The Art of Long-Term Mine Planning

Long-term mine plans don’t fail because of one bad assumption.

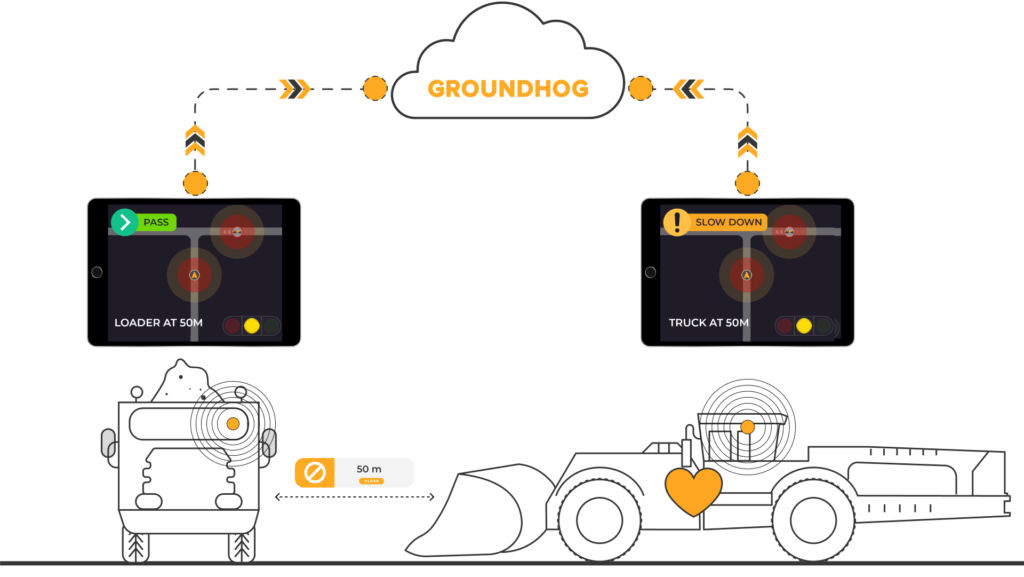

GroundHog Proximity Detection Solutions combine third-party proximity beacons with the GroundHog FMS system. These components work together to deliver instant alerts when equipment and personnel are in close proximity, enhancing safety across your operation.

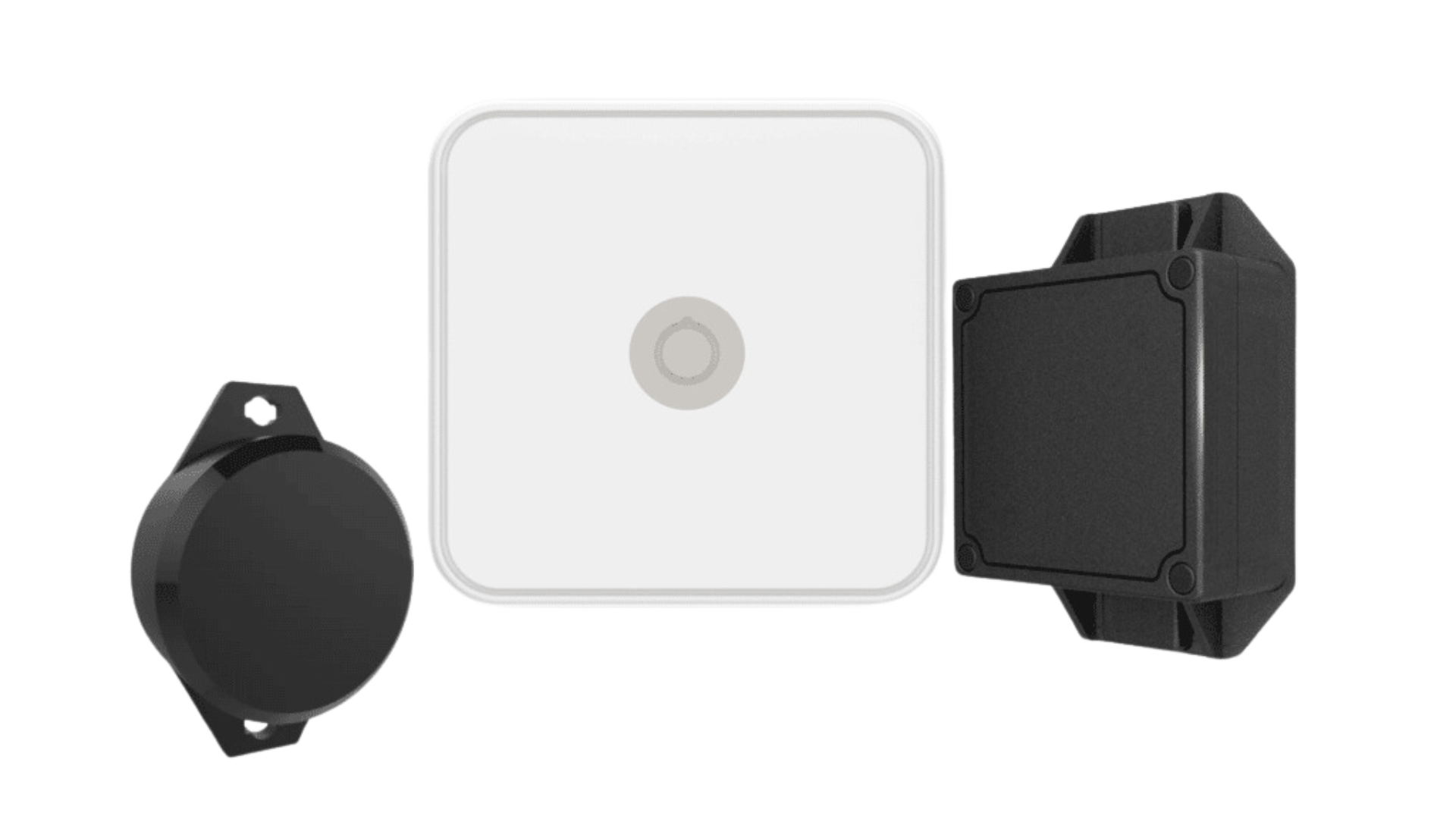

No need for external power sources or additional equipment. Simply attach it to your equipment, configure it, and it’s ready to go

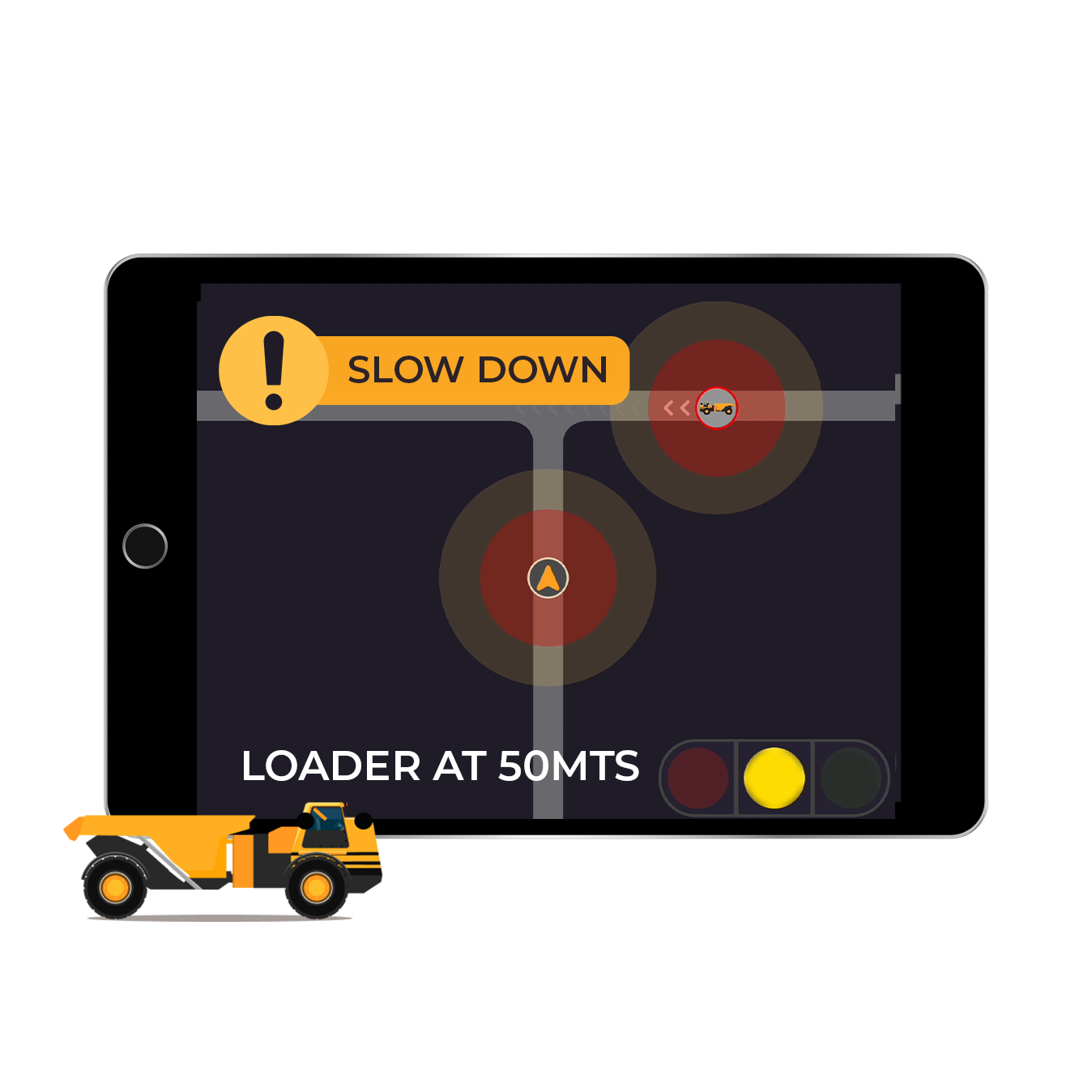

The standard off-the-shelf beacon is installed on every piece of equipment, in key environments, or carried by each personnel. It can be easily placed in a vest or simply carried in a pocket. Whenever the beacon enters the danger zone near any equipment, the GroundHog application on a tablet immediately detects it and triggers a visual and audio alarm.

Ensure the driver is always aware of potential hazards.

GroundHog CAS system’s real-time alerts, configurable detection range, and data logging ensure that operators are promptly informed of potential hazards, leading to improved safety and operational efficiency.

Deliver instant alerts when equipment and personnel are in close proximity

Long-term mine plans don’t fail because of one bad assumption.

This technical guide brings together the Digital and Technology KPIs

This technical guide brings together the Shared Operational KPIs that

Proximity detection is a safety technology that uses sensors to detect the presence and movement of personnel, equipment, or vehicles in relation to each other to prevent collisions and enhance situational awareness.

Collision alerts are warnings generated by detection systems when there is a risk of collision between mining equipment, vehicles, or personnel, helping to prevent accidents and improve safety.

Proximity detection systems use various sensors, such as radar, ultrasonic, or infrared, to monitor the distance between objects. When an object comes too close, the system triggers an alert to prevent potential collisions.

Common sensors include radar, ultrasonic, infrared, and GPS. These sensors help detect the proximity of objects and provide real-time data to the monitoring system.

Collision alerts provide real-time warnings to operators and personnel, allowing them to take corrective actions to avoid accidents. This helps prevent injuries, equipment damage, and operational disruptions.

Yes, many proximity detection systems can be integrated with existing mining equipment and vehicle systems, providing enhanced safety without requiring complete equipment overhauls.

Proximity detection data is used to monitor and analyze the movement and interactions of equipment and personnel, helping to identify potential hazards and improve safety protocols.

Benefits include enhanced safety, reduced risk of accidents, improved operational efficiency, and better compliance with safety regulations.

Regular calibration and maintenance are essential to ensure accurate and reliable performance. The frequency of maintenance depends on the system and operational conditions but typically involves periodic checks and adjustments.

Challenges include the initial cost of installation, integration with existing systems, potential sensor interference, and the need for ongoing maintenance and calibration.

They improve safety, reduce accident-related downtime and costs, enhance operational efficiency, and contribute to a safer working environment for personnel.