Digital Mining and the Path to Green Mining

Green mining begins with operational discipline. In this eBook, we

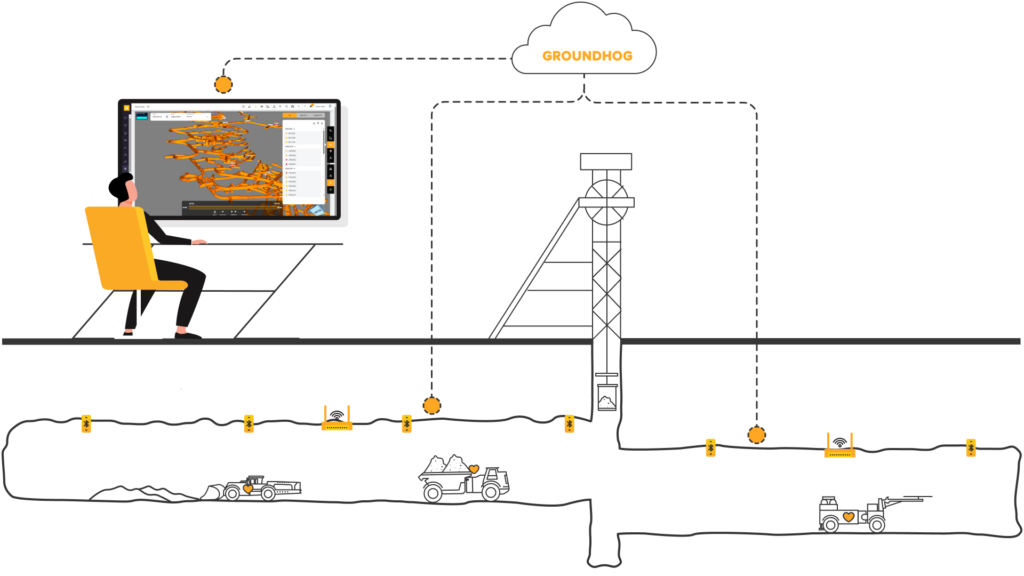

GroundHog uses state-of-the-art RTLS beacon technology with a revolutionary 3-D visualization engine to track and locate all personnel and equipment underground.

Track and monitor equipment location underground in real-time using a detailed 3D map

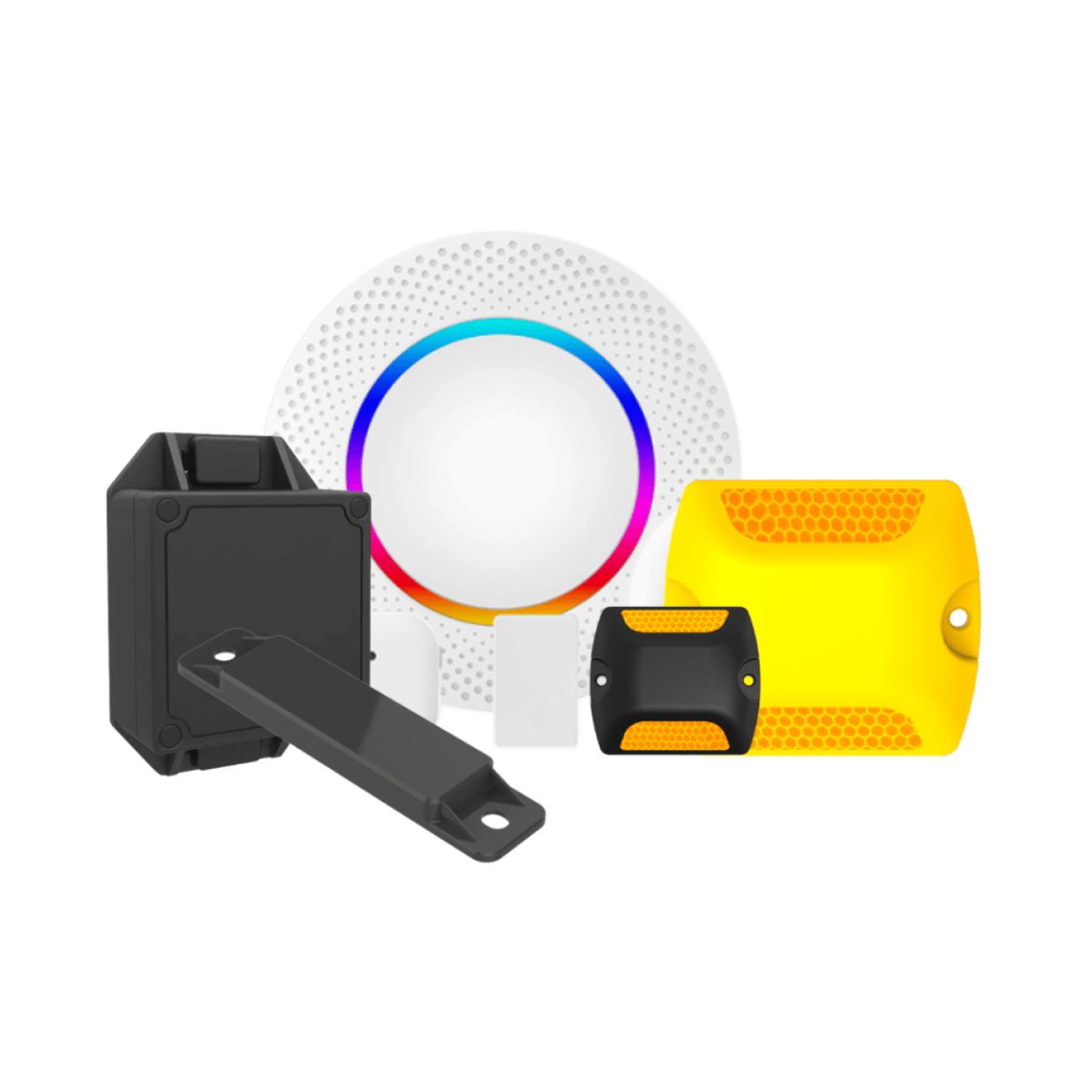

Cost-effective, off-the-shelf, IP-68 rated hardware with 10 year battery life

GroundHog uses off-the-shelf hardware that mines can deploy at ramps, headings, stopes, crosscuts, ore-passes, muck bays, grizzlies, and wherever else you may work underground to track all equipment and personnel. Also, attach to equipment as and when necessary.

The RTLS engine runs on a standard WiFi infrastructure without requiring a separate network.

Automate trip tracking, get real-time traffic prioritization and dynamic haulage route optimization underground

The GroundHog RTLS system improves both accuracy in equipment monitoring and overall traffic management. By automating trip counts and providing precise real-time location data, the system enhances fleet tracking and resource allocation.

Green mining begins with operational discipline. In this eBook, we

Consolidates-operational-kpi-library-for-mining-performance … Read More

Long-term mine plans don’t fail because of one bad assumption.

Use case #1: Miner Safety

The essential use case is safety. For example, when an incident requires all underground personnel to evacuate, mines can rely on RTLS to ensure all personnel have safely moved to a mine rescue chamber or have come to the surface.

A central control room can also monitor lone workers and keep track of the last known location of a miner. This level of awareness helps during mine rescue operations so the rescue team can narrow the search and rescue area.

RTLS allows for quick and accurate responses to any incidents that may occur.

The right technology also allows detecting if a miner is down possible. I will describe how to do so using BLE beacons.

Use case #2: Locating equipment underground

Most mine operations monitor Equipment Availability and Utilization using a Time Utilization Model (TUM). When a mine seriously looks into increasing efficiency, they can pull two levers almost immediately: identify operating delays and standbys. Underground equipment sits on standby during shift change, so continuous improvement managers must look for ways to get butts-in-seats faster, thereby reducing standby times.

At shift change, locating equipment underground can often take over 20 minutes or more – especially if it is not the primary load-haul equipment. Using RTLS, a miner can visually identify the exact location of a piece of equipment at a shift change line-up meeting, thereby increasing overall effective shift time to more than 30 minutes per day.

Using simple back-of-the-envelope math: if a mine produces 2000 tons per day, assuming 21 hours of effective shift length, everything else being equal, you could achieve an additional 50 tons per day (approximately 2050 tons – or two additional truck loads). Of course, for many, load-haul equipment utilization is effective with concepts like hot-shift changes, etc. But unlocking an additional 30 minutes per shift across your workforce can improve overall productivity – think development, production, construction, electrical and mechanical ops.

Use case #3: Automated trip counting, material inventory and movement underground.

Automated counting of trips to surface is the most straightforward use case to implement using RTLS hardware. For example, in a portal access mine, installing tracking beacons and readers on the equipment and at the portal entrance, you can count the number of times a haul truck went underground and returned to surface. The limitation is that you can’t tell whether the truck is loaded. Adding a payload sensor to track actual trips with tonnes solves this problem.

Many of our customers also install sensors on loading units and the ribs of ramps, headings, muck bays, and ore pass. So when a haul truck visits a particular loader (LHD / Bogger / Scoop depending on where you are reading this article), you can assume that it got loaded, along with the location, and the grade of material, so geologists can also track the material inventory and material movement underground.

A Real-Time Location Tracking solution uses three main components in underground mines:

RTLS Beacons / Tags

There are three main types of beacons (also generally called tags for gen one and gen two tech) – Time of Flight (ToF), WiFi, and Bluetooth BLE beacons. I will discuss the pros and cons of these technologies in a separate post. However, know that ToF beacons used by some solution providers use generation one technology. WiFi beacons used by some providers use generation two technology. GroundHog’s RTLS Bluetooth beacons use generation three technology. You should know that companies using Gen 1 and Gen 2 technologies can continually rebuild their systems to use Generation 3 BLE Devices.

These tags are typically installed on equipment or encapsulated in the miner’s cap lamps. Each tag has a unique ID associated with a miner or equipment.

RTLS Readers

As discussed earlier, readers installed throughout the mine detect the tag when it passes by the reader.

While the underlying technology is slightly different, they all achieve the same purpose.

Central Monitoring System, Visualization Tools and 3D Mine Maps

A central monitoring system displays the location information on a map, allowing for real-time monitoring of the movements of personnel and equipment throughout the mine.

The final piece of the RTLS puzzle is the visualization tool. Modern visualization systems such as GroundHog import 3D mine maps from commonly used survey software in DXF or DWG files. The mine IT team configures the locations of the readers on the 3D mine map within the GroundHog RTLS system as easy as pointing to a location on the 3D mine map and assigning the beacon ID and the location’s name.

For example, when haul-truck TRK007’s beacon passes by the muck bay MKB_1600_CT2, the GroundHog RTLS solution visualizes that TRK0097 is at MKB_1600_CT2. As a result, Mine Control/Dispatch, Superintendents, Shift Bosses, and miners can now keep track of all the equipment and personnel underground.

As we’ve outlined here, there are several benefits to using real-time location tracking in underground mining operations. The key benefits include increased safety, improved efficiency, and reduced costs.

Over the next 5-10 years, most underground mines will deploy some form of RTLS – primarily for safety use cases, with efficiency and traffic management as add-on benefits.