Digital Mining and the Path to Green Mining

Green mining begins with operational discipline. In this eBook, we

Real-Time Monitoring, AI-Driven Analytics, and Advanced Theft Prevention for Optimized Fuel Efficiency

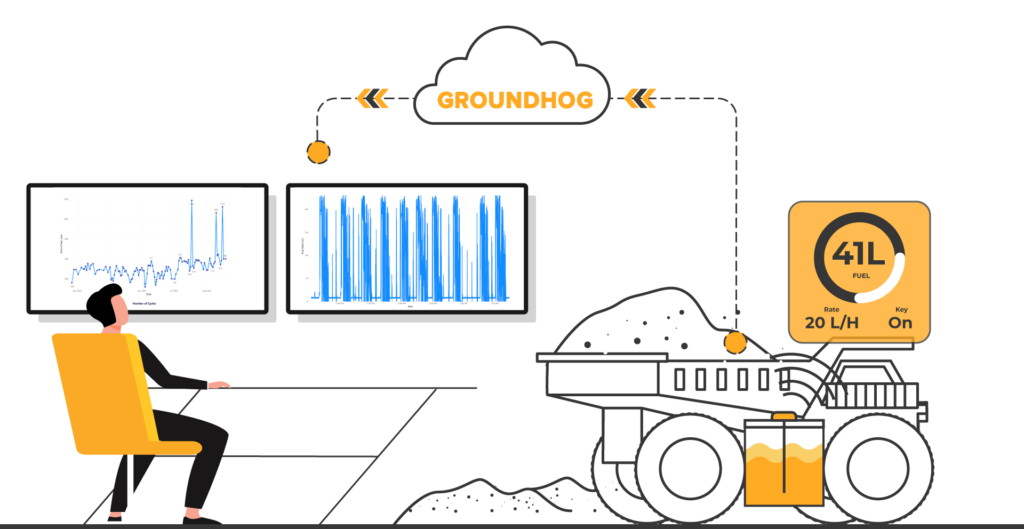

Real-Time Fuel Monitoring Across Your Fleet

GroundHog’s fuel sensors continuously collect and transmit data on fuel levels, key on/off status, idling, consumption rates, and operator ID via an on-board tablet with an inbuilt GPS chip. The system works in both online and offline modes, sending data to the GroundHog cloud for real-time visualization of fuel levels and consumption patterns across all Heavy Equipment and Light Vehicles.

AI-Driven Insights for Fuel Efficiency

GroundHog’s AI-powered Fuel Analytics helps mine planners detect fuel consumption hotspots, particularly during loaded haulage. When combined with GroundHog’s Fleet Management System and Load-cell Tonnage Sensors, it provides actionable insights that drive ramp design improvements, boost fuel efficiency, and protect transmission subsystem health.

Prevent Fuel Theft with AI-Powered Alerts

GroundHog’s integrated Fuel and Fleet Management System sends instant alerts when it detects suspicious fuel drops. Using AI, the system correlates fuel level changes with ignition state and equipment speed, giving supervisors the data they need to investigate potential theft.

Upgrade Legacy Equipment with Advanced Sensors

GroundHog offers solutions for older equipment lacking built-in fuel sensors. Using ruggedized capacitive or ultrasonic sensors, you can monitor fuel levels even on legacy vehicles. Capacitive sensors require tank drilling, while ultrasonic sensors do not, offering flexibility based on your needs. Both options are dustproof, waterproof (IP68/IP69k), and explosion-proof (Exd II CT5).

Accurate Fuel Monitoring for Loaded and Empty Haul Trucks

GroundHog automatically calculates fuel consumption rates for loaded and empty haul trucks, using retrofit sensors where needed. This ensures precise fuel data even on equipment without built-in fuel monitoring, enabling better decision-making for fleet management.

From real-time monitoring to theft prevention, we’ve got your mining operations covered.

Read related blogs and access useful links

Green mining begins with operational discipline. In this eBook, we

Consolidates-operational-kpi-library-for-mining-performance … Read More

Long-term mine plans don’t fail because of one bad assumption.

GroundHog’s fuel sensors continuously track fuel levels, key on/off status, idling, and consumption rates. The data is transmitted in real-time via GPS, even in offline modes, and is sent to the GroundHog cloud for easy visualization and analysis across your entire fleet.

GroundHog’s AI-driven Fuel Analytics identifies fuel consumption hotspots, particularly for loaded haulage. It helps mine planners optimize routes, improve ramp designs, and protect transmission subsystems, resulting in increased fuel efficiency.

GroundHog’s system sends fuel theft alerts by analyzing drops in fuel levels in correlation with ignition state and equipment speed. This AI-powered system provides supervisors with real-time notifications, including driver and location information, for immediate investigation.

Yes, older heavy equipment can be retrofitted with capacitive or ultrasonic sensors. Capacitive sensors require drilling into the fuel tank, while ultrasonic sensors do not. Both sensor types are ruggedized, dustproof, waterproof (IP68/IP69k), and explosion-proof (Exd II CT5).

GroundHog’s system automatically calculates fuel consumption rates for both loaded and empty haul trucks. It uses data from the built-in or retrofit sensors to provide accurate, real-time fuel monitoring and optimize fleet performance.