Introduction: The Role of Pre-Shift Inspections in Mining

Pre-shift inspections are integral to ensuring the safety, reliability, and efficiency of mining operations. These inspections verify that machinery and equipment are in working order, and they help identify issues before production begins, minimizing risk and reducing the likelihood of unexpected breakdowns during critical hours.

Key Steps in Pre-Shift Inspections

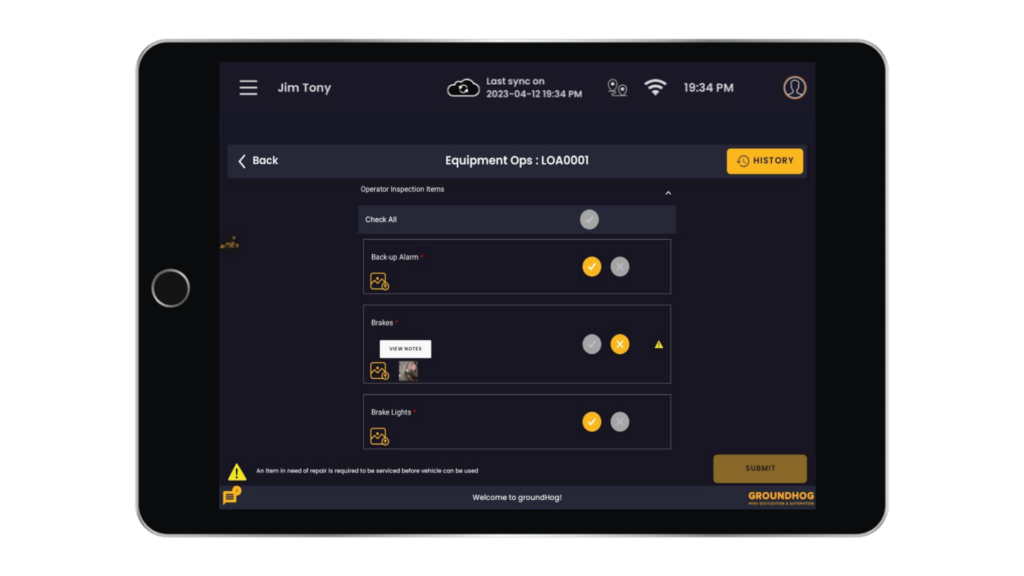

Ensuring Equipment Functionality

Effective pre-shift inspections check equipment for wear, lubrication, fuel levels, and other key indicators of readiness. For instance, a hydraulic excavator’s fluid levels, pressure gauges, and hydraulic hoses are inspected to ensure no leaks or faults. By dealing with such issues early, maintenance teams can resolve minor problems before they escalate into full-scale failures.

Identification of Maintenance Needs

Regular inspections help identify early maintenance needs that could impact productivity. For instance, a minor issue with a Dozer identified during an inspection can be addressed immediately, avoiding a breakdown that would halt operations for hours. Time based preventative maintenance schedule can be prepared and implemented to minimize sudden breakdown of equipment.

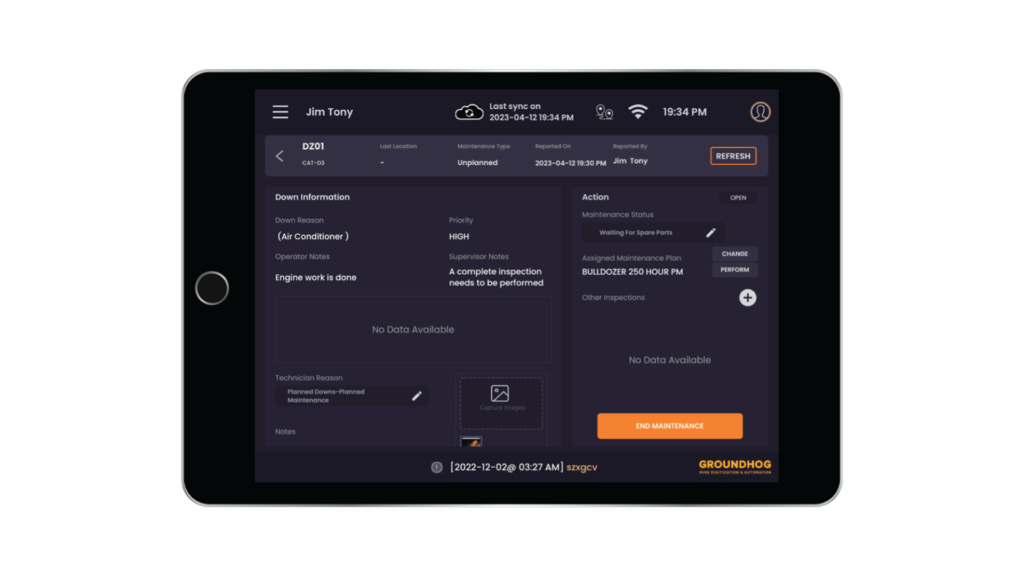

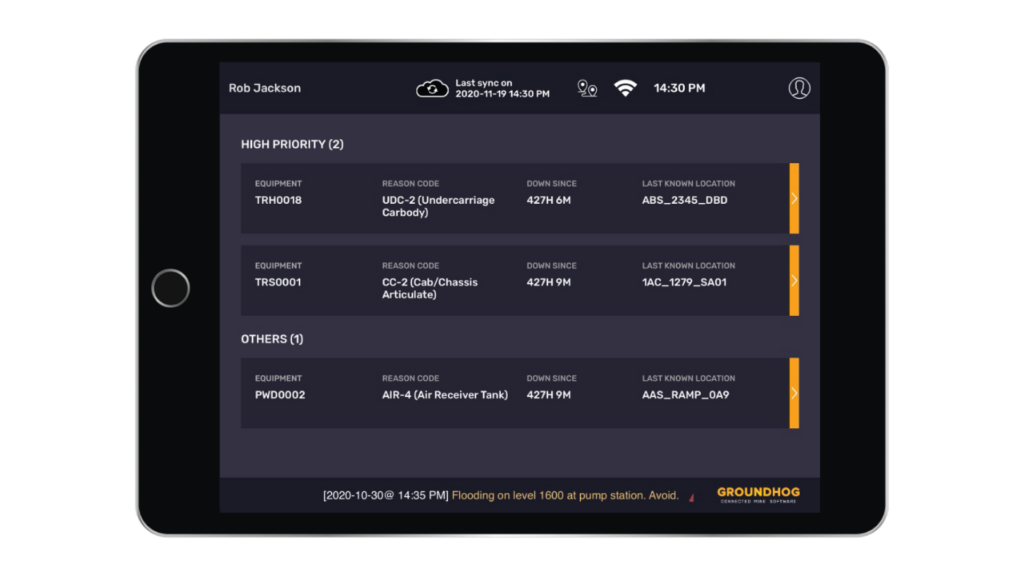

Real-Time Alerting on Failures

When pre-shift inspections uncover issues, the GroundHog FMS system automatically alerts maintenance personnel, ensuring rapid response. For any equipment breakdown, GroundHog FMS sends an alert to the maintenance team with location of equipment, down reason code and relevant images so that maintenance team can plan maintenance activity effectively. It improves response time, reduces breakdown time of equipment and reduces Mean Time Between Failure (MTBF). Equipment reliability not only improves productivity but also avoids potentially dangerous operations due to accidental breakdown.

Conclusion: Enhancing Reliability with Pre-Shift Inspections

Pre-shift inspections keep machinery and personnel safe, minimize unexpected delays, and ensure a reliable start to every shift. This preventative measure is essential for high-functioning and safe mining operations.