Digital Mining and the Path to Green Mining

Green mining begins with operational discipline. In this eBook, we

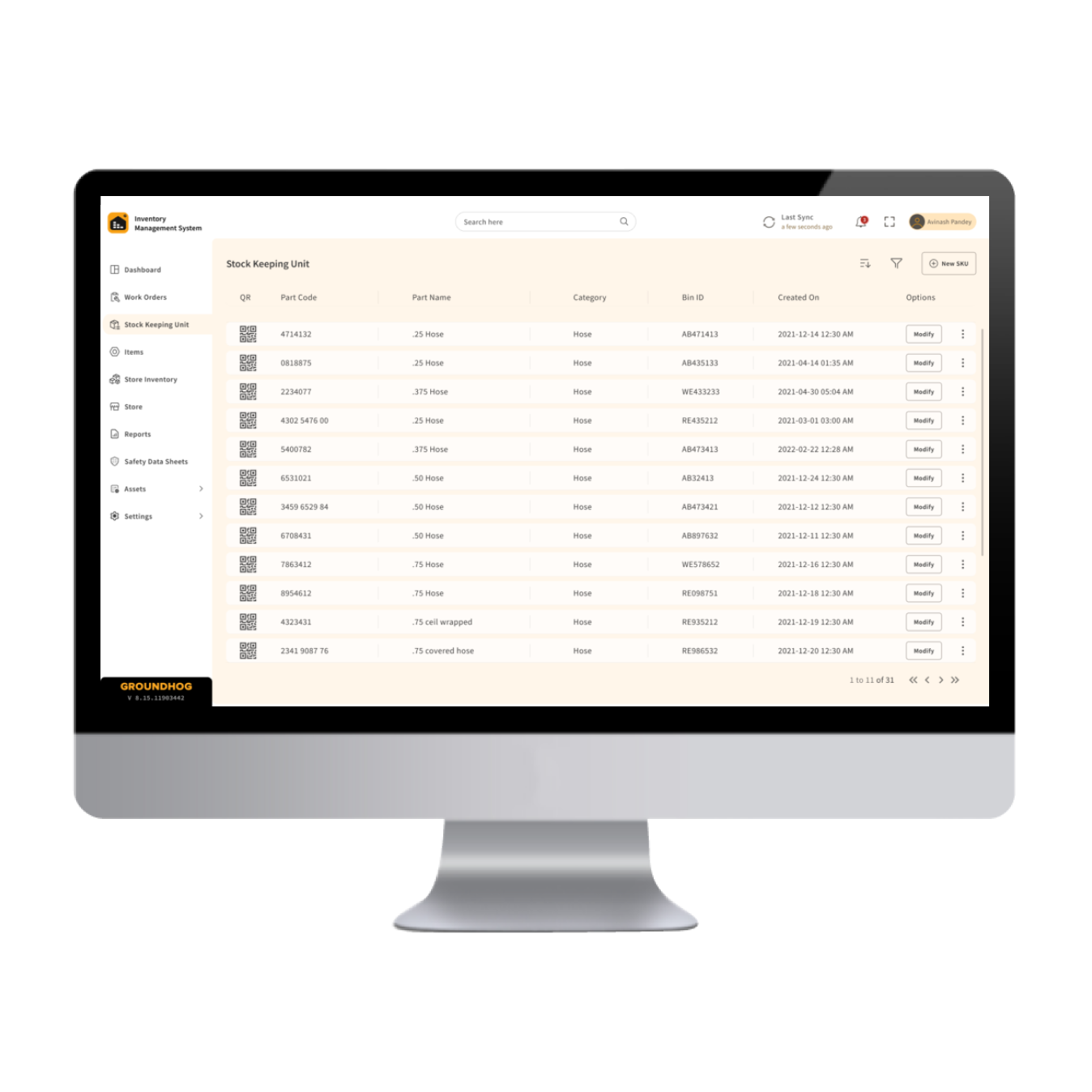

Optimize Inventory Visibility, Control Costs, and Boost Equipment Availability for Mining Operations

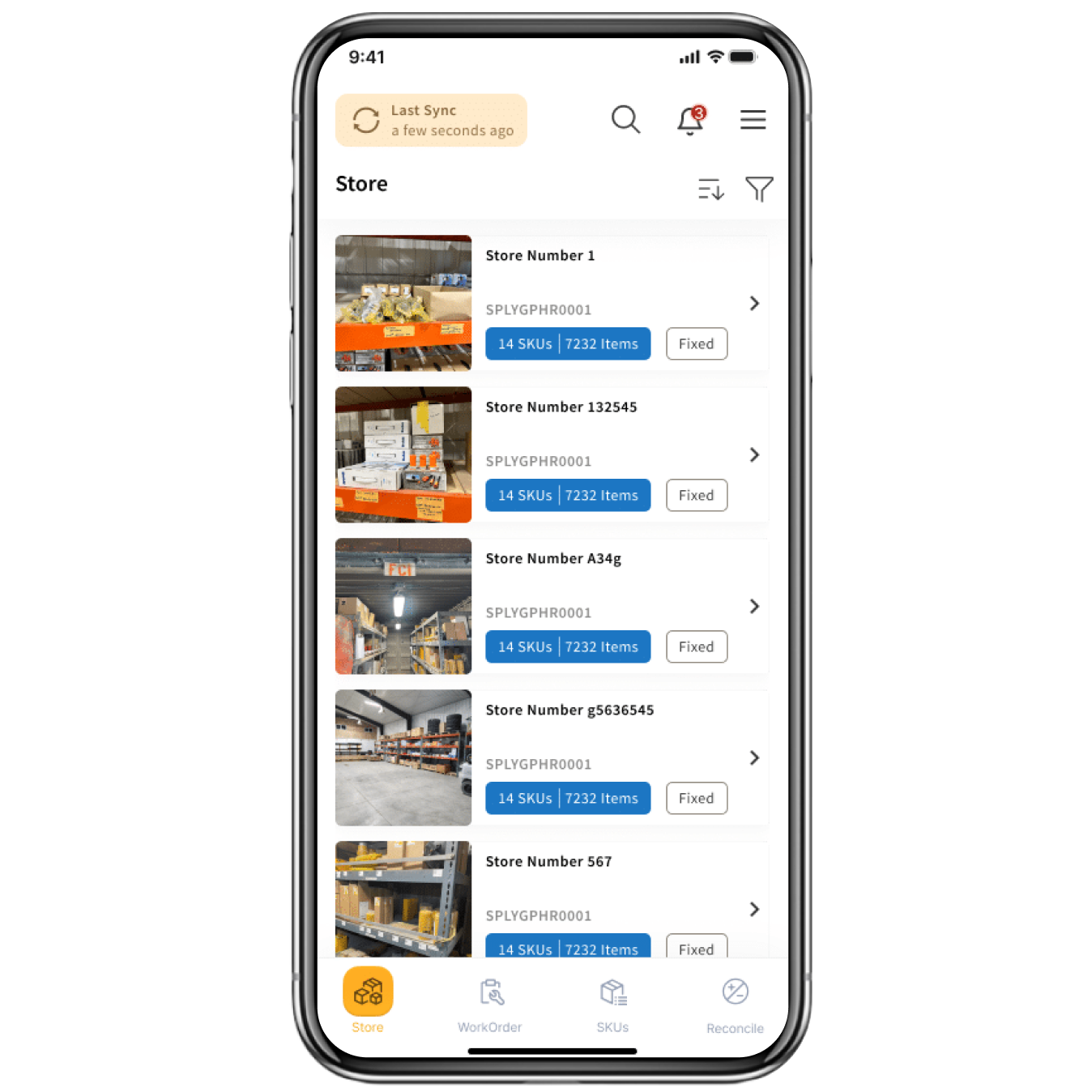

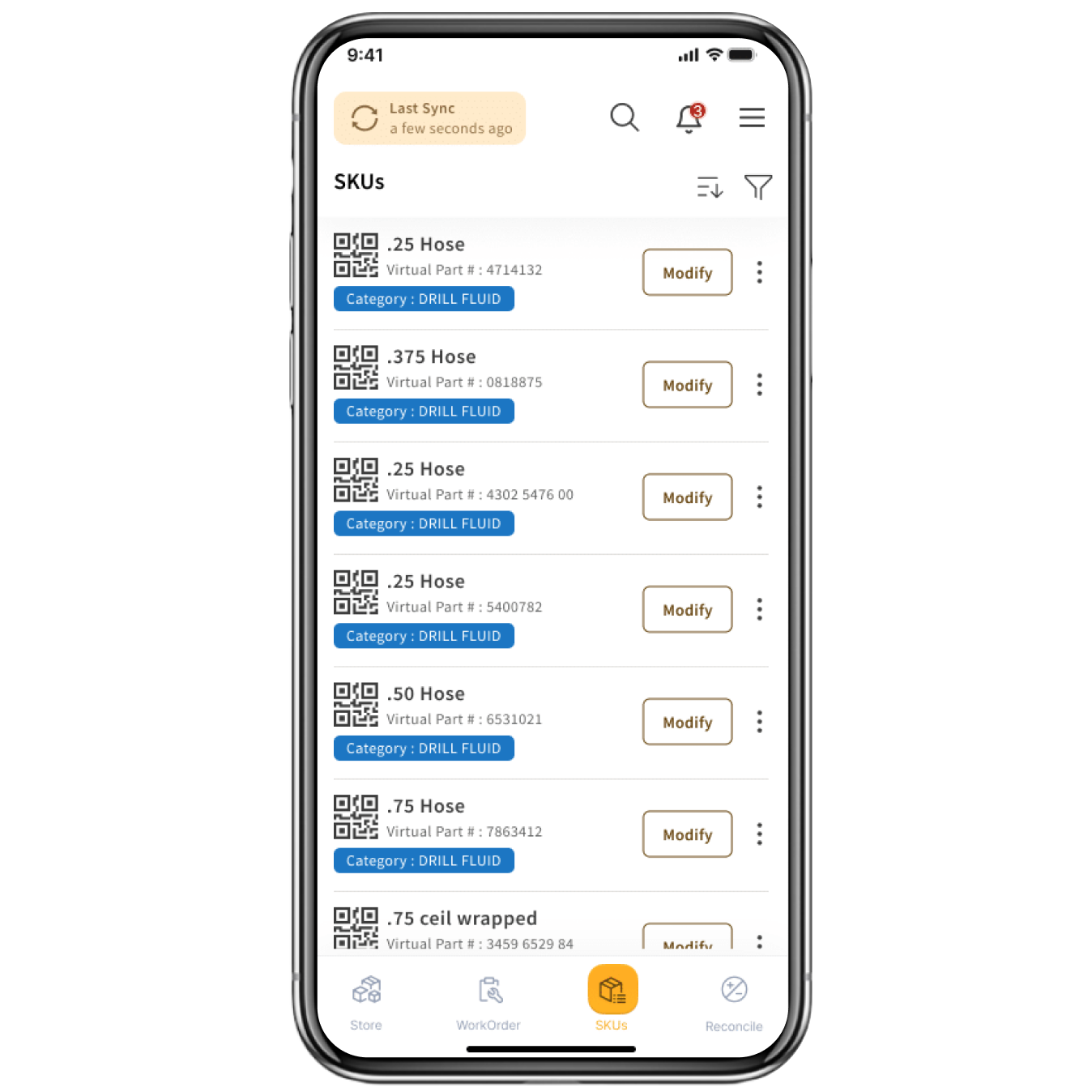

Real-time visibility of consumables across all locations

GroundHog’s Inventory Management System gives Operations Superintendents, Maintenance Supervisors, and Procurement teams a complete view of all consumables across all warehouses and laydowns, including underground locations. This accurate visibility helps improve inventory tracking and enhances operational efficiency.

Integrated tracking for accurate budgeting and expense management

GroundHog’s integration capabilities provide Mine Managers, Maintenance Planners, and Superintendents with precise tracking of consumable and maintenance costs. These insights are essential for accurate budget planning and cost control in mining operations.

Quick ordering and replenishment to minimize equipment downtime

By providing real-time visibility into inventory levels, GroundHog helps prevent downtime caused by stock shortages. With this system, operators, dispatchers, and procurement teams can quickly respond to parts needs, improving equipment availability.

Predict demand accurately to maintain optimal stock levels

GroundHog empowers Procurement Teams with tools to make data-driven decisions on inventory ordering, ensuring necessary supplies are available when needed. The system’s automated reporting also provides trends to help predict future demand.

Stay informed with automated notifications for balanced inventory management

GroundHog’s Inventory Management System keeps teams informed with notifications based on inventory thresholds. These alerts help prevent stock issues by notifying the team of low or high inventory levels or slow-moving items.

Achieve Greater Control, Lower Costs, and Improved Equipment Availability Across Mining Operations

Read related blogs and access useful links

Green mining begins with operational discipline. In this eBook, we

Consolidates-operational-kpi-library-for-mining-performance … Read More

Long-term mine plans don’t fail because of one bad assumption.

GroundHog offers real-time tracking of consumables across all warehouse and laydown areas, including underground locations. This visibility allows teams to access inventory data instantly, making it easier to manage resources efficiently.

GroundHog integrates with the Fleet Management Module to track consumables cost per tonne mined and with the Maintenance Module to record costs for maintaining each piece of equipment. This helps teams build accurate budgets and improve financial planning.

With GroundHog’s real-time inventory view, operators can quickly order parts, and procurement can immediately replenish stock, which reduces delays caused by stockouts. This streamlines access to parts and enhances equipment uptime.

GroundHog enables Procurement Teams to monitor demand and predict future needs accurately. With automated reports such as daily stock summaries and weekly usage trends, teams can make data-driven decisions on inventory ordering.

The system allows teams to set low-stock alerts to prevent understocking. GroundHog also notifies teams of high inventory levels or slow-moving items, helping maintain balanced and optimized stock levels.