2025 MSHA Violations: Why Reducing MSHA Violations Starts with Better Housekeeping, Machine Guarding, and Inspection Practices

In the first half of 2025, MSHA issued over 43,000

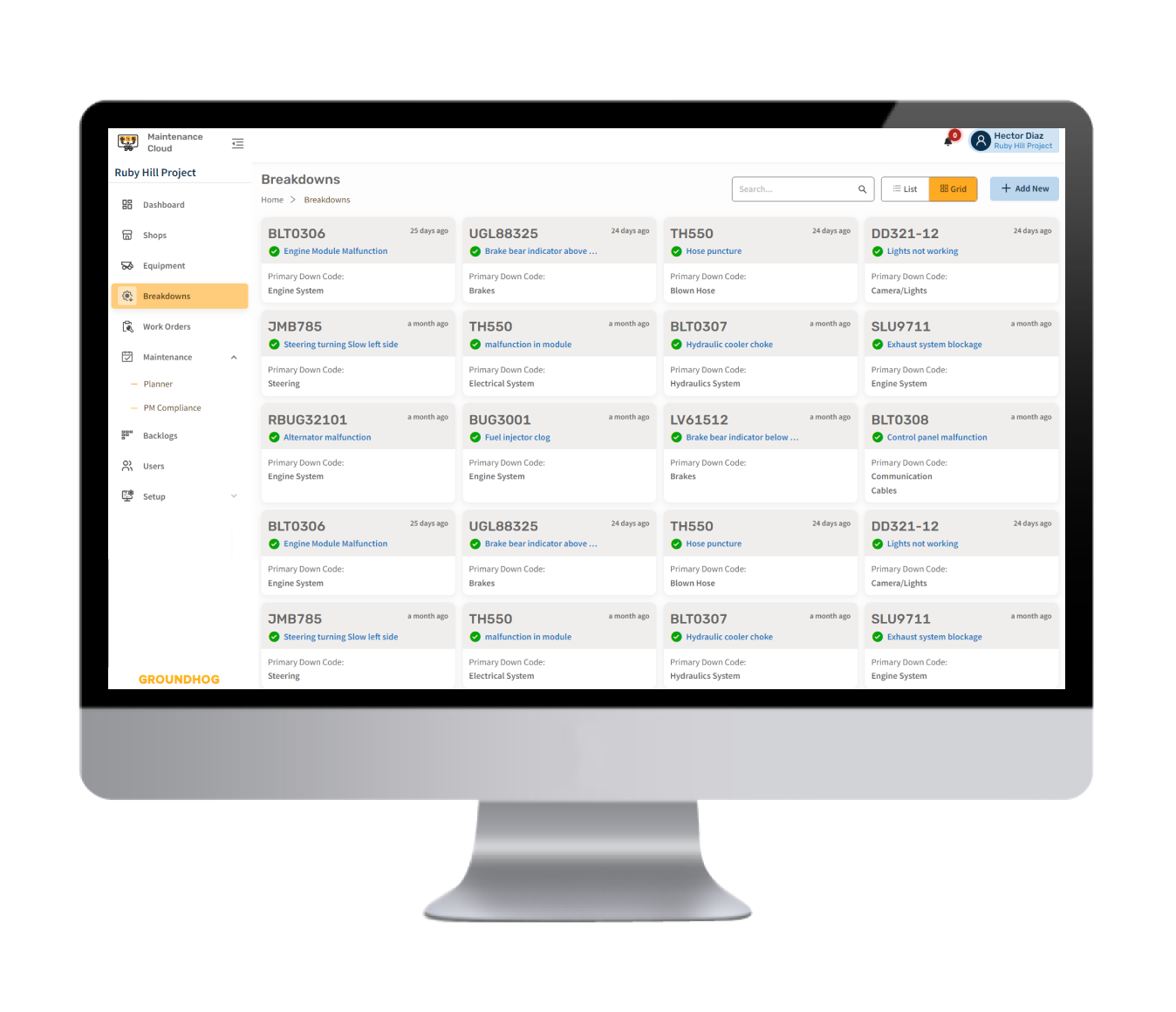

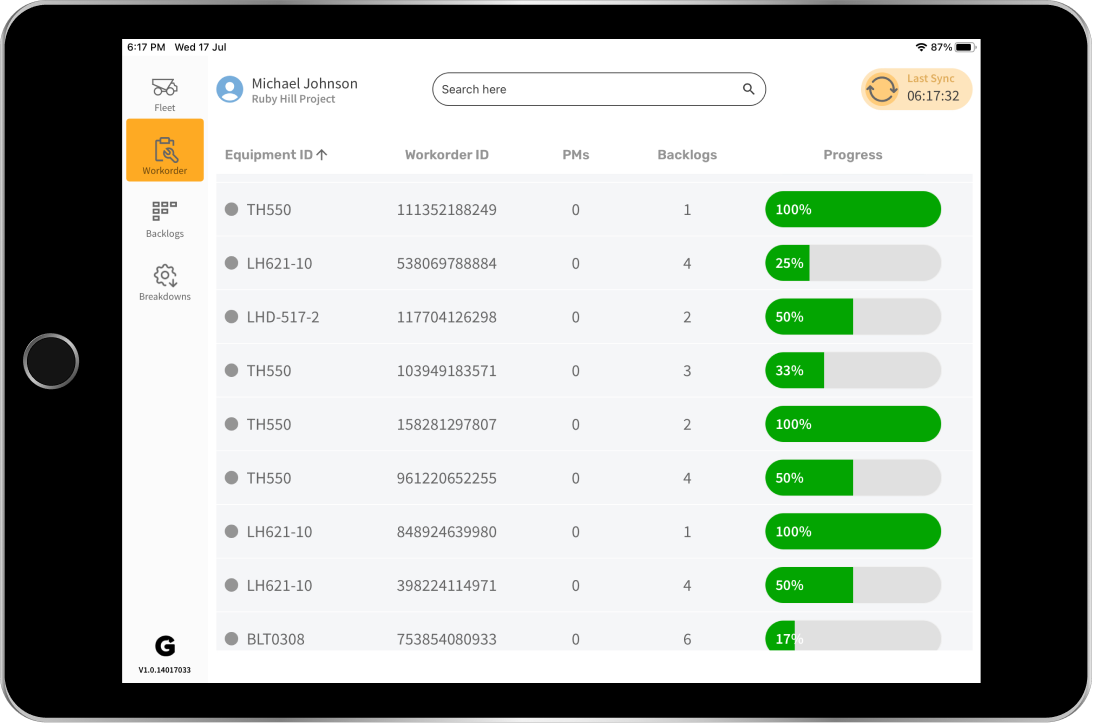

Quickly report breakdowns, prioritize by severity, promptly assign technicians, track real-time progress,

and document actions for continuous improvement.

Monitor, track, and Enhance Asset Performance with Just a Few Clicks

Rapidly report breakdowns, prioritize issues by severity for quicker resolution, and create work orders based on priority.

Instantly Monitor Repair Progress and Document Actions for Continuous Improvement.

Get a real time view of all your equipment and analyze, record and document data and turn them into actionable insights.

Explore Proven Strategies for Managing Breakdowns Effectively and Minimizing Downtime

Read Related Blogs and Access Useful Links

In the first half of 2025, MSHA issued over 43,000

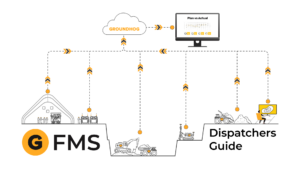

In mining, nothing moves without the dispatcher — and a

Long-term mine scheduling lays the foundation for achieving strategic business

Breakdown management involves the process of handling and resolving unexpected equipment failures or breakdowns. It includes identifying the cause of the failure, assessing the impact, and implementing corrective actions to restore equipment to operational status as quickly as possible.

Effective breakdown management is crucial in mining operations to minimize equipment downtime, prevent production delays, and ensure safety. It helps maintain productivity, reduces operational costs, and extends the lifespan of equipment by addressing issues promptly.

A CMMS system like GroundHog aids in breakdown management by:

GroundHog improves breakdown response times by providing real-time notifications to maintenance teams, offering mobile access to work orders and equipment information, and streamlining communication between field technicians and the central maintenance team.

Yes, breakdown management can be integrated with preventive maintenance strategies. By analyzing breakdown data, you can identify patterns and trends that inform preventive maintenance schedules, helping to reduce the frequency and impact of future breakdowns.

Training is essential for effective breakdown management as it ensures that maintenance personnel are equipped with the necessary skills and knowledge to quickly diagnose and repair equipment issues. Proper training helps in reducing response times, improving repair quality, and enhancing overall maintenance efficiency.

We invite you to request a tailored demo of our platform. Our team will provide a personalized walkthrough, showcasing how GroundHog can meet your specific needs and answer any questions you may have.

We look forward to demonstrating how GroundHog can transform your operations. If you have any questions before scheduling your demo, feel free to reach out to us at getStuffDone@groundhogapps.com. Let’s work together to enhance your operations!