Digital Mining and the Path to Green Mining

Green mining begins with operational discipline. In this eBook, we

Transform your mine’s production by identifying bottlenecks, optimizing cycles, and engineering sustained operational excellence.

GroundHog Performance Engineering helps your mine find the real constraint — and fix it with precision.

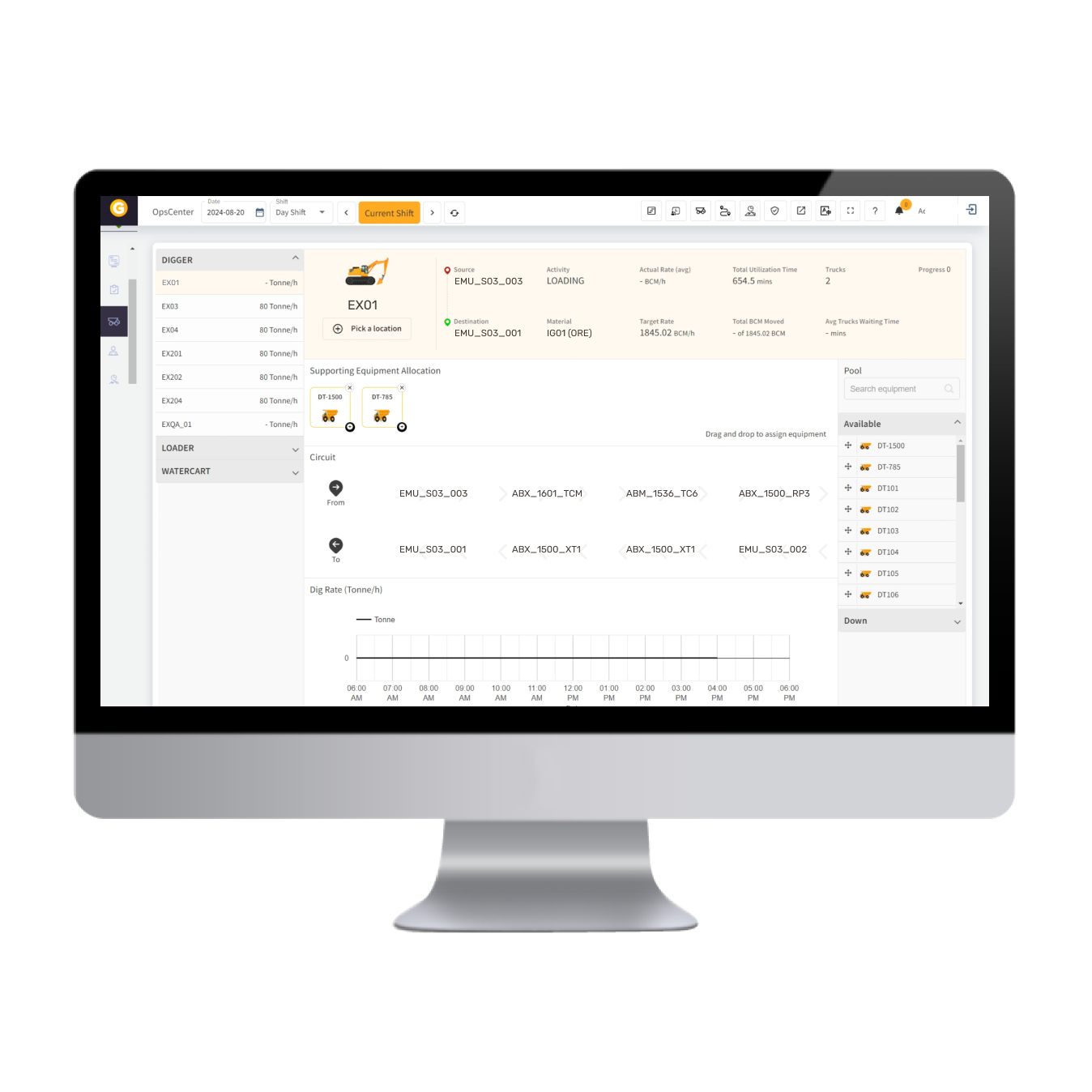

Most mines collect data. Few convert it into actionable constraints. GroundHog’s Performance Engineering framework maps your full production value chain to isolate the single bottleneck limiting throughput.

Improve TKPH and lower cost per tonne — without adding more trucks.

Using actual FMS data, haul profiles, and equipment telemetry, we build an end-to-end fleet model that shows what your mine should be producing — and why it isn’t.

Reduce pass variance, improve payload consistency, and enhance loading rhythm

We evaluate digging patterns, bucket dynamics, operator timing, and equipment interactions to engineer high-performing loading systems.

Real uplift — captured, measured, and sustained

Each improvement sprint produces measurable gains in throughput, availability, or cycle efficiency.

Equip your team to run Performance Engineering independently

We deliver the tools, templates, and workflows needed for ongoing improvement

Performance Engineering is built for mines that want more than data — they want engineered outcomes

Read related blogs and access useful links

Green mining begins with operational discipline. In this eBook, we

Consolidates-operational-kpi-library-for-mining-performance … Read More

Long-term mine plans don’t fail because of one bad assumption.

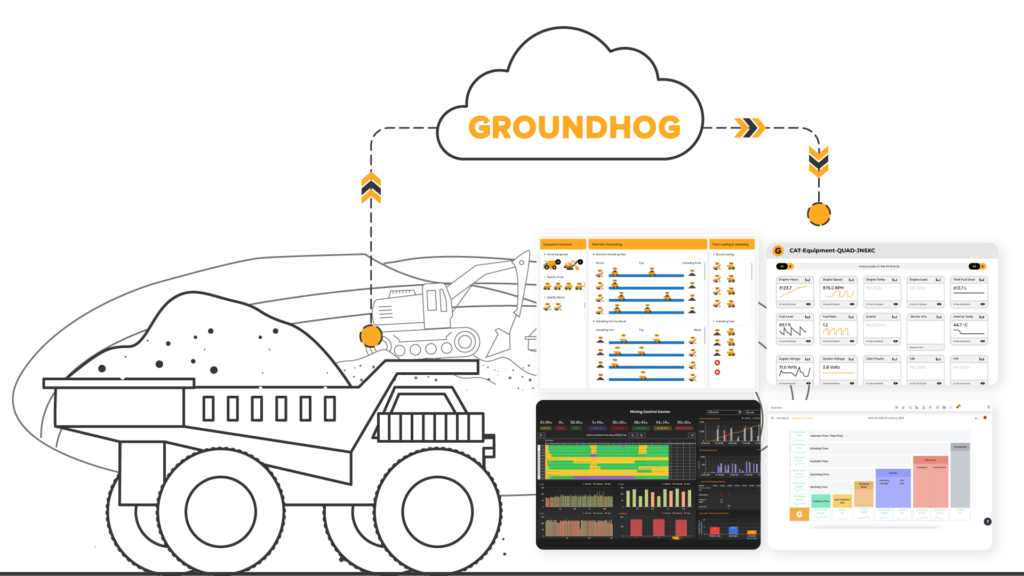

GroundHog GRYD is an integrated hardware solution designed for open-pit mining operations. It combines routing, CAN data extraction, and serial connectivity in one rugged device — enabling real-time communication between mining equipment, tablets, and GroundHog applications.

GRYD establishes a local, reliable network across the pit by linking diggers, trucks, and auxiliary machines through peer-to-peer mesh connections. Even when Wi-Fi is weak or unavailable, GRYD maintains continuous data flow between machines and the GroundHog platform.

Yes. GRYD connects directly to a machine’s onboard systems using CAN or serial interfaces. It eliminates the need for third-party devices, providing a seamless flow of real-time trip, load, and performance data to operators and dispatchers.

GRYD reads operational data such as load counts, haul cycle information, and equipment performance metrics. It integrates with high-precision GPS, VMI sensors, and weigh-scale systems to deliver accurate, real-time insights to GroundHog FMS.

Absolutely. GRYD automates equipment data collection and synchronization with GroundHog applications. This reduces human error, improves reporting accuracy, and allows shift supervisors to access real-time productivity and utilization data without manual updates.

Each GRYD unit can communicate directly with nearby machines, forming a local mesh network. This allows trucks and shovels to share data even when the main site network or Wi-Fi connection drops, ensuring uninterrupted fleet coordination.

Unlike traditional setups that rely on multiple external routers and third-party devices, GRYD consolidates all networking and data interface functions into a single, unified unit. This reduces latency, simplifies setup, and improves reliability in challenging mining environments.

Yes. GRYD was developed and manufactured in-house by GroundHog engineers, specifically for the harsh conditions of open-pit operations. Its ruggedized housing, stable connectivity, and expandable architecture make it ideal for high-demand mining applications.

GRYD’s modular, expandable design allows easy integration with future GroundHog systems and third-party tools. As mines evolve toward greater automation and digitization, GRYD provides a foundation for scalable, future-ready connectivity.

Reliable in-pit connectivity for all equipment.

Real-time data visibility for operators and supervisors.

Reduced downtime from network disruptions.

Automated data capture and faster shift reporting.

Rugged, purpose-built design for open-pit mining.