In the first half of 2025, MSHA issued over 43,000 citations — and nearly 20% were classified as “Significant & Substantial.” But here’s the kicker: the most common MSHA violations weren’t obscure or technical. They were for basic safety failures like poor housekeeping, missing machine guards, and unsafe access. This blog breaks down the top MSHA violations in metal/nonmetal mines and explains how getting the fundamentals right can drastically reduce citations and keep your team safe. … Read More

Standard Blog

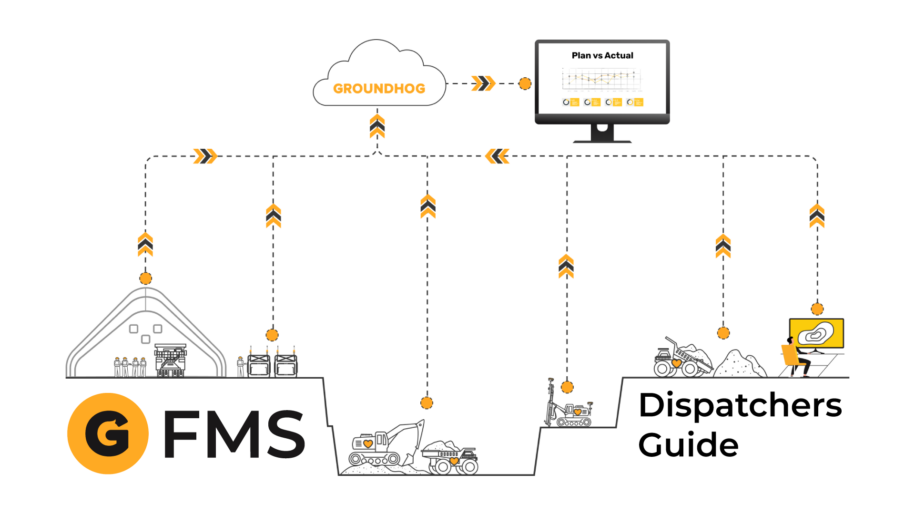

How Smart Dispatch Management Transforms Mine Productivity: FMS Tools You Need

In mining, nothing moves without the dispatcher — and a Fleet Management System like GroundHog puts real-time control at their fingertips. From assigning haul trucks to tracking tonnes moved and managing shift handovers, GroundHog gives dispatchers the tools to optimize performance every minute of the shift. With live dashboards, automated reporting, and fewer radio calls, dispatchers work smarter and faster. Whether you’re new to the role or upgrading from paper-based systems, mastering GroundHog is key to driving mining productivity. … Read More

GroundHog Cloud Maintenance Solution

Keeping mining equipment running efficiently is critical to hitting production targets. In this eBook, we cover how the GroundHog Cloud Maintenance Solution helps mines reduce downtime, extend equipment life, and shift from reactive to proactive maintenance. Designed for both underground

5 Essential Ways Long-Term Mine Scheduling Drives Profitable Operations

Long-term mine scheduling lays the foundation for achieving strategic business objectives by guiding the extraction sequence over the entire life of the mine. Unlike short-term scheduling, which focuses on daily operations, long-term planning demands a deep understanding of orebody characteristics, equipment capacity, and market dynamics. GroundHog empowers mine planners with real-time data integration, predictive analytics, and scenario simulation tools to develop adaptable, cost-effective, and sustainable life-of-mine schedules. By aligning operational execution with strategic goals, GroundHog helps mining operations maximize profitability and long-term resource recovery. … Read More

The Next Big Mining Boom Is Digital – Powered by AI

The richest vein in mining today isn’t a mineral – it’s data. AI is turning that data into actionable insights, and the industry is at a critical inflection point. … Read More

A Guide to MSHA, the Federal Mine Safety Act, and the Program Policy Manual

The Federal Mine Safety and Health Act of 1977 revolutionized mine safety in the United States by creating MSHA and centralizing regulations under Title 30 of the CFR. This article explores the history of mining regulation, the challenges of staying compliant, and how tools like MSHA’s Program Policy Manual help mine operators and safety professionals navigate complex safety standards to protect miners and ensure safe operations. … Read More

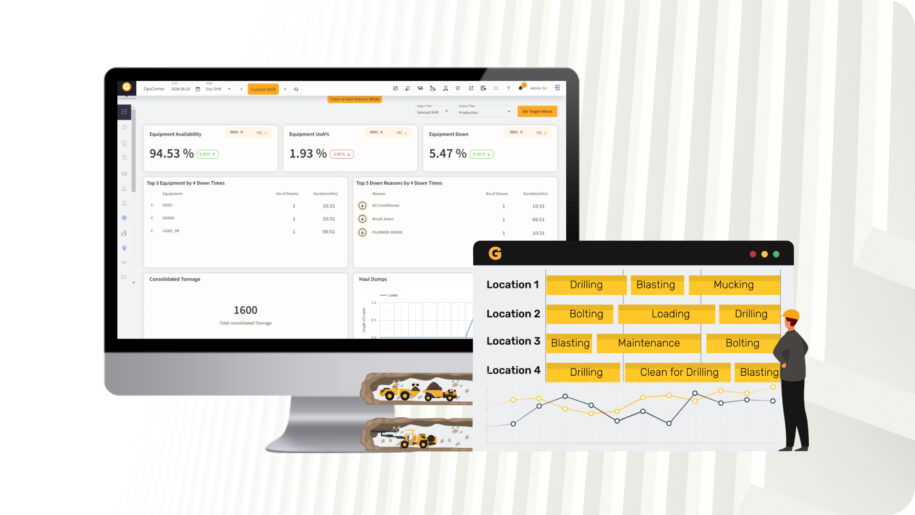

Understanding Short-Term Scheduling in Mine Operations with GroundHog

Mining success depends on the seamless integration of long-term strategies and short-term execution. While long-term planning lays the foundation for the overall direction of a mine, short-term scheduling ensures that daily activities contribute to achieving those strategic goals. In this blog, we explore how to bridge the gap between these two essential components of mine operations. … Read More

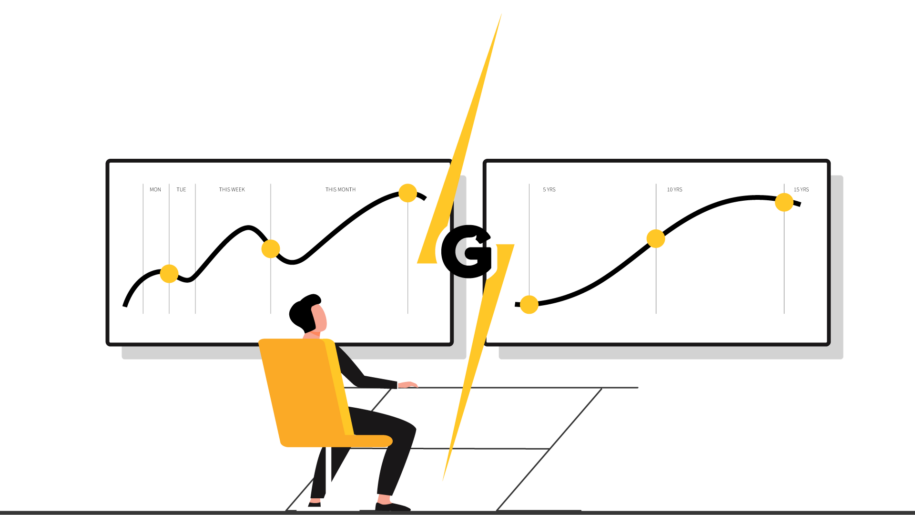

Long-Term vs. Short-Term Planning: Bridging the Gap

Mining success depends on the seamless integration of long-term strategies and short-term execution. While long-term planning lays the foundation for the overall direction of a mine, short-term scheduling ensures that daily activities contribute to achieving those strategic goals. In this blog, we explore how to bridge the gap between these two essential components of mine operations. … Read More

Short-term Planning in Longhole Stoping Operations

Short-term Planning in Longhole Stoping Operations … Read More

2025: A Year to Prioritize Workplace Safety

Workplace safety in mining has come a long way, but 2025 is off to a troubling start. With six fatalities recorded in just over a month, we are seeing a recurrence of preventable accidents tied to known hazards. This article explores the history of mining fatalities, the regulations that have shaped modern safety practices, and why we must act now to stop this dangerous trend. The risks are understood, and the solutions exist—it’s time to ensure every miner goes home safe. … Read More