The richest vein in mining today isn’t a mineral – it’s data. AI is turning that data into actionable insights, and the industry is at a critical inflection point. The latest 2025 AI Index Report highlights how, in 2024, AI adoption accelerated at an unprecedented rate across industries. What was once on the margins has become “a central driver of business value”. Millions now use AI in daily work, and businesses everywhere are reaping the rewards. The question for mining leaders is: will we lead this transformation or fall behind?

AI Adoption: From Fringe to Mainstream Urgency

The AI Index data indicates that 2024 marked a turning point. After years of cautious integration, businesses have fully embraced AI, driving a surge in productivity and innovation. This is not a distant future scenario; it is happening right now. AI is integrated into daily operations across various industries, from manufacturing to finance, analysing real-time data and influencing decision-making. For the mining sector, this increase in AI adoption presents a critical opportunity. Early adopters in other industries are advancing with greater efficiency and agility. The mining industry cannot remain in an analog state while competitors, as well as suppliers and customers, transition to digital. The message is straightforward: Embrace AI or risk falling behind in safety, costs, and production.

“AI has moved from the margins to become a central driver of business value.” Stanford AI Index 2025.

Miners have consistently been at the forefront of innovation, evolving from mechanisation to automation, and now AI represents the next significant advancement. Adapting to this change is essential for survival. Those mines that embrace this trend will establish the performance standards for the future.

Miners have always been innovators – from mechanisation to automation – and today AI is the new lever for a quantum leap. Embracing this shift is not optional; it’s existential. Mines that ride this wave will set the performance benchmarks of tomorrow.

Productivity & Efficiency – Hitting New Highs

If the swift integration of AI is the rhythm, then the resulting productivity improvements are the song. The AI Index report, which analysed data from over 200,000 professionals, revealed consistent enhancements in output ranging from 10% to 45% when AI is utilized. It’s worth noting that even the smallest improvements recorded were in the double digits, while the most significant reductions in work time for achieving the same results were almost halved. This is not mere exaggeration; it reflects real outcomes. For instance, one study indicated that a generative AI assistant enabled customer support teams to resolve issues 14% more quickly per hour, effectively providing an additional hour of productivity for every seven hours worked. Other studies corroborated these findings, showing that routine tasks like document editing became 10–13% faster, email processing improved by 11%, and specialized roles experienced remarkable advancements, such as sales teams responding 39% more quickly.

Now, translate these gains to a mine site:

- Increased Output, Reduced Time:

A 10–45% improvement in efficiency could allow you to transport considerably more ore with the same equipment or reach production goals ahead of schedule. Picture wrapping up a shift and discovering you’ve extracted nearly 50% more than before – that’s the potential benefit AI can provide.

- Operational Excellence:

These enhancements arise from AI streamlining processes, minimizing downtime, and supporting decision-making. It’s akin to having a constant assistant evaluating haul truck data, drill metrics, and crew performance to eliminate delays and recommend optimizations in real time.

- Workforce Empowerment:

Instead of substituting human workers, AI enhances their productivity. Just as office teams managed increased volumes of tickets or emails with AI assistance, mining crews can undertake more tasks with reduced complications. This technology alleviates engineers and supervisors from administrative burdens and data analysis, allowing them to concentrate on more valuable activities, such as optimizing cycle times or refining preventive maintenance schedules.

The bottom line: AI makes mines more productive and efficient. In an industry where margins are thin and variability is high, these gains directly bolster the bottom line. Every percentage point of improvement in equipment uptime or shuttle trip count per shift can translate to millions in value over a year. AI is the toolkit to capture those gains consistently.

Real-Time Data & Short Interval Control – From Reactive to Proactive

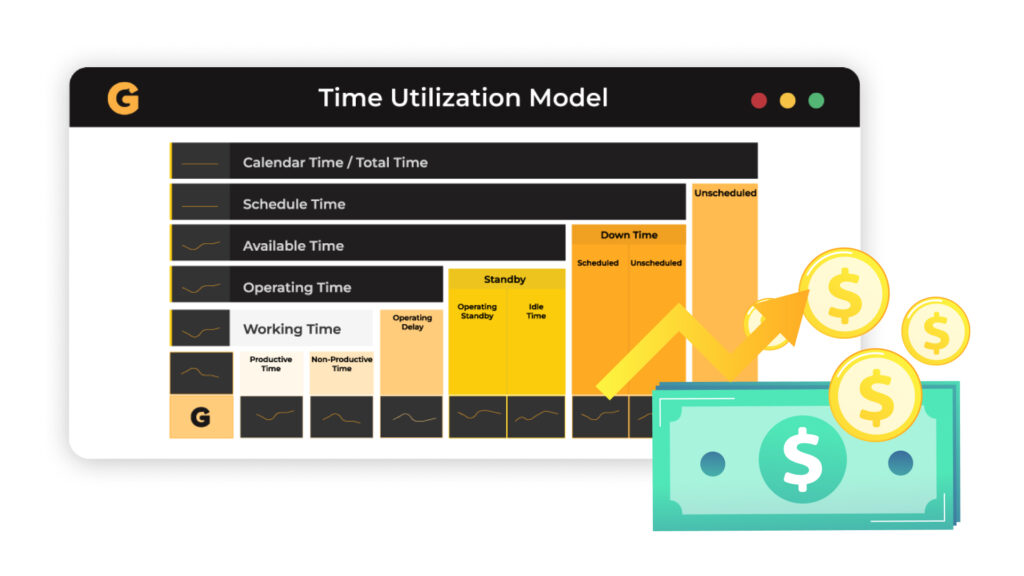

Mining operations have traditionally run on end-of-shift reports and end-of-month reconciliations. By the time issues surface, the opportunity to fix them has passed. Enter real-time data insights and Short Interval Control (SIC) – a game-changer for how mines are managed. Short Interval Control is a structured process of making brief, frequent check-ins during a shift to review progress and address problems in the moment (Short Interval Control with GroundHog – Groundhog Apps). Instead of waiting 12 hours to discover a truck was down or a face underperformed, supervisors get updates hour-by-hour and can course-correct immediately. As the GroundHog mining eBook puts it, SIC enables real-time adjustments rather than waiting for the shift-end report (Short Interval Control with GroundHog – Groundhog Apps).

This is where AI and digitisation shine:

- Continuous Visibility:

With IoT sensors on equipment and digital apps in operators’ hands, mines can stream data on drilling rates, loading times, haul speeds, etc., in real time. AI systems crunch these streams instantly, flagging deviations or delays. If a loader is idling too long or a conveyor stops, management knows now, not tomorrow.

- Rapid Response:

Those mid-shift check-ins powered by live data mean you can dispatch a spare truck at 2 PM when one breaks down at 1:50 PM. You can re-route crews, adjust drill patterns, or call maintenance before a small issue snowballs. This tight feedback loop is the essence of short-interval control – staying ahead of the curve every hour. Mine’s moving to this mode have seen huge improvements in tonnage per shift and equipment utilisation.

- AI-Driven Insights:

The volume of data in a modern mine is enormous. AI algorithms help make sense of it, detecting patterns no human eye could catch. For example, AI can recognise that a particular dig unit is consistently 5% below output whenever a certain ore type is encountered and suggest an optimal blast or dig technique. It’s like having a virtual supervisor monitoring all aspects of operations simultaneously, 24/ (AI: The new safety inspectors for mining equipment – International Mining) (AI: The new safety inspectors for mining equipment – International Mining.)

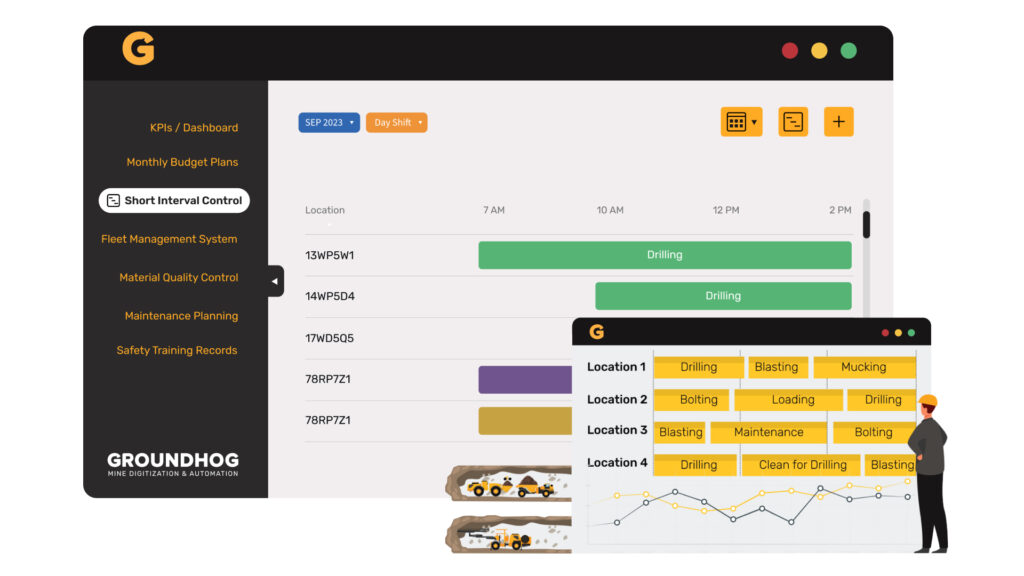

GroundHog’s digital mining platform is a key enabler here. GroundHog’s Short Interval Control tools give front-line supervisors and management a live dashboard of the shift. Every scoop, truck, and sensor is connected to a central system, delivering immediate insight and enabling on-the-fly decisions. The result? Deviations are caught early and corrected, plans are optimised in real time, and no hour is wasted. By empowering mines to be proactive instead of reactive, GroundHog’s SIC framework has been shown to raise overall equipment effectiveness and yield measurable productivity gains within months (Short Interval Control with GroundHog – Groundhog Apps). This is transformative – it’s a shift from fighting fires after the fact to preventing them in the first place.

Safety & Asset Management – No Trade-Off Needed

Digitisation and AI aren’t just about more output; they’re about safer and smarter operations. In mining, safety is paramount – every incident prevented is priceless. The good news is that the same technologies boosting productivity also enhance safety and asset reliability:

- Predictive Maintenance & Asset Health:

AI can analyse equipment telemetry (vibration, temperature, pressure, etc.) to predict failures before they happen (AI: The new safety inspectors for mining equipment – International Mining). Instead of a haul truck brake failing on a ramp (with potentially catastrophic results), AI-driven systems will have flagged abnormal brake temperatures hours or days earlier so you can fix it proactively. According to industry data, AI-powered predictive maintenance can reduce unplanned downtime by up to 50% and significantly cut maintenance costs, all while increasing overall productivity (Predictive Maintenance: How AI Reduces Downtime and Boosts Productivity in Manufacturing). In practice, this means fewer surprise breakdowns, more scheduled fixes, and extended equipment life – a huge win for asset management. Every hour of downtime avoided is saved production, and every failure averted is a safer shift for everyone.

- Real-Time Hazard Detection:

Computer vision and IoT sensors, coupled with AI, serve as tireless sentinels for safety. They can detect a hazard on a work site – whether it’s a person too close to heavy machinery, an unsteady highwall, or a driver showing signs of fatigue – and trigger immediate alerts. AI doesn’t get tired or distracted; it’s always monitoring. International Mining recently reported how AI image analysis can spot cracks or defects in equipment that humans might miss, and IoT-linked AI can detect anomalies early to prevent breakdowns and accidents that jeopardise worker safety (AI: The new safety inspectors for mining equipment – International Mining). In essence, AI acts as an extra safety inspector on your team, one that can see the subtle warning signs of danger in mountains of data.

- Short Interval Control for Safety:

SIC isn’t just about production – those regular check-ins include safety checks. Is ventilation sufficient? Are there any geotechnical warnings? AI can continuously analyse environmental sensor data (like gas levels, ground stability) and production conditions. If something falls outside safe parameters, the team can respond immediately. This minimises exposure to risk because issues are caught in minutes, not at the shift’s end. One mining technology survey in 2024 found 96% of mine employees believe AI will have a noticeable positive impact on safety (The impact of AI on the mining sector – Mine | Issue 145 | October 2024) – and we’re already seeing it.

- Holistic Risk Management:

By evaluating multiple data points (equipment age, usage patterns, operator behaviour, etc.), AI can assign risk scores to activities or machinery. This helps prioritise inspections and maintenance on the most critical asset (AI: The new safety inspectors for mining equipment – International Mining). In practice, it means limited resources (maintenance crews, inspection time) are focused where they’ll avert the most danger. The AI Index report underscores that responsible AI and “AI’s expanding role in business” go hand in hand (hai_ai_index_report_2025.pdf.pdf) – in mining, a big part of that role is making operations safer without sacrificing productivity.

The synergy is clear: AI makes mines both safer and more efficient. By preventing accidents and unplanned outages, you not only protect your people, you also ensure high equipment availability and steady production. In fact, AI-driven inspection regimes yield significant cost savings by reducing downtime and minimising the risk of accidents (AI: The new safety inspectors for mining equipment – International Mining). Fewer breakdowns and incidents mean fewer expensive stoppages and investigations. It’s a virtuous cycle of “safety begets efficiency”: every near miss avoided or breakdown prevented keeps the operation running smoothly and profitably.

GroundHog: Enabling the AI-Driven Mine

All these opportunities – real-time insights, short interval control, predictive safety – need the right tools to become a reality. This is where GroundHog’s suite of digital mining applications comes in. We’ve built our platform specifically to help mines harness AI and automation quickly and effectively. From underground operations to open-pit mines, GroundHog provides the digital backbone for an AI-enabled mine:

- Unified Data Platform:

GroundHog connects equipment telemetry, sensor feeds, and mobile operator inputs into one system of record. This real-time mine data is the fuel for AI analytics and instant decision-making on-site.

- Short Interval Control Apps:

GroundHog’s SIC module empowers shift bosses with live dashboards of production KPIs and alerts. It’s designed for ease of use in the field, so that doing those brief check-ins and adjustments is seamless. Our users see what’s going on as it happens – and can act on it. No more waiting for the end of shift to discover problems; GroundHog brings issues to light when there’s still time to fix them.

- AI-Powered Insights:

We integrate advanced analytics and AI (from predictive maintenance algorithms to smart scheduling) into our tools. The platform can highlight underperforming areas, predict maintenance needs, and even optimise haul routes or loader-truck pairings. It’s like having a team of data scientists monitoring your mine 24/7, but packaged in intuitive software for operators and managers.

- Tangible Results:

We know mining is about results – tonnes, hours, and safety metrics. GroundHog has consistently delivered tangible improvements for our clients. Operations that implement our digital SIC and fleet management systems often see productivity jump within a few month (Short Interval Control with GroundHog – Groundhog Apps). One example: by tracking and responding to delays in real time, a mine was able to add several extra loads per shift that used to be lost in wait times and coordination lags. Maintenance planners using GroundHog have cut downtime by catching issues earlier, scheduling repairs during already planned stops, and avoiding surprise failures. And because everyone from the pit floor to the control room is connected, mines also report better teamwork and accountability – everyone has the data, so everyone stays on the same page working toward the target.

GroundHog’s mission is to make this AI-driven transformation accessible and profitable for every mining operation. We act as the enabler, providing the digital tools and expertise so that your team can focus on mining, not wrangling data or debugging tech. The result is digital mining operations that run safer, smoother, and smarter – delivering more value with every shift.

Lead the Change – A Call to Action for Mining Leaders

The mining industry is standing on the cusp of a new era. Just as mechanisation and automation reshaped mining in decades past, AI-powered digitisation is set to redefine what productive and safe mining looks like in the 2020s and beyond. The 2025 AI Index Report underlines a simple truth: the AI revolution is here, now, not in some distant future. The winners of this revolution will be those who act with urgency and purpose.

For mining executives, senior engineers, and decision-makers, the mandate is clear: lead this change. Embracing AI and digital tools is no longer about gaining an edge – soon it will be about survival. But this moment is also a huge opportunity. The gap between those who have modernised and those who haven’t is wide, which means early movers can leap ahead of competitors. We have the chance to set new performance records, to achieve zero-harm operations, and to future-proof our mines against volatile markets and labour shortages.

Now is the time to act. Start by exploring how these AI trends can apply to your mine sites:

- Benchmark your current operations – where could a 10-20% efficiency gain make a game-changing difference? Chances are everywhere.

- Identify the quick wins with AI: Perhaps it’s improving truck dispatch, augmenting your geologists with AI analysis, or automating routine safety checks. Prioritise a pilot project and start small, think big, and scale fast.

- Most importantly, get the right partner. You don’t have to do this alone or build everything in-house. GroundHog is here to help you operationalise AI in your mine. We’ve done the groundwork in digitising mines and can accelerate your journey.

Mining leaders – the future is beckoning. It’s time to move beyond reports and conversations and put AI to work on the ground. Those who do will drive unprecedented value and set the standard for the industry. Those who don’t risk being left in the dust of history, surpassed by smarter, faster, safer operations.

Are you ready to lead this digital mining revolution? ⚡ Let’s make it happen. GroundHog is ready to partner with you on this journey – reach out, ask us how, and let’s transform your mine. The technology is here, the benefits are real (AI: The new safety inspectors for mining equipment – International Mining), and the time for action is now. Let’s dig in and build the future of mining together. ⛏️🤝

(References: Stanford University – 2025 AI Index Report; International Mining Magazine; GroundHog “Short Interval Control in Mining” eBook, 2024.)

About the Author: Jason Aucamp

Mining Executive | Digital Transformation Strategist | Sustainability Advocate

With over two decades of experience in the mining industry, Jason Aucamp stands out as a leader in driving innovation and sustainable practices. His career encompasses leading multidisciplinary teams and managing large-scale mining projects, consistently focusing on enhancing productivity and environmental stewardship.

Jason has been instrumental in implementing strategies that optimize resource utilization and integrate cutting-edge technologies into mining operations. His expertise spans both the technical and commercial facets of the industry, enabling him to deliver comprehensive solutions that address contemporary mining challenges.

A prominent speaker at industry events, Jason shares insights on the convergence of digital technologies and sustainable practices in mining. His presentations emphasize the importance of collaboration and innovation in achieving operational resilience and long-term growth.

Currently serving as the regional Director at GroundHog and as a Technical Advisor at Montero Mining and Exploration Ltd., Jason continues to influence the mining sector’s evolution towards more sustainable and technologically advanced methodologies.