Digital Mining and the Path to Green Mining

Green mining begins with operational discipline. In this eBook, we

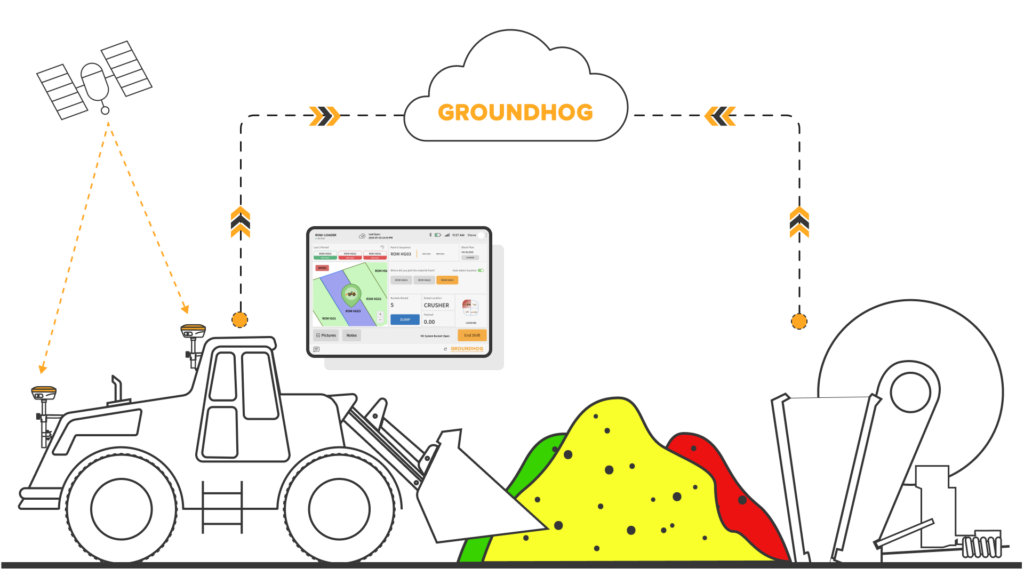

The GroundHog ROM Loader software is designed to revolutionize how raw materials are managed, from the ROM pad to the crusher, ensuring that every load is accurately tracked, and the blend plan is meticulously followed.

Real-Time Blend Sequence Management: Ensuring Optimal Material Mix

Each morning, operators receive a blend plan that outlines the exact sequence for material loading. The wheel loader can go to the exact location of the ore blend and pick in the exact sequence as per the blend plan.

Streamline Your Mining Operations: Improve Throughput with GroundHog’s ROM Loader

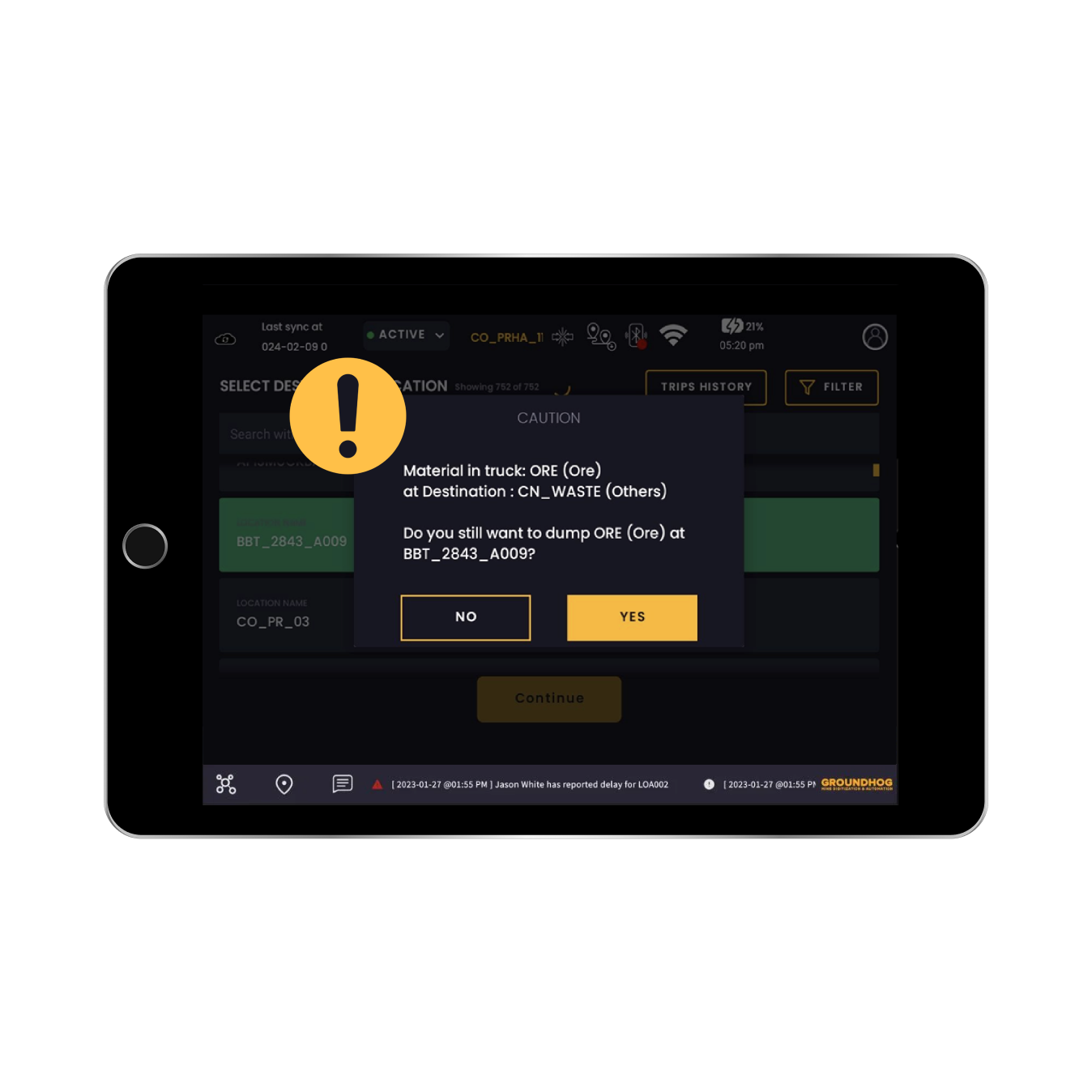

If an operator deviates from the blend plan, the software instantly detects the error and issues an alert, helping the operator to return to the correct sequence.

Take Control of Your Raw Material Handling: Enhance Yield with GroundHog ROM Loader

Traditional methods struggle with precise tracking of material loaded into the crusher. The ROM Loader Software accurately measures and logs each bucket’s payload.

Revolutionize Stockpile Management and Blend Accuracy with GroundHog ROM Loader

After material is transferred from the stockpile to the crusher, it’s essential to keep stockpile records up-to-date. The software automates this by deducting the material in real time.

Unlock the Full Potential of Your ROM Pad with GroundHog’s Cutting-Edge Technology

Traditionally, operators use paper-based methods to track the loading sequence. The ROM Loader Software digitalizes this process, automatically tracking the sequence.

Maximize Time Utilization: Track Every Moment for Peak Productivity

The ROM Loader Software includes a Time Utilization Model (TUM) that monitors operational metrics such as vehicle breakdowns, blend plan changes, and non-productive time.

Discover How GroundHog ROM Loader automates your blend management

Read related blogs and access useful links

Green mining begins with operational discipline. In this eBook, we

Consolidates-operational-kpi-library-for-mining-performance … Read More

Long-term mine plans don’t fail because of one bad assumption.

A ROM pad is a storage area where raw materials are grouped together. It typically includes low, medium, and high-grade materials stored in different blocks within the ROM pad.

The software is designed for use with wheel loaders, a type of vehicle used in mining operations.

At the start of each shift, the operator receives a blend plan. This plan outlines the proper sequence of raw materials to be prepared, such as which bucket to pick from specific blocks. For example, the plan may require one bucket from HG01 followed by two buckets from LG03. The sequence is formulated based on the feed quality, and the plan is adjusted accordingly.

Yes, the software tracks whether the operator is following the blend sequence. If the operator picks material from the wrong spot, an alert is sent, notifying them that they are not following the blend plan.

The software tracks the amount of material being loaded from the bucket into the crusher. This allows for accurate tracking of the payload entering the crusher, which is typically difficult to monitor manually.

Yes, the software keeps track of stockpile balances. When material is moved from the stockpile to the crusher, the software automatically deducts it from the stockpile. This ensures accurate and efficient stockpile management.

Each time the wheel loader picks up material from a block, the software helps the operator track if they’ve picked from the correct block according to the blend plan. It also guides them on which block to pick from next.

The Time Utilization Model (TAM) tracks various details such as vehicle breakdowns, changes in the blend plan, lunch breaks, and other factors. This tracking helps monitor how long the operator has been working and optimizes time management.