Digital Mining and the Path to Green Mining

Green mining begins with operational discipline. In this eBook, we

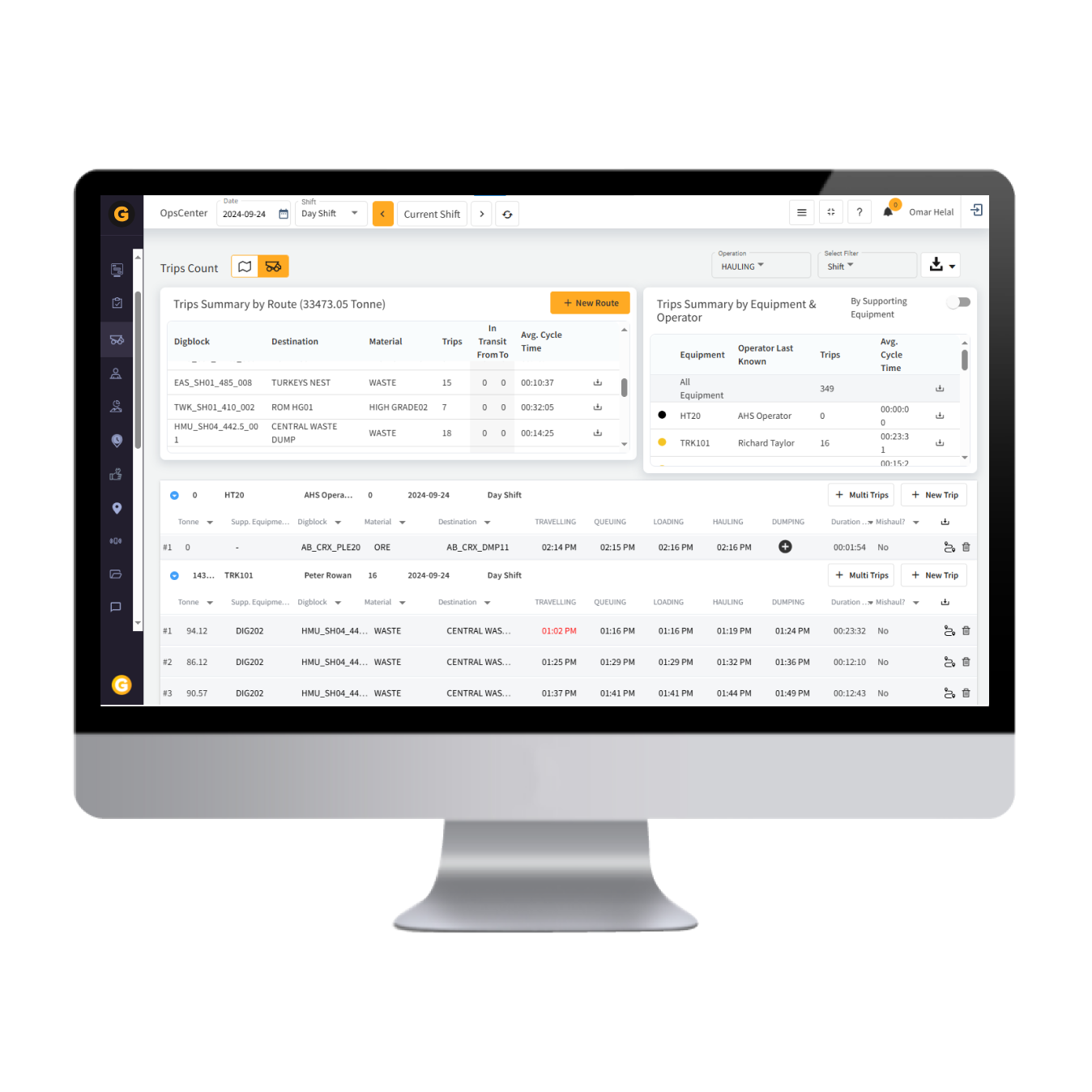

GroundHog’s Open Pit Fleet Management System is designed specifically for mining contractors, offering powerful tools to improve productivity, reduce costs, and streamline operations

Increase Efficiency Across Your Fleet

GroundHog’s Fleet Management System is built to improve fleet efficiency, helping you increase tonne-km/hour and overall productivity. Real-time monitoring and route optimization enable faster cycle times and more efficient material movement, ensuring that your fleet is working at its maximum potential.

Flexible Pricing Based on Project Scale and Duration of Contracts

Our system operates on a pay-per-project model, reducing upfront investment costs for mining contractors. You only pay for the system based on the scale of your project and duration of contracts, allowing you to better manage your budget. GroundHog annual and quarterly subscription model enable the contractors to effectively use the software based on their contract duration.

Touchless, Operator-Independent Trip Tracking

Say goodbye to manual trip counting! GroundHog’s automated load trip counting system uses advanced geofencing and GPS technology to track trips accurately and reliably. The system is completely operator-independent, ensuring consistent trip data without manual input.

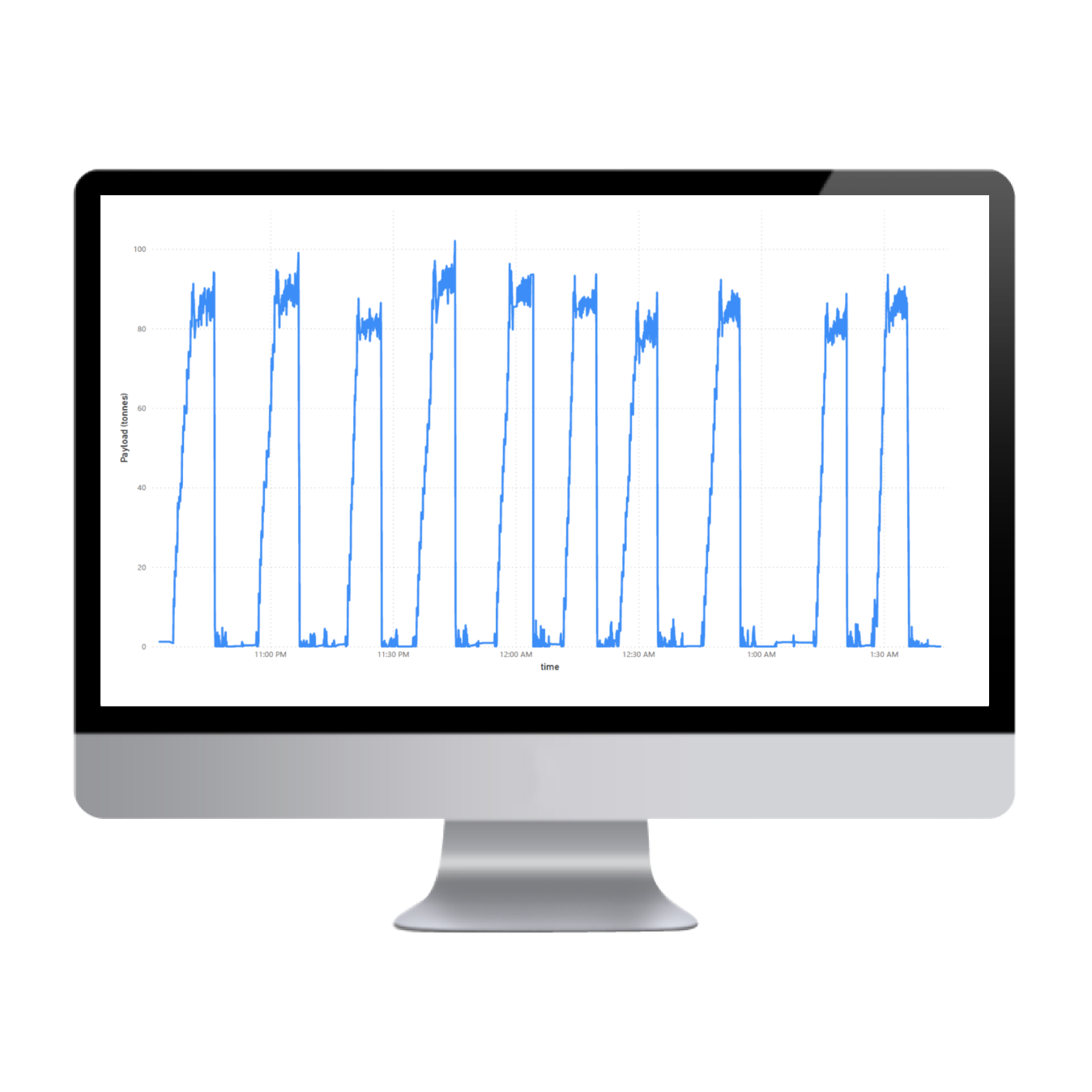

Real-Time Payload Data for Improved Decision-Making

Integrate GroundHog’s system with telemetry for real-time payload monitoring. This enables contractors to measure payloads accurately and track material movement.

Invoicing Based on Tonnage and Distance

GroundHog’s system automates invoicing based on actual tonnage moved and kilometers traveled, ensuring accurate and transparent billing.

Maximize Efficiency, Minimize Costs – The Ultimate Fleet Solution for Mining Contractors

Green mining begins with operational discipline. In this eBook, we

Consolidates-operational-kpi-library-for-mining-performance … Read More

Long-term mine plans don’t fail because of one bad assumption.

GroundHog’s system optimizes fleet efficiency by providing real-time monitoring and route optimization. This results in faster cycle times and more efficient material movement, helping you increase tonne-km/hour and overall productivity. By reducing idle time and maximizing the productivity of each vehicle, the system ensures that your fleet operates at its full potential.

GroundHog’s pay-per-project pricing model reduces upfront costs by charging you only based on the scale of your project. This flexible approach allows contractors to better manage their budgets, minimizing financial risks and ensuring that you’re paying only for what you need, whether for small or large projects.

GroundHog’s automated load trip counting system uses geofencing and GPS technology to track trips without manual input, making it operator-independent. This ensures consistent, reliable trip data, removing the potential for human error and providing accurate insights into fleet performance.

GroundHog’s system integrates with telemetry to deliver real-time payload monitoring. This enables contractors to measure and track material movement accurately, optimizing load capacities and reducing downtime. With instant access to payload data, you can ensure that each trip is efficient and that vehicles are being fully utilized

GroundHog’s automated invoicing system calculates payments based on actual tonnage moved and kilometers traveled, ensuring transparency and accuracy. This streamlined process reduces administrative time, prevents billing disputes, and helps contractors receive payments faster by relying on real-time fleet data.