Introduction: Real-Time Monitoring as a Strategic Tool

In mining, every action must be precise to avoid delays, reduce safety risks, and minimize costly errors. Mistakes in this environment, such as sending a truck to the wrong location or overloading equipment, can have serious consequences, both financially and operationally. Real-time monitoring offers an effective solution, providing immediate insights that allow for instant adjustments and prevention of potential errors. Ultimately it keeps track on plan vs actual and minimizes deviation.

Real-Time Error Prevention Strategies

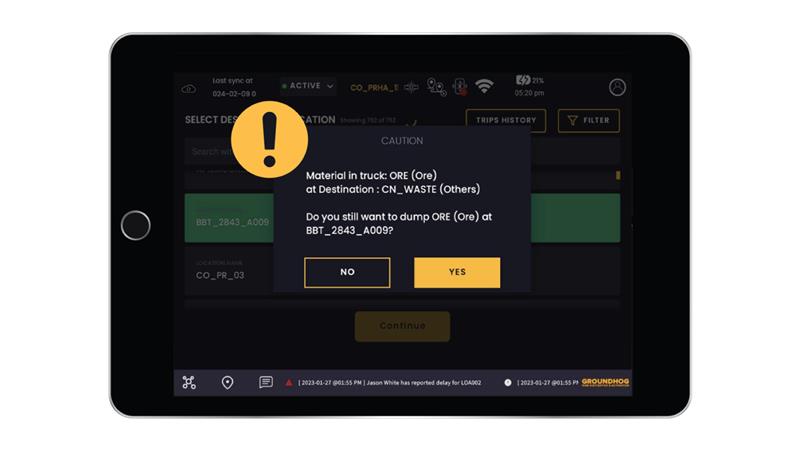

Proactive Error Alerts

In large mining operations, trucks and equipment operate across vast, complex landscapes. As per operation sequences source, destination and routes are planned. Without real-time monitoring, operators may occasionally miss a misrouting error or fail to notice when a truck heads toward the wrong site. Real-time alerts can immediately flag these issues. For example, if a truck is en route to the wrong stope, supervisors receive an instant notification, allowing them to redirect it in time. This reduces fuel costs, conserves resources, and ensures operational plans stay on track.

Location and Action Tracking for Equipment

Real-time tracking provides visibility into each piece of machinery’s location and function, ensuring operators are using equipment where it’s needed most. For instance, if any equipment completes its task, supervisors get the notification and can assign a new task. If some equipment is not running as per the working plan supervisor can divert it to the planned location. Thus, real-time tracking identifies this discrepancy quickly, prompting operators to stop, reassign, and continue to work in the correct area avoiding unnecessary non-productive work and eliminate possible delays. Real-time location tracking of people and equipment also enable prompt and safe evacuation in case of emergency.

Immediate Response to Deviations

Deviations in machinery performance—such as overheating, unexpected vibrations, or abnormal speed—often indicate underlying issues that could lead to costly breakdowns. GroundHog FMS + Telematics sends immediate notifications when deviations are detected, allowing for preventative maintenance before the problem escalates. This not only reduces downtime but also extends the lifespan of valuable mining equipment, ultimately leading to cost savings.

Conclusion: Real-Time Precision in Mining Operations

Real-time monitoring minimizes operational errors, prevents resource wastage, and improves safety by allowing for immediate intervention when issues arise. By adopting real-time monitoring, mining companies can avoid costly mistakes and ensure that resources are allocated effectively.