific fleet and operational needs, enhancing flexibility.

Customizable to fit unique operational requirements.

An autonomous solution designed to enhance safety, streamline operations, and improve efficiency

In the first half of 2025, MSHA issued over 43,000

Dans cet eBook, nous explorons comment l’industrie minière a évolué

Bu eKitapta, madencilik sektörünün dijitalleşme ve otomasyonun yükselişiyle nasıl dönüştüğünü,

AHS enhances safety by using obstacle detection and avoidance systems. Autonomous trucks are programmed to maintain safe speeds, distances, and lane positions. They operate without the risks of driver fatigue or distraction, and with advanced sensors, they can react quickly to sudden changes in road and traffic conditions. According to the World Economic Forum, automation and robotics in mining could prevent up to 10,000 injuries.

AHS optimizes routes using advanced mapping systems and allows for 24/7 transport without the need for breaks or shift changes. By using GNSS technology and geofencing, AHS tracks assets in real-time, ensuring precise movements and avoiding downtime. This constant operation increases productivity and improves cost and profit margins in mining operations.

AHS reduces labor costs, especially in areas with high labor expenses or challenging terrain. With its systematic operation, maintenance is minimized, extending the lifespan of components. Additionally, AHS helps reduce fuel consumption, greenhouse gas emissions, and overall energy usage, making it a cost-effective solution for mining companies.

AHS promotes sustainability by optimizing fuel consumption and operating at non-peak times, reducing traffic congestion and air pollution. Many AHS vehicles use hybrid or fully electric power. Additionally, IoT and AI technologies are used for predictive maintenance, which reduces breakdowns and enhances the overall sustainability of the mining operation.

Yes, AHS is equipped with advanced sensors and control systems that allow it to adapt quickly to changes in road or weather conditions. This ensures that the trucks can continue operating safely, even in unpredictable environments, minimizing downtime and operational disruptions.

AHS uses GNSS technology to track assets with pinpoint accuracy. It also incorporates geofencing to control the movement of vehicles within designated areas, ensuring that all equipment operates in the right place at the right time, further increasing operational efficiency.

While there is an initial investment required to implement AHS, the long-term cost savings—such as reduced labor, lower fuel costs, and extended equipment lifespan—make it a highly cost-effective solution for mining operations in the long run. Additionally, the increased productivity and sustainability benefits offer a strong return on investment