Digital Mining and the Path to Green Mining

Green mining begins with operational discipline. In this eBook, we

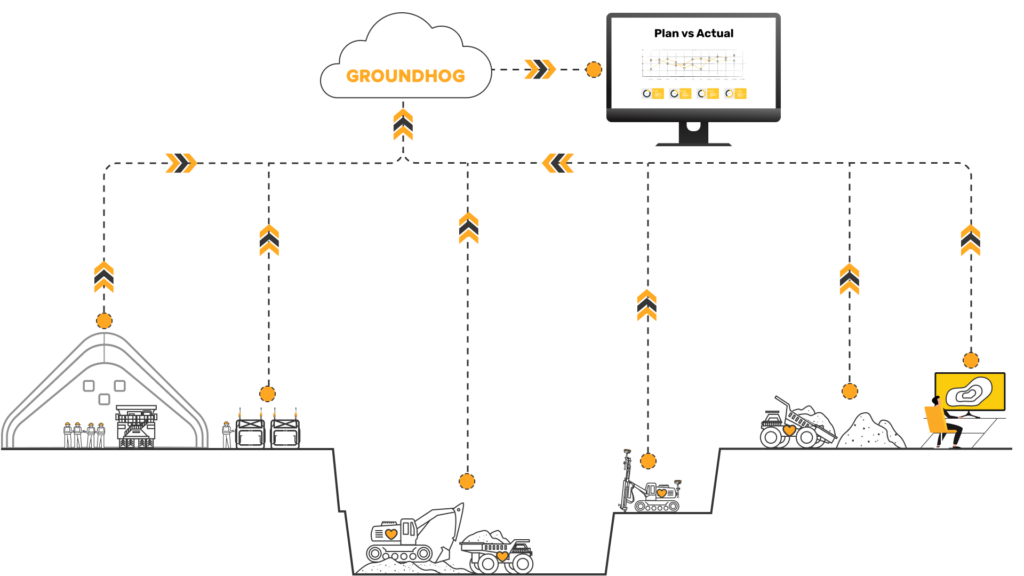

GroundHog’s Surface Fleet Management System delivers complete mine management from the production bench to the central office, continuously monitoring all surface activities to maximize ore recovery and equipment utilization.

GroundHog FMS Integrates with GroundHog SIC to Optimize Haul Truck Routing in Real-time.

Advanced AI based algorithms use real time loading and haulage performance data at each loading point to dynamically allocate Haul Trucks to Shovel/Front Wheel Loaders.

Real-time Recording of Production Data for Drilling, Blasting, Loading , and Hauling

Many mines use paper for data, causing errors. Digital capture improves accuracy in real-time.

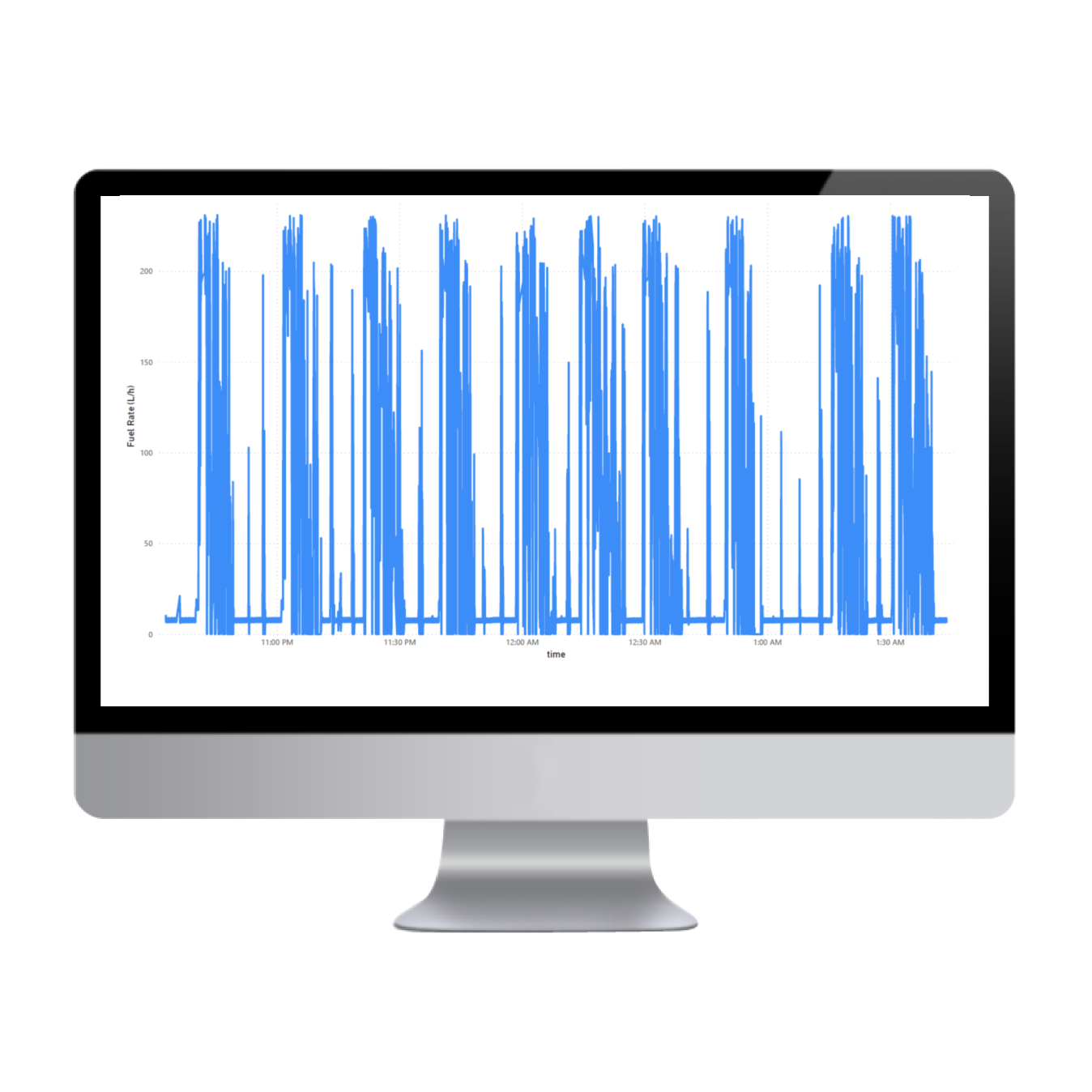

GroundHog’s FMS System Integrates with GroundHog Telemetry and Fuel Monitoring System to Prioritize Fuel Stops and Recommend Breaks to Maximize Production Efficiency.

GroundHog Fleet Management System integrates with GroundHog ‘s on-board Telemetry, Fuel Monitoring system and Payload Unit via Wi-FI to capture machine and payload data automatically and monitor asset health.

Track Material Flow With Precision for Accurate Blending, Timely Mill Delivery, and Better Grade Control.

With high precision technology and GPS, GroundHog FMS can track material from every dig block to stockpile and from every ROM Loader to crusher to meet mill’s blend plan.

Real-Time Monitoring, Automated Work Orders, and Performance Metrics for Optimal Efficiency

GroundHog FMS system tracks equipment metrics and data to optimize performance and increase uptime. Mine managers and maintenance teams monitor these metrics constantly via Power BI dashboards.

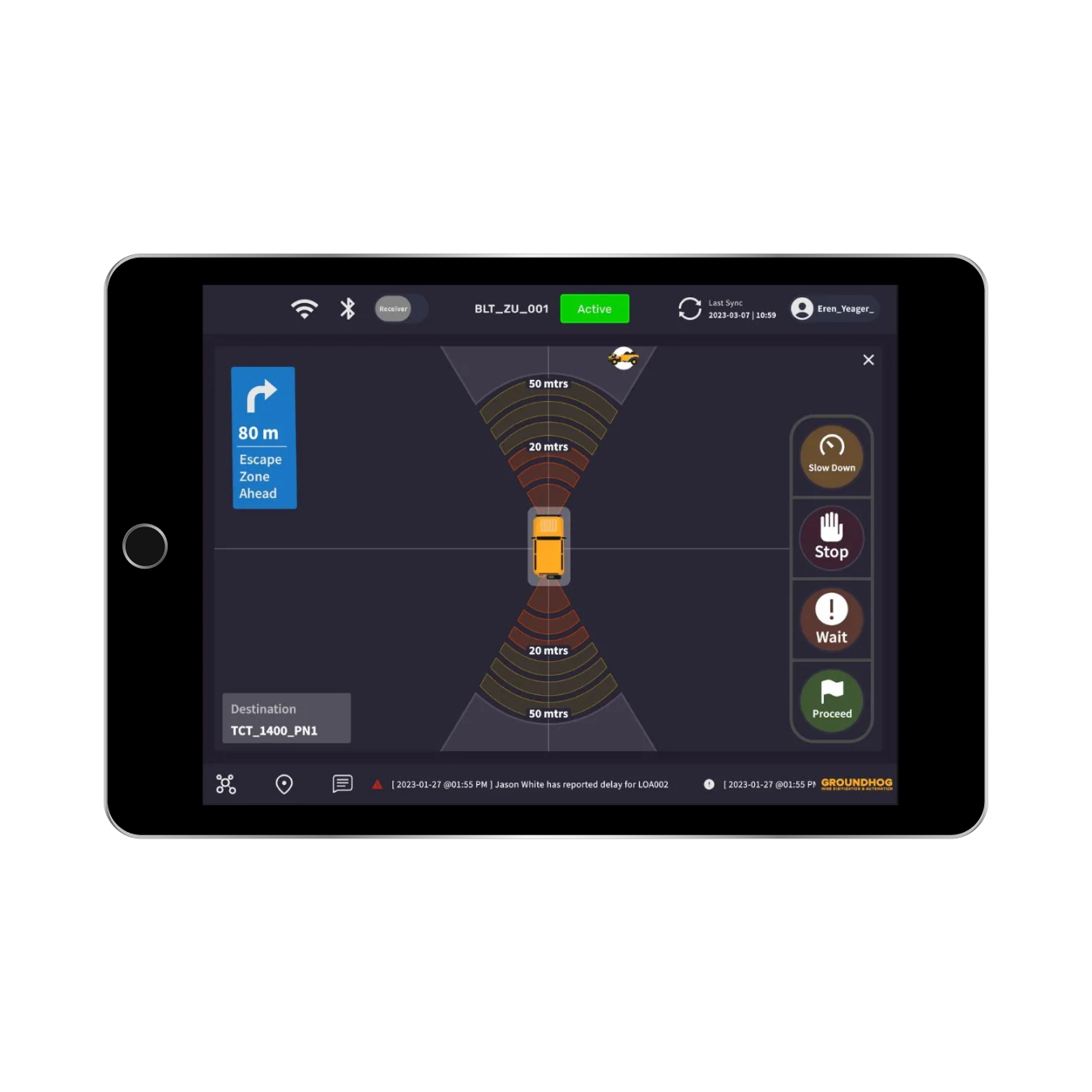

Real-time Location Tracking, Proximity Detection and Collision Alerts

Our advanced systems enhance situational awareness and operator safety by integrating real-time location tracking, collision prevention, and traffic management.

Eliminate Mis-Hauls and Enhance Blend Compliance!

Green mining begins with operational discipline. In this eBook, we

Consolidates-operational-kpi-library-for-mining-performance … Read More

Long-term mine plans don’t fail because of one bad assumption.

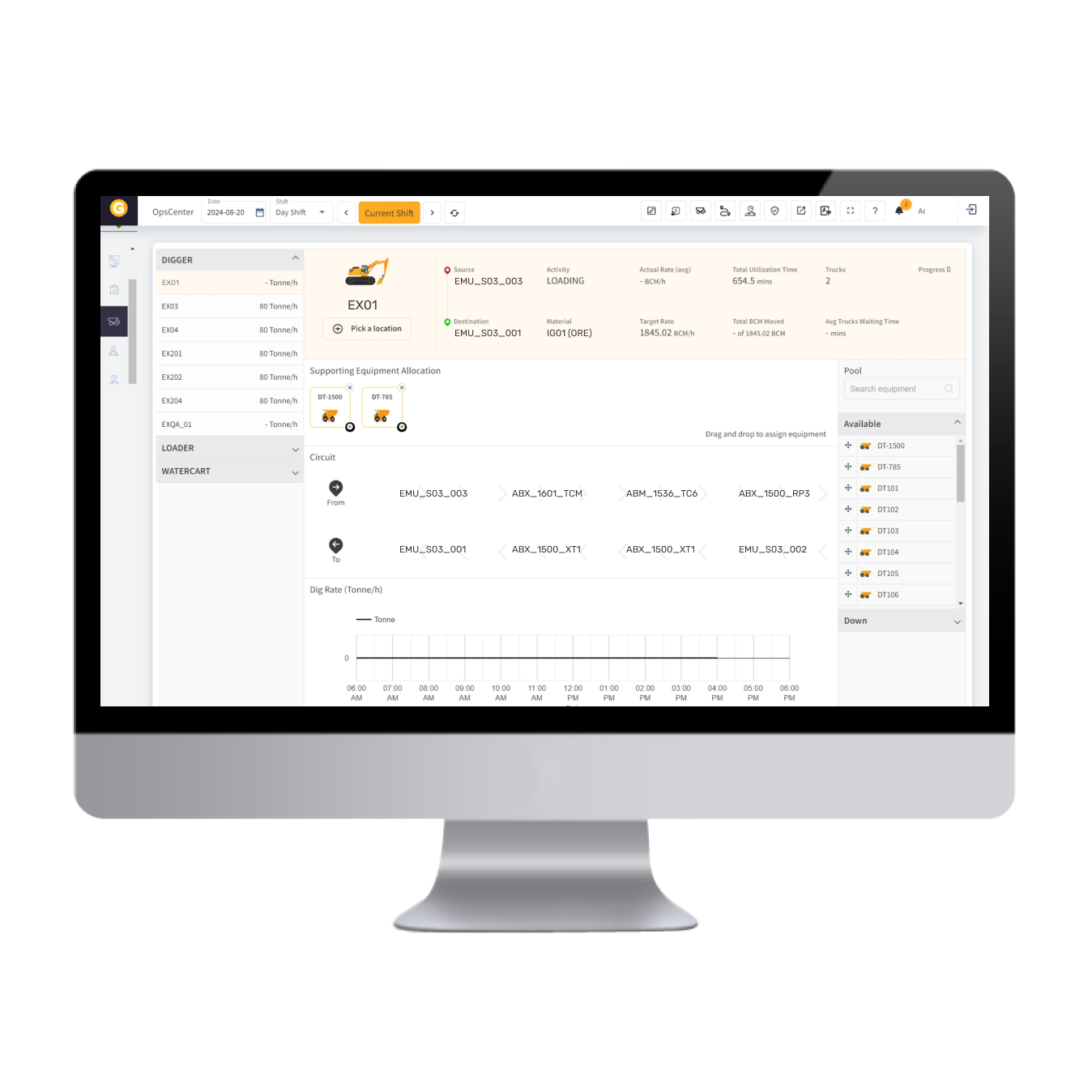

GroundHog FMS (Fleet Management System) is a state-of-the-art system designed to monitor and optimize the performance of a mine’s fleet, including primary production equipment like shovels, excavators, and haul trucks, as well as auxiliary equipment such as water trucks, graders, and more.

GroundHog FMS supports a wide range of equipment, including primary production fleet like shovels, excavators, and haul trucks, along with auxiliary equipment such as water trucks, graders, lighting towers, and over 40 other types of equipment commonly used at mine sites.

GroundHog FMS leverages advanced algorithms and technology infrastructures used by companies like Uber and Facebook. It is deployed on standard iPads and Android tablets, with intuitive interfaces designed for miners and dispatch operators.

Data collection in GroundHog FMS is automated through various sensors, on-board equipment telemetry, high-precision GPS units, and configurable geo-fences. The system stores data locally and transmits it to the GroundHog cloud using Peer-to-Peer, LoRa, WiFi, and Cellular networks.

Yes, GroundHog FMS uses Open APIs that easily integrate with third-party mining software, including SAP, ArcGIS, Mine Planning and Short Interval Control software, Drill and Blast, and others.

GroundHog FMS is part of the larger GroundHog Platform, which includes GroundHog Short Interval Control, Real-Time Location Tracking System, Peer-to-Peer Networking System, Telematics, IoT, Material Management, Digital Environmental, Health and Safety, and Learning Management Systems.

GroundHog’s intelligent Dispatch System uses real-time loading and haulage performance data, along with AI-based algorithms, to dynamically allocate haul trucks to shovels or front-wheel loaders. This maximizes tons hauled per shift, minimizes wait times, decreases traffic congestion, and increases overall haulage efficiency.