Caterpillar Telemetry Data Extraction: A Powerful Technical Guide – Part 1

Mastering Caterpillar Telemetry: A Step-by-Step Guide to Efficient Data Extraction

GroundHog Telematics delivers advanced analytics, helping mines track fuel use, engine hours, fault codes, and operator actions, to reduce downtime and improve equipment health.

Get Operational Data Directly from Equipment Telematics

Operators or technicians manually enter engine hours. GroundHog Telematics automates this, significantly reducing errors and improving accuracy. See canbox.io for more information on GroundHog Telematics system.

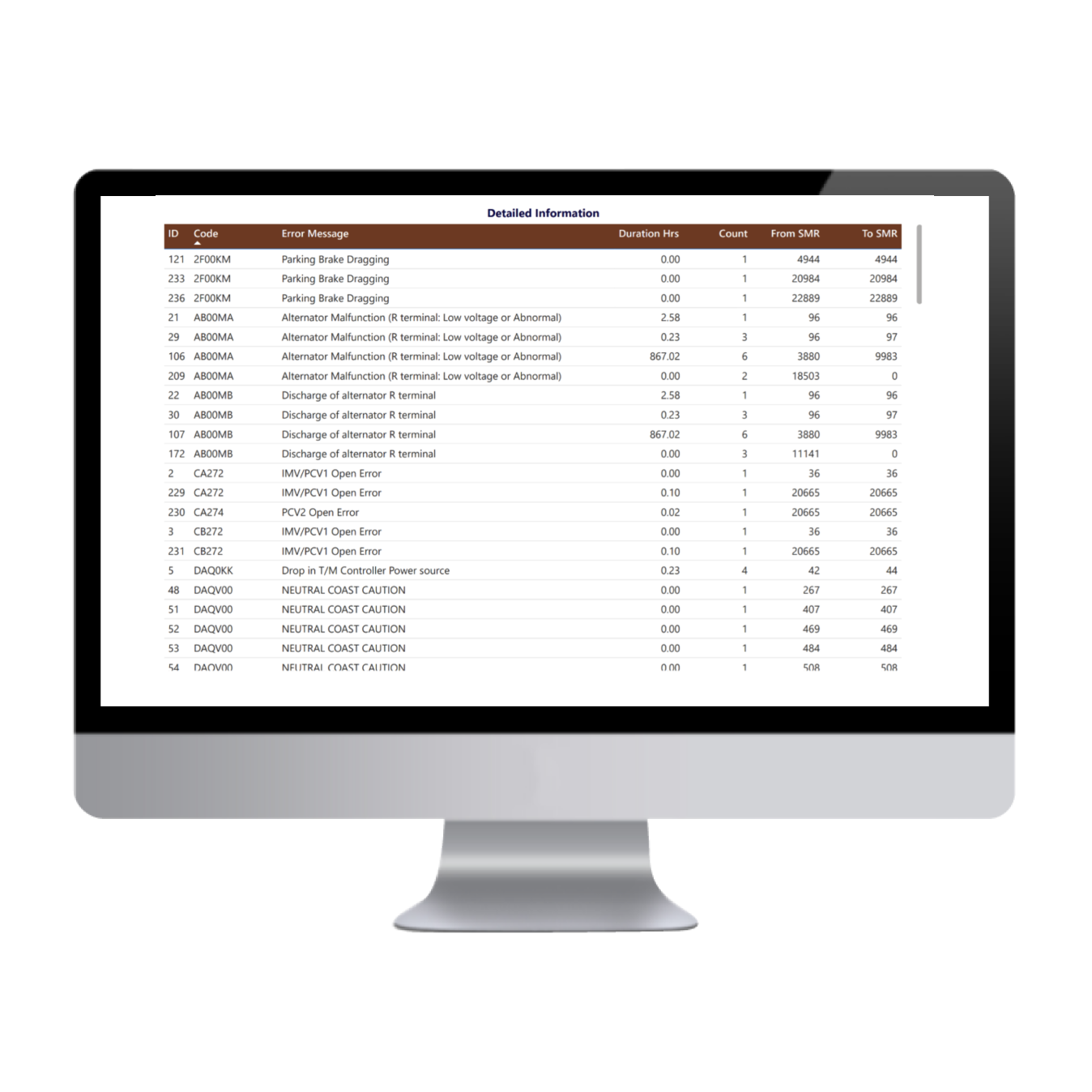

Down Reason Codes and Fault Codes Help Identify Issues Accurately

GroundHog Telematics enables quick diagnosis and problem-solving, minimizing delays and ensuring smooth, uninterrupted operations. See canbox.io for more information on GroundHog Telematics system.

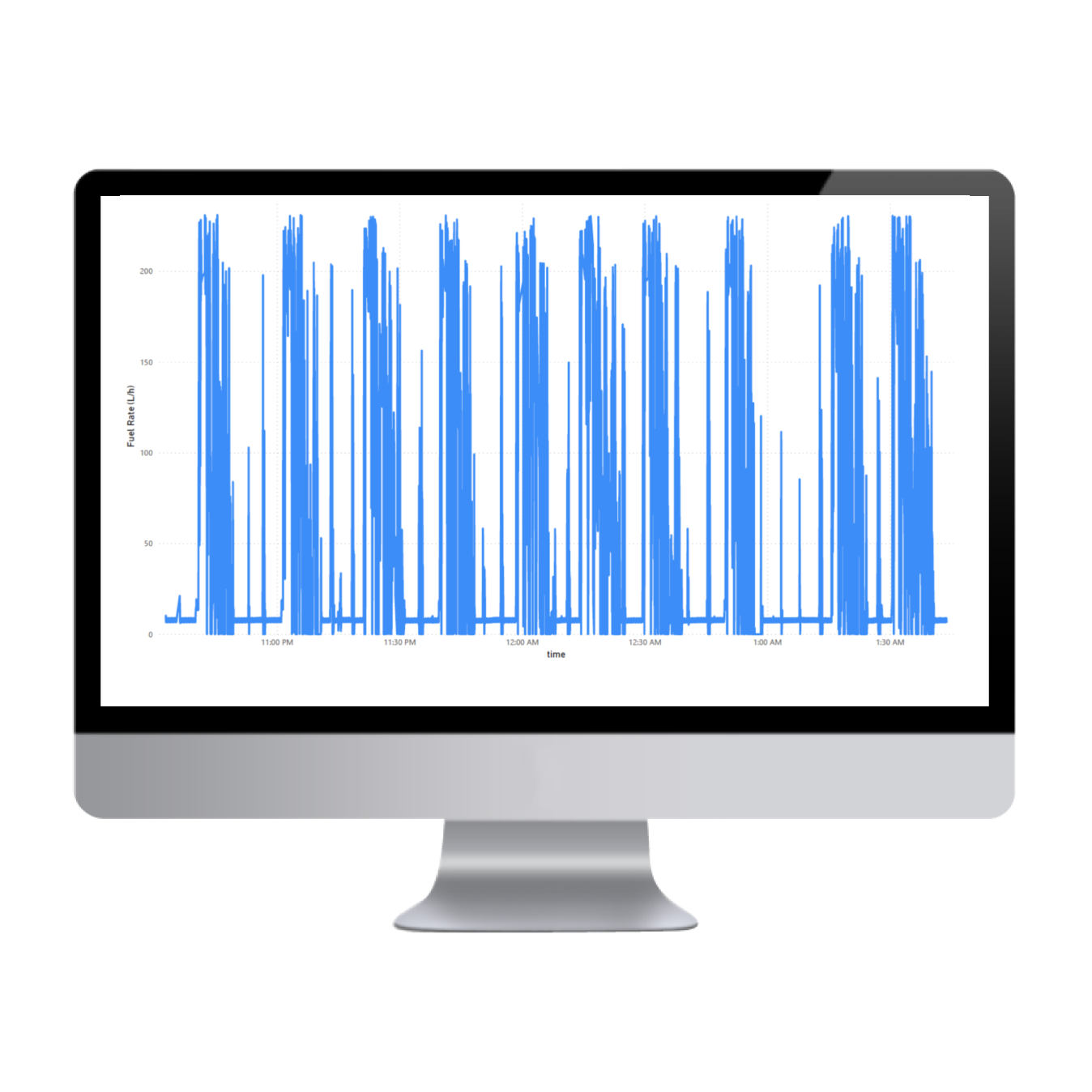

Analyze Fuel Usage Patterns to Identify Inefficiencies and Optimize Fuel Management.

Track Payload Data in Real-time to Ensure Accurate Load Measurement and Optimize Operations.

GroundHog Telematics offers advanced payload tracking features, providing real-time insights into load measurements. For more details on the GroundHog Telematics system, visit canbox.io.

Turn Data into Action with Operator Behavior Analytics

Discover How GroundHog Short Interval Control makes Shift Planning Easy!

Read Related Blogs and Access Useful Links

Mastering Caterpillar Telemetry: A Step-by-Step Guide to Efficient Data Extraction

Telematics in mining refers to the use of integrated communication and monitoring systems that collect and transmit data from mining equipment and operations. This data includes machine performance, location, utilization, and diagnostic information, which can be used to optimize operations, improve safety, and reduce costs.

Telematics improves mining operations by providing real-time data on equipment performance, fuel consumption, and maintenance needs. This helps operators make informed decisions, reduce downtime, increase equipment lifespan, and enhance overall operational efficiency.

Telematics systems can collect a variety of data, including:

Telematics enhances safety by monitoring equipment conditions and alerting operators to potential issues before they become serious problems. It can also track personnel locations and ensure compliance with safety protocols, improving emergency response times and reducing accident risks.

Yes, many telematics systems are designed to be compatible with a wide range of mining equipment. They can often be retrofitted to older machines or integrated with newer equipment to provide comprehensive monitoring and data collection.

Telematics offers several benefits for fleet management, including:

Telematics systems typically use encrypted communication channels to ensure the security of data transmitted from equipment to monitoring platforms. Additionally, many systems have built-in security features to protect data from unauthorized access and breaches.

When selecting a telematics system for mining, consider features such as:

The costs of telematics systems can vary based on factors such as the size of your fleet, the complexity of the system, and the features included. Typically, costs include the initial hardware and installation fees, as well as ongoing subscription or data service charges. It’s important to consider the potential cost savings and operational improvements when evaluating the investment.