Reshaping Mine Safety Training: Understanding MSHA-2025-0085

In the first half of 2025, MSHA issued over 43,000

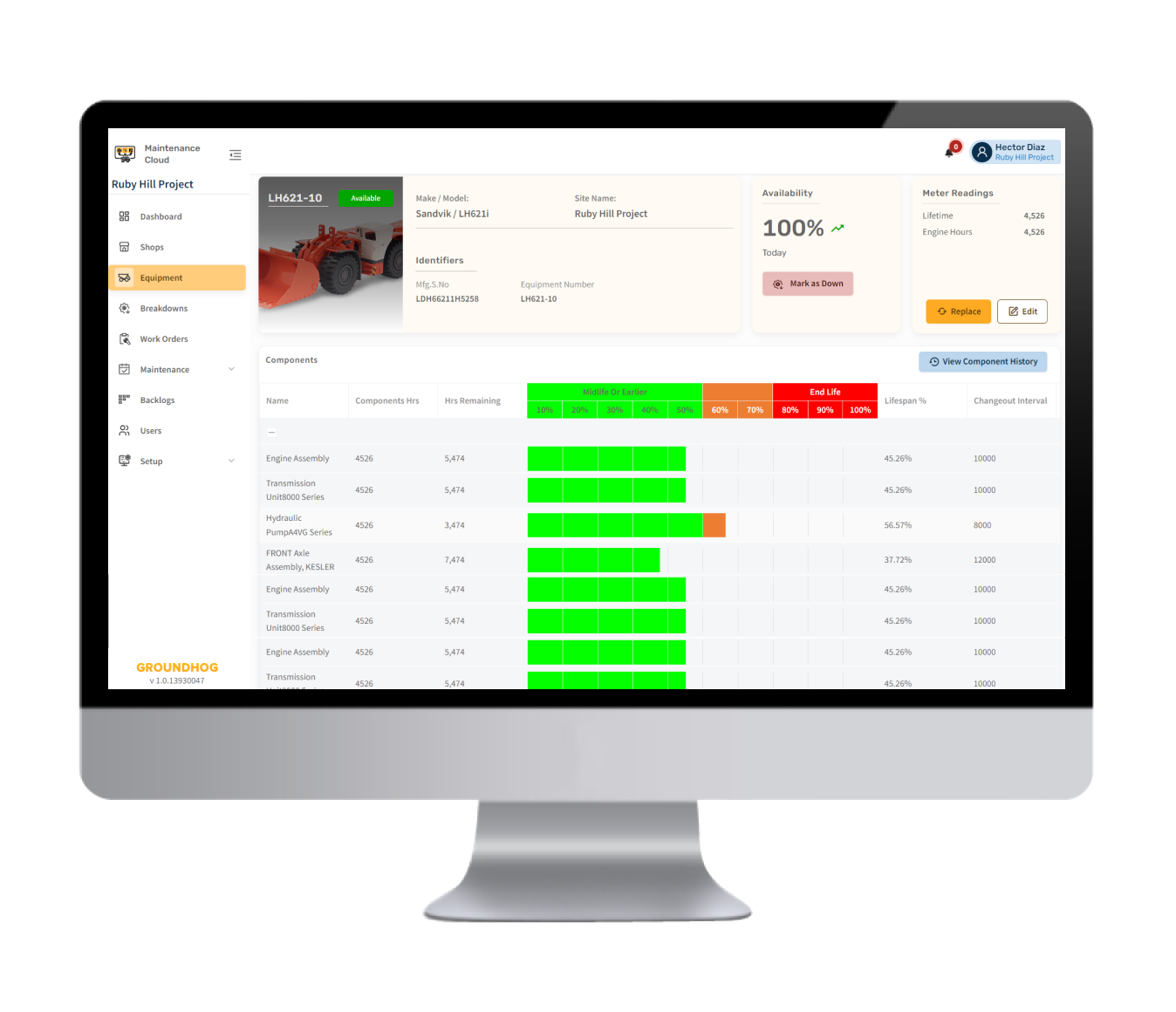

Record Repair Actions and Analyze Data to Identify Trends and Optimize Future Maintenance.

Centralize Data with GroundHog CMMS and Track Real-time

GroundHog Maintenance Cloud centralizes and tracks inventory, automates reordering, analyzes usage, and integrates with maintenance orders for efficient management.

Gain Complete Control Over your Inventory – Right Equipment at The Right Place.

Gain insights from historical data for better stocking and planning, and integrate component management with maintenance work orders for efficient repairs and reduced downtime.

Discover How GroundHog Maintenance Integrates Seamlessly Across All Channel

Read Related Blogs and Access Useful Links

In the first half of 2025, MSHA issued over 43,000

In the first half of 2025, MSHA issued over 43,000

In mining, nothing moves without the dispatcher — and a

Tracking and managing parts and equipment to ensure availability, optimize stock levels, and support maintenance activities.

It minimizes downtime, reduces costs, improves efficiency, and supports maintenance planning.

It tracks stock levels, automates reordering, manages suppliers, records usage, and maintains detailed records.

Real-time tracking, automated alerts, integration capabilities, and reporting tools.

By providing accurate data, efficient reordering, enhanced reporting, and integrated solutions.

It helps predict maintenance needs and manage inventory for critical parts, reducing unexpected shortages.

Through regular audits, standardized procedures, staff training, and system integration.

Stockouts, overstocking, data accuracy issues, and supplier management problems.