California, 27 August 2024 —GroundHog, a leader in digital solutions for the mining industry, is happy to announce the release of its innovative ROM Loader Software, designed to optimize and streamline the critical process of material handling from the Run-of-Mine (ROM) pad to the crusher. This software provides precise tracking, blend management, and real-time insights, significantly improving overall productivity, resource utilization, and cost management. This comes as a part of our comprehensive suite of applications targeting various areas of Fleet Management.

Enhancing Safety and Compliance with GroundHog ROM Loader Software

The ROM Loader Software by GroundHog enhances operational efficiency and significantly improves safety and compliance in mining operations. The software helps ensure that all material handling processes adhere to strict safety guidelines and regulatory requirements by providing real-time monitoring and automated alerts. Additionally, the integration of advanced data analytics allows mining companies to continuously monitor and optimize their operations, reducing the risk of human error and improving overall safety standards. This focus on safety, alongside efficiency, sets the ROM Loader Software apart in the mining industry.

Understanding the ROM Pad

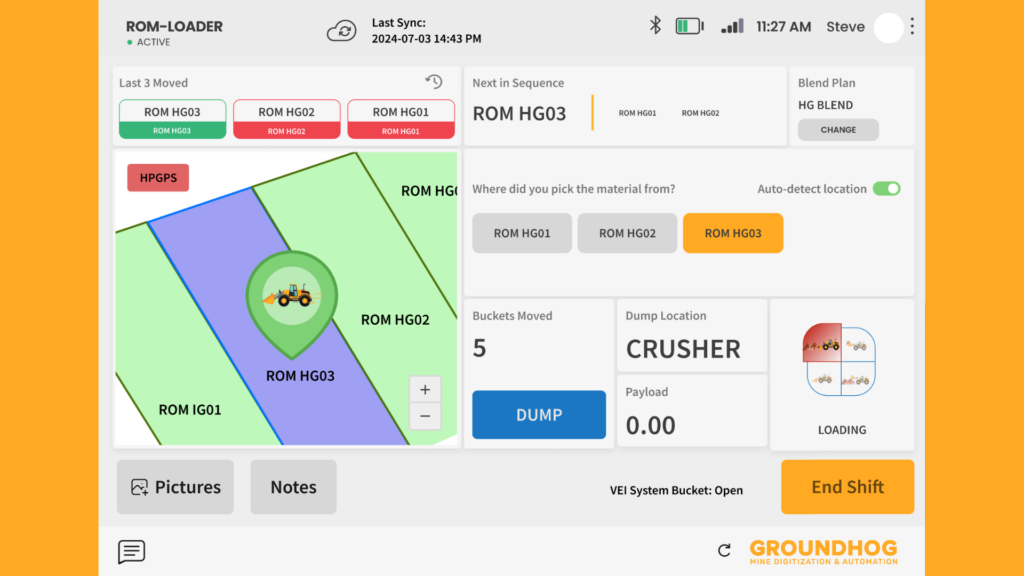

The ROM pad is where raw materials, including low, medium, and high-grade materials, are stored in organized blocks. The new ROM Loader Software integrates seamlessly with wheel loaders to manage these materials effectively, ensuring the correct blend of ores for processing.

Key Use Cases of ROM Loader Software

- Blend Sequence Management:

Operators receive a blend plan at the start of each shift, dictating the sequence for loading materials. The software ensures adherence to this plan, optimizing the ore blend for processing. - Real-Time Alerts:

If an operator deviates from the blend sequence, the software immediately alerts them, ensuring that the correct materials are loaded in the proper order. - Accurate Payload Tracking:

The software accurately tracks the amount of material being loaded into the crusher, providing precise data on payloads to improve resource management. - Stockpile Management:

Once the material is moved to the crusher, the software automatically deducts it from the stockpile records, maintaining accurate and up-to-date balances. - Sequence Tracking:

The software replaces traditional paper-based tracking with a digital system that accurately ensures operators load from the correct block and follow the blend plan. - Time Utilization Model (TUM):

With TUM, the software tracks details like vehicle breakdowns, blend plan changes, and non-productive time, offering insights into operator efficiency and productivity.

Satish Penmetsa, CEO of GroundHog, stated, “Our ROM Loader Software represents a significant leap forward in mining operations, offering unmatched precision and efficiency. By integrating this software into your operations, you can ensure optimal resource utilization, maintain quality control, and achieve higher productivity with reduced operational costs.”

The ROM Loader Software is now available for deployment. For more information or to schedule a demo, please visit our website at groundhogapps.com

About GroundHog:

GroundHog is a leading provider of digital solutions for the mining industry. Focusing on innovation and customer success, GroundHog offers a range of products designed to improve operational efficiency, safety, and productivity. From fleet management to production optimization, GroundHog is dedicated to helping mining companies achieve their goals.

For more information, please visit www.groundhogapps.com or contact: getStuffDone@groundhogapps.com