We’ll talk about how we can control ore dilution using High-Precision GPS and Geology & Ore Solutions to make mining more efficient, safer, and more sustainable. In this first part, we’ll give a general overview of the types of dilutions in open-pit mines and how dilution can reduce the value of the mine.

When we refer to ore dilution, we are talking about the waste material that is not separated from the ore during the mining operation and is consequently mined with the ore. This waste material gets mixed with the ore and is then sent to the processing plant, leading to an increase in tonnage and a decrease in mean grade relative to the initial plan. Dilution control is crucial for maintaining the economic viability and sustainability of mining projects.

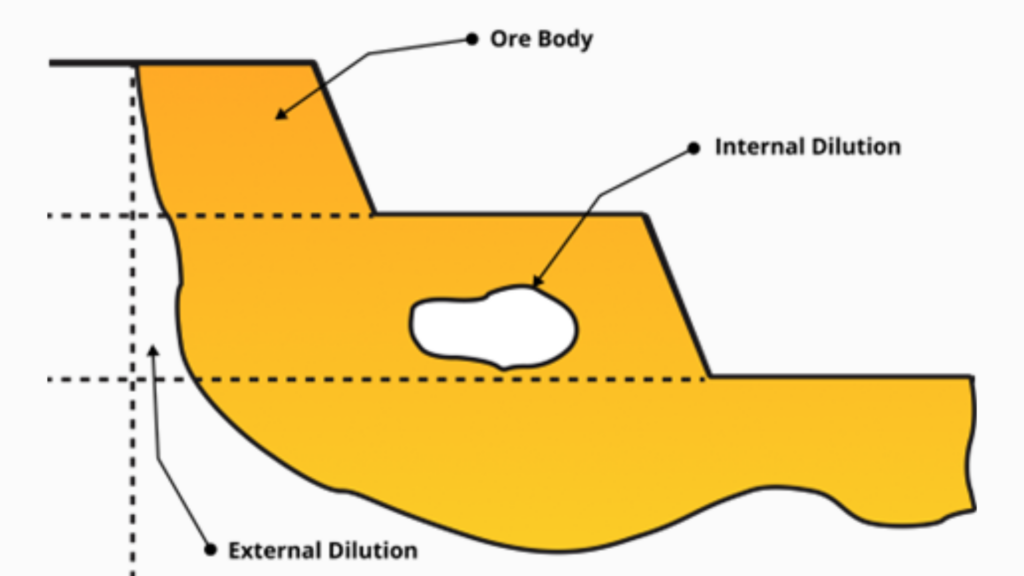

Internal and External Dilution

Dilution in mining operations can be internal and external. Referring to a mining block, ore dilution happens in two different areas. Figure 1 shows a mining block and bench depicting internal and external ore dilution. Internal dilution happens due to the presence of inter-burden within the orebody. External dilution happens at ore contact zone due to irregular shape of the ore body.

Internal Dilution

- Internal dilution occurs within a mining block in which pockets of waste are unable to be separated and are mined with the block.

- Low grade material surrounded by high grade material.

- Sometimes within a mining block there are waste inclusions or low-grade pockets of ore that cannot be separated and are inevitably mined with the mining block.

- Degrees of internal dilution can vary within various types of deposits; specifically lithological and grade distributions significantly influence the degree of dilution.

- Internal dilution is difficult if not impossible to avoid. The amount of internal dilution varies in different types of deposits. Lithology and grade distribution are important factors in internal dilution.

External dilution

- Refers to the waste outside of the orebody that is mined within the mining block.

- External dilution varies based on geology, shape of orebody, drilling and blasting techniques, scale of operation and equipment size.

- This is the type of dilution that can be controlled using proper equipment and mining practices. The following initiatives can be used to minimise external dilution:

- Defining the contact surfaces of the ore and waste

- Selection of the proper equipment to attain desired selectivity.

- Mining along the contact surfaces.

- Modelling the effects of unavoidable dilution.

Mine Value Diminutions Due to Dilution

One of the main consequences of dilution is the reduction of mill feed grade. Lower feed grade means less income. For marginal grade ore, dilution may reduce the grades to a degree that it becomes uneconomic to be processed, in other words dilution may turn an ore block to waste.

Thus, due to dilution:

- There will be material loss and overall reserve of the mine will decrease within a given pit.

- Energy and materials that are used in the processing plant to treat the waste portion of the feed are wasted. As a result, the mill unit operating cost increases directly by the amount of the dilution factor.

Method of Ore Dilution Control

Dilution control is essential to maximize ore recovery and minimize unnecessary waste material, which can significantly impact the overall profitability of the mine. By incorporating dilution control methodologies into their mining practices, companies can optimize their operations and achieve better outcomes in terms of ore extraction and resource utilization. Following are some strategies to effectively control dilution:

- Accurate Geological Modelling and Ore Body Knowledge: Improve the accuracy of geological models and orebody knowledge to precisely delineate the boundaries of the ore and waste zones.

- Precisely Demarcate Ore Contact Zone: Use of sub-blocks / partial percentage method during ore body modelling near the ore boundary zone.

- Optimized Mine Design: Develop detailed mine designs that consider the geological characteristics of the orebody. Implement bench heights and slope angles that minimize ore loss and waste material movement.

- Bench height selection based on Dip and Angle of Ore Body: Lower bench height for steeply dipping ore body.

- Mine Scheduling: Operation Sequencing based on Grade and Tonnage Target. Generate Grade Control Plan based on quality requirements.

- Drill and Blast Plan: Generate Drill and Blast Plan for Ore and Waste faces separately.

- Drill and Blast Techniques: Utilize precision drilling and blasting techniques to minimize damage to the orebody and surrounding rock, reducing dilution during the blasting process. Precise Drilling at Ore Contact Zone using HP GPS technology.

- Ore Contact Cleaning before Ore Face Blast: Develop ore faces by waste removal at contact zone. Ore contacts cleaning and remove all waste material from ore contact zone before the ore face blast.

- Proper Blasting Design: Design the blast patterns to avoid excessive fracturing and over-break, thereby minimizing dilution caused by blasting.

- Fragmentation Analysis: Conduct regular fragmentation analysis to assess the effectiveness of blasting and adjust techniques as needed to reduce dilution.

- Effective Grade Control: Implement effective grade control procedures to accurately determine the grade of the ore being mined, reducing the risk of dilution due to the blending of high- and low-grade materials.

- Update Block Model based on Blast hole sample analysis: Analyse drill cuttings sample and update Block Model on regular basis.

- Equipment Selection and Operation: Use appropriate mining equipment that can selectively mine the ore without unnecessary dilution.

- Real-Time Ore Control: Implement real-time ore control practices using on-board technology and data analytics to guide mining activities precisely. Use of HP GPS technology for Loading Operations.

- Proper Material Handling: Employ efficient material handling and ore transport methods to minimize ore loss and waste.

- Use of mis-haul alert system for potential wrong location dumping: Mis-haul alerts for the trucks diverted from designated route eliminate the chances of wrong location dumping.

- Proper Stockpile Management and Blend Management: Manage stockpile for different grade of ore and transfer ore material to and from the designated stockpile based on the quality requirement.

- Training and Supervision: Ensure that operators and mining personnel receive adequate training and supervision to avoid dilution due to human error.

- Geotechnical Stability: Maintain geotechnical stability to prevent unwanted movement of ore and waste material.

- Validation and Reconciliation: Regularly validate production results against mine plans to identify areas of excessive dilution and take corrective actions.

- Monitoring and Reporting: Establish comprehensive monitoring and reporting systems to track dilution levels and identify potential areas for improvement.

- Continuous Improvement: Foster a culture of continuous improvement within the mining operation to proactively address dilution-related challenges.

By adopting these strategies and continuously optimizing mining practices, mining operations can effectively control internal and external dilution, leading to improved ore recovery rates and increased profitability.

In conclusion, controlling ore dilution is vital for improving mining efficiency and profitability. Both internal and external dilution reduce mill feed grades and increase costs. By using strategies like accurate geological modeling, precision blasting, real-time ore control, and optimized mine design, dilution can be minimized. Continuous monitoring and improvements ensure better resource use and sustained profitability.