Reshaping Mine Safety Training: Understanding MSHA-2025-0085

In the first half of 2025, MSHA issued over 43,000

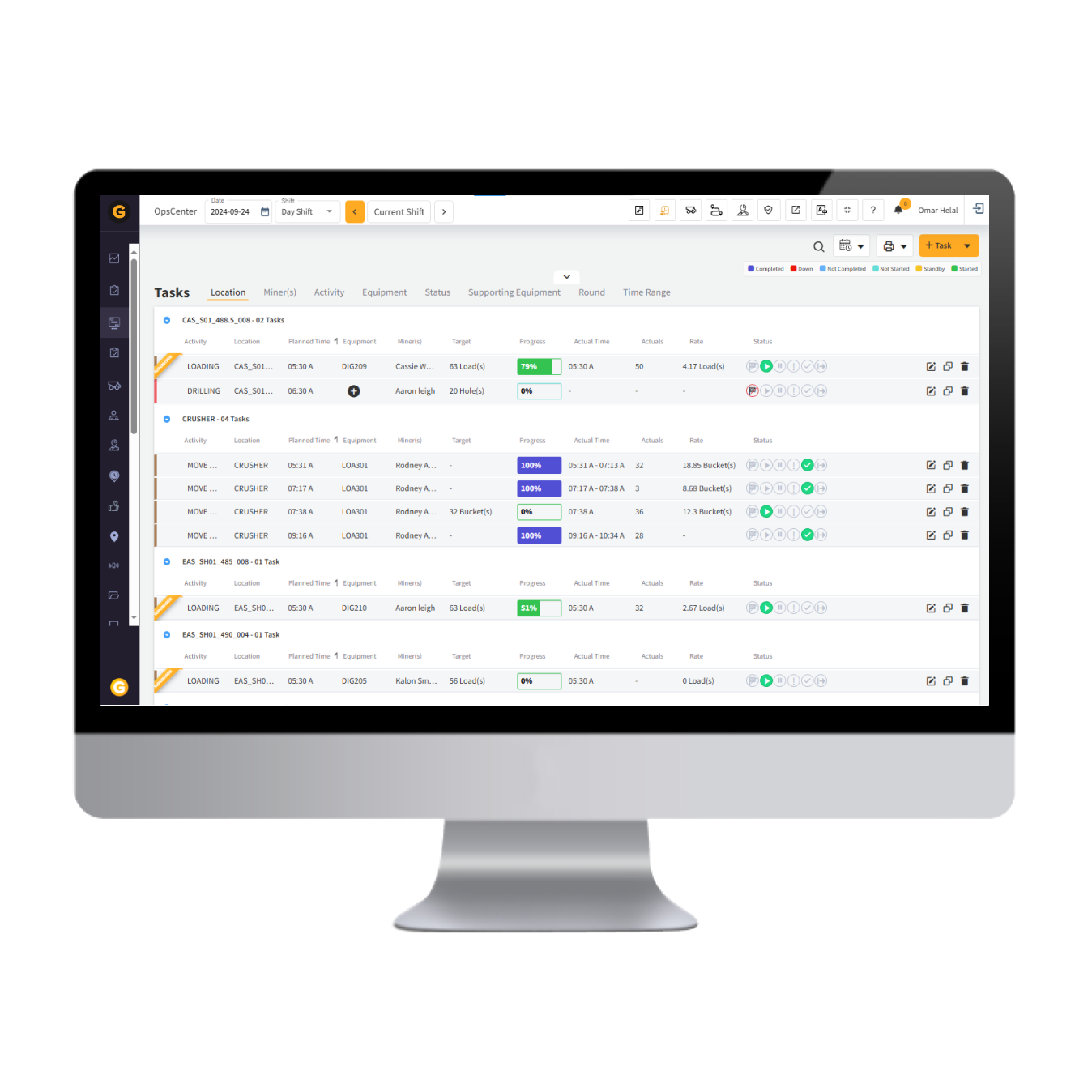

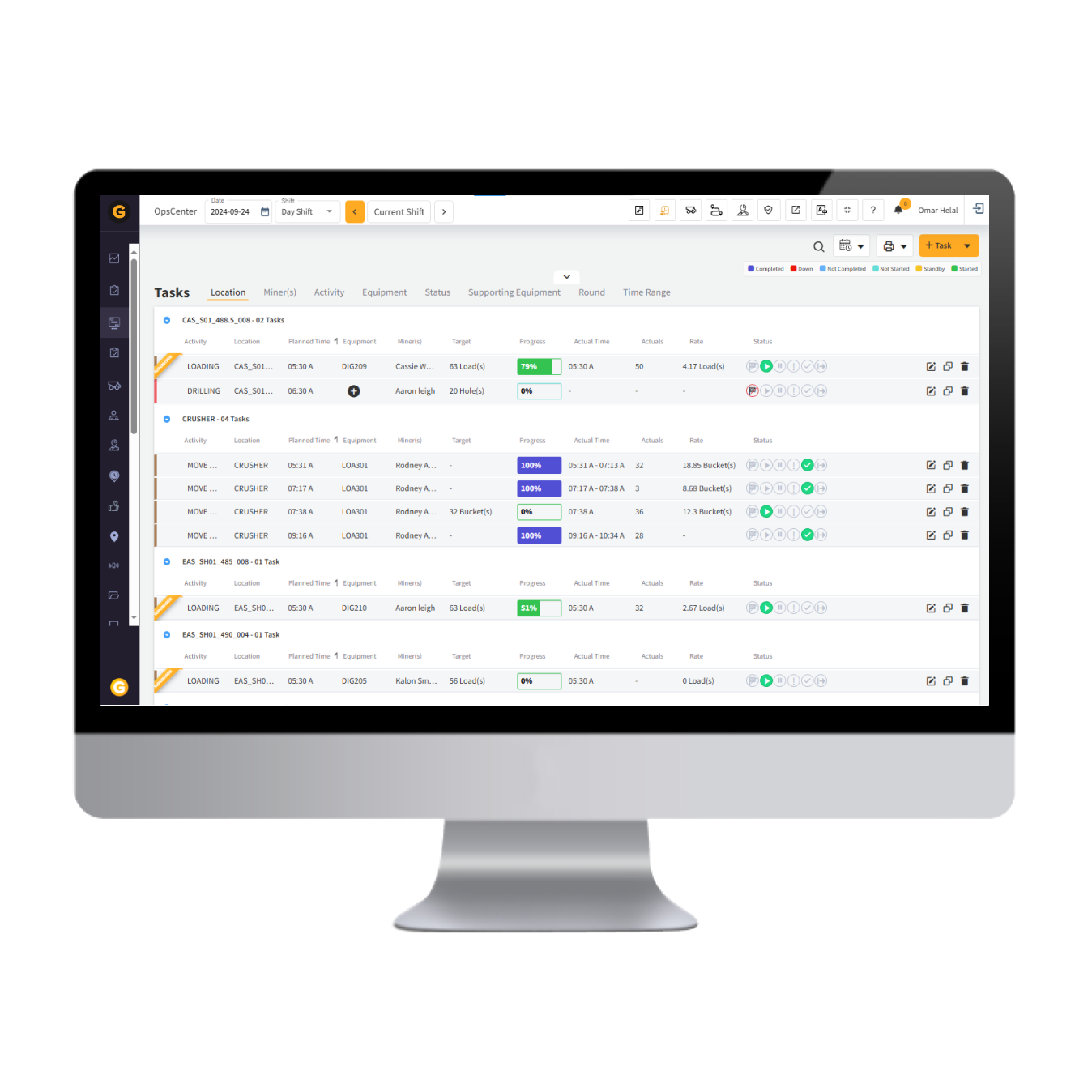

GroundHog SIC transforms your work planning with faster adjustments and quicker shift starts,

resulting in higher productivity and more efficient operations.

Speed Up Shift Starts and Get Operators to Equipment Faster with GroundHog SIC

In traditional open-pit mining, shift allocation is done manually, which slow down operations. But with GroundHog Short Interval Control, it’s all automated, making shift allocation as easy as a single click.

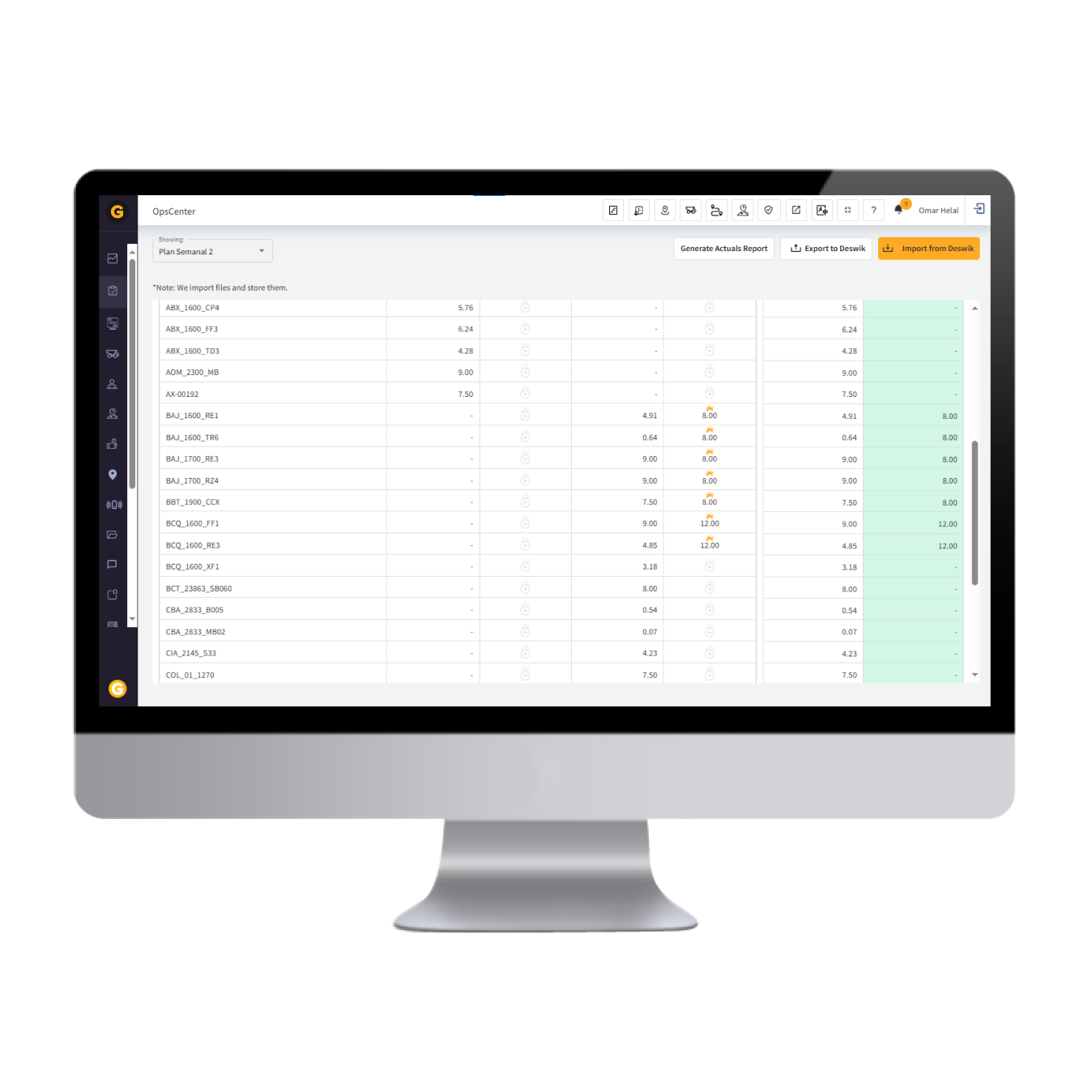

Improve Compliance with Your Life of Mine Plans

GroundHog Short Interval Control creates and executes plans that align with your mine’s overall plan. It monitors and controls deviations to ensure timely and budget-compliant goals.

Drive productivity with streamlined communication and effective task delegation.

Our Short Interval Control enhances task distribution and communication, ensuring effective coordination and clear understanding within the team.

Drive continuous improvement through timely and efficient reviews.

GroundHog Short Interval Control improves in-shift management in open-pit mining through real-time task tracking, consumable monitoring, and downtime management, leading to enhanced efficiency. GroundHog Mine Control Services assist in monitoring these activities throughout the shift.

Discover How GroundHog Short Interval Control makes Shift Planning Easy!

Read related blogs and access useful links

In the first half of 2025, MSHA issued over 43,000

Dans cet eBook, nous explorons comment l’industrie minière a évolué

Bu eKitapta, madencilik sektörünün dijitalleşme ve otomasyonun yükselişiyle nasıl dönüştüğünü,

GroundHog SIC is a state-of-the-art Mining Short Interval Control system designed to maximize sustainable mining intensity in both underground and open pit operations. It features user-centered design, controls production, schedules, tracks workforce, and provides insights to enhance process efficiency.

GroundHog SIC seamlessly integrates with other GroundHog products, including Fleet Management System, Real-Time Location Tracking, Telematics, IoT, and more. It also supports Open APIs for easy integration with third-party software like SAP, mine planning tools, HRMS, and maintenance management systems.

GroundHog SIC uses a Greedy Algorithm-based autoscheduler to automatically allocate equipment and personnel, optimizing utilization. Supervisors can also manually assign tasks using a drag-and-drop interface. Completed tasks are distributed to monitors, tablets, and smartphones, ensuring everyone knows their tasks and equipment locations.

Crew supervisors use GroundHog’s Line-up app to streamline line-up meetings, ensuring that all team members are informed and prepared for their tasks.

OpsCenter personnel or Dispatch monitor real-time production and adjust shift plans based on actuals reported through the SIC app or Fleet Management System. In the absence of an FMS, radio communications are used to update actuals.

Shift supervisors assess the reasons for downs or delays, evaluate their impact, and reassign equipment or operators as needed. Maintenance is notified with details and impact to quickly address equipment issues and minimize production disruptions.

Shift logs include KPIs such as advance rates, tonnes mined, material routing, and consumables. They also detail individual tasks, completion rates, variances, production losses, hazards, equipment exams, and workplace exams. These reports assist production planners and supervisors in making informed decisions for future shifts.