Learn how to efficiently extracting telemetry data from heavy equipment using GroundHog FMS. This guide provides essential steps and insights for leveraging real-time data to enhance operational efficiency, reduce downtime, and drive smarter decision-making in mining operations. … Read More

Masonry Blog

Short Interval Control with GroundHog

The eBook, Short Interval Control in Mining, explores how implementing Short Interval Control (SIC) in mining operations, specifically through GroundHog’s digital tools, can enhance productivity and operational efficiency. SIC is a structured approach to managing tasks in shorter intervals, typically

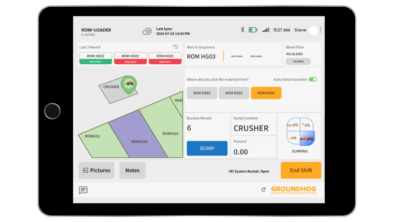

Ore Blending and Grade Control at ROM Stockpile

Harnessing High-Precision GPS for Enhanced Ore Quality Control in Open-Pit Mines … Read More

Essential Guide to MSHA-Compliant Mobile Equipment Training for Safe Mining Operations

Mobile Equipment Training is vital for mining safety and MSHA compliance. Proper training ensures operators are skilled, compliant, and ready for the demands of a mining environment … Read More

Optimizing Ore Control and Reducing Dilution with GroundHog’s Precision Solutions

Harnessing High-Precision GPS for Enhanced Ore Quality Control in Open-Pit Mines … Read More

Harnessing High-Precision GPS for Enhanced Ore Quality Control in Open-Pit Mines

Harnessing High-Precision GPS for Enhanced Ore Quality Control in Open-Pit Mines … Read More

Unlocking Efficiency: Ore Dilution and Quality Control in Open-Pit Mines

We’ll talk about how we can control ore dilution using High-Precision GPS and Geology & Ore Solutions to make mining more efficient, safer, and more sustainable. In this first part, we’ll give a general overview of the types of dilutions in open-pit mines and how dilution can reduce the value of the mine. … Read More

Long hole stoping with SIC

Over the last few years, many underground mines have started using the Longhole Open Stoping mining method to extract ore more efficiently — especially in metal mines. One metric commonly used to track the efficiency of these mines is the

A Guide to Harnessing CAT Telemetry Data

Understanding Telemetry and Diagnostics Most Original Equipment Manufacturers (OEMs) comply with the J1939 standard for heavy equipment diagnostics, particularly for diesel engines. Light vehicles using petrol engines adhere to the OBD-II standard. Companies like Caterpillar, Komatsu, and Epiroc utilize the

How to read Telemetry Data from Normet Equipment?

GroundHog’s mission is to digitize every mine worldwide and share learned insights to accelerate industry innovation. This eBook focuses on how to read telemetry data from Normet equipment, particularly their diesel engines, to enhance maintenance and operational efficiency. Types of