Downtime and Its Costs in Mining

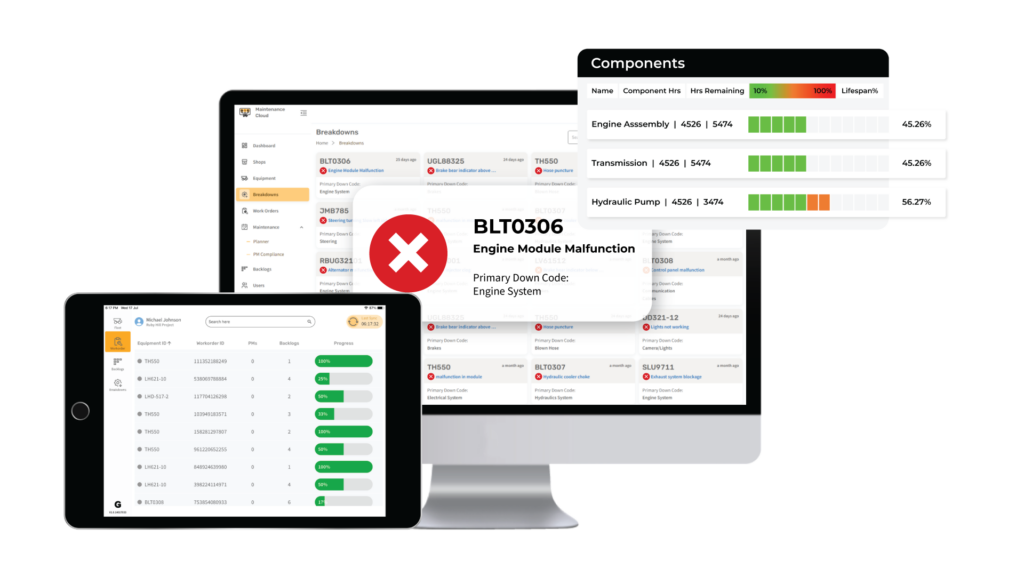

In the mining industry, equipment downtime translates directly to lost production and revenue. Predictive maintenance uses real-time data and predictive analytics to foresee equipment failures before they happen, preventing unplanned downtime and improving operational reliability. GroundHog FMS enables predictive maintenance, reducing the need for costly emergency repairs.

How Predictive Maintenance Reduces Downtime

Real-Time Condition Monitoring

Predictive maintenance systems monitor equipment in real time, tracking indicators like temperature, vibration, and oil quality. For instance, a rise in engine temperature on a haul truck could suggest a potential failure. With predictive maintenance, operators are alerted to such anomalies, allowing maintenance teams to address issues before they cause downtime.

Scheduling Maintenance During Non-Productive Hours

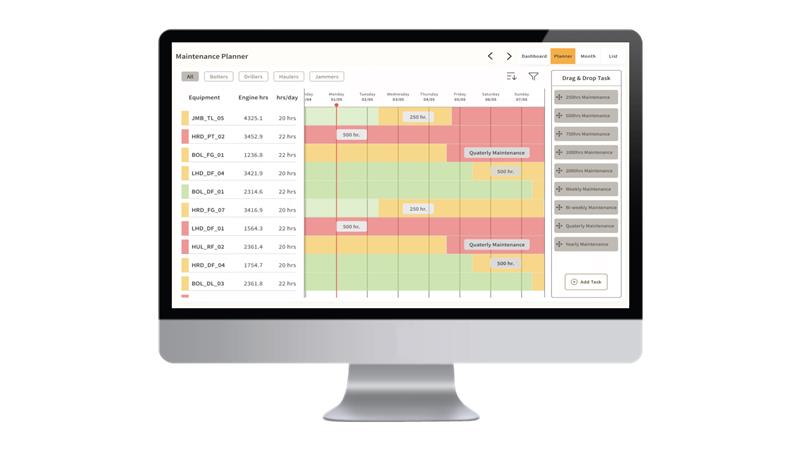

Predictive maintenance helps teams schedule repairs during non-peak hours. For example, if a drill rig is showing early signs of wear, maintenance can be planned during shift changes or idle time rather than interrupting production. This approach minimizes disruptions and keeps critical equipment in optimal condition.

Reducing Unexpected Equipment Failures

3.With data-driven insights, teams can identify patterns and predict when parts will need replacement. For example, wear-and-tear data from excavators may indicate that the hydraulic system needs servicing after a certain number of cycles. By replacing parts proactively, companies avoid the disruptions and expenses associated with emergency repairs. It also helps in optimized inventory management.

Conclusion: A Proactive Approach to Maintenance

Predictive maintenance minimizes unplanned downtime, enhances equipment life, and lowers operational costs. With GroundHog FMS and CMMS, mining companies can move from reactive to proactive maintenance, ensuring smooth, uninterrupted production.