Maximizing Blending Compliance: GroundHog Launches Advanced ROM Loader Software

California, 27 August 2024 —GroundHog, a leader in digital solutions

GroundHog’s Underground Fleet Management System delivers complete mine management from the production face to the central office, continuously monitoring all underground activities to enhance face and equipment utilization.

GroundHog FMS integrates with GroundHog SIC to Optimize Activity Sequencing in Real-Time.

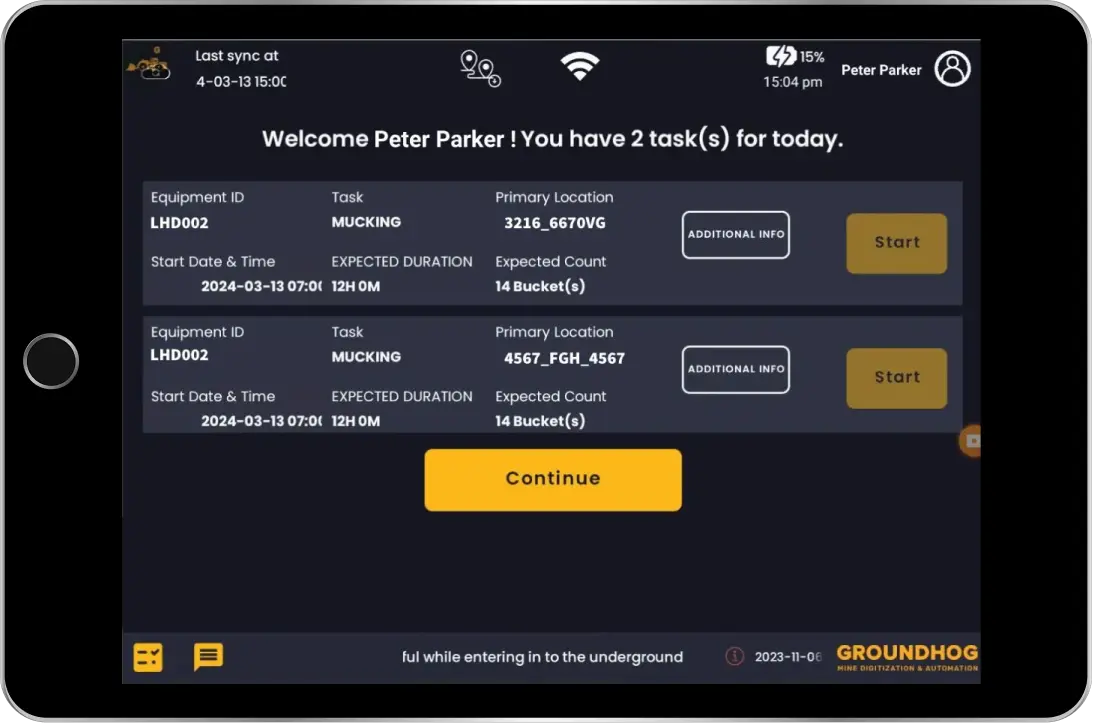

GroundHog SIC automatically sequences activities by considering equipment, personnel, activity durations, and tramming times for optimal utilization.

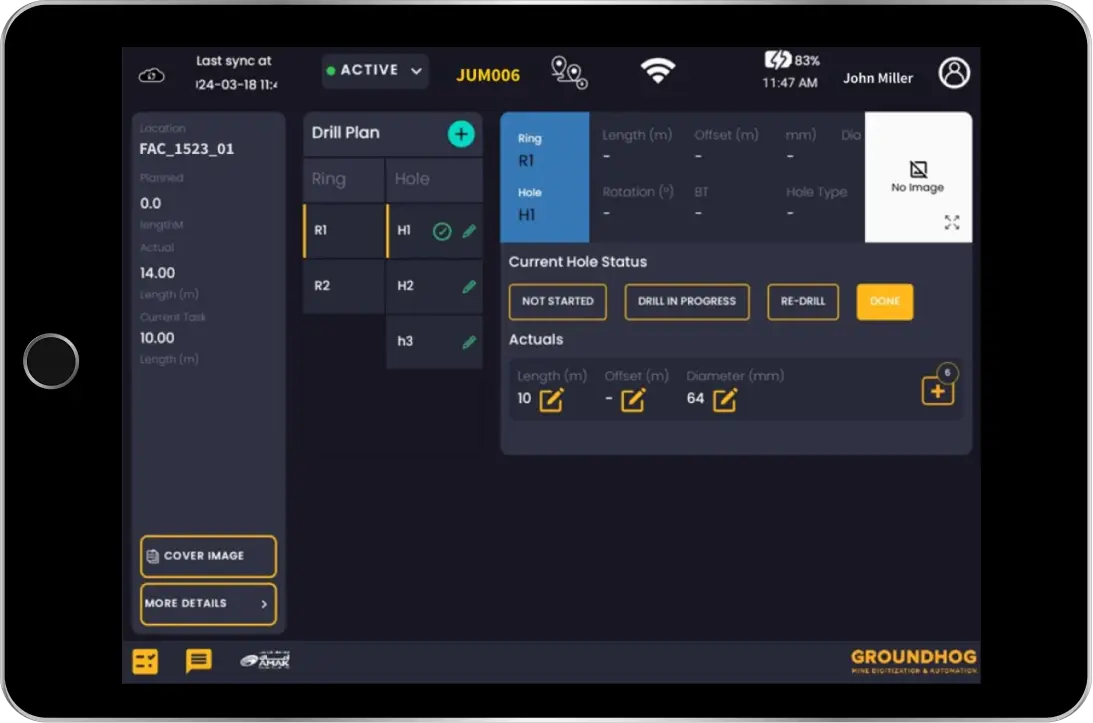

Real-Time Recording of Production Data for Drilling, Blasting, Mucking, Loading, and Hauling.

Many mines use paper for data, causing errors. Digital capture improves accuracy, with GroundHog Peer-to-Peer for near real-time data when Wi-Fi is unavailable.

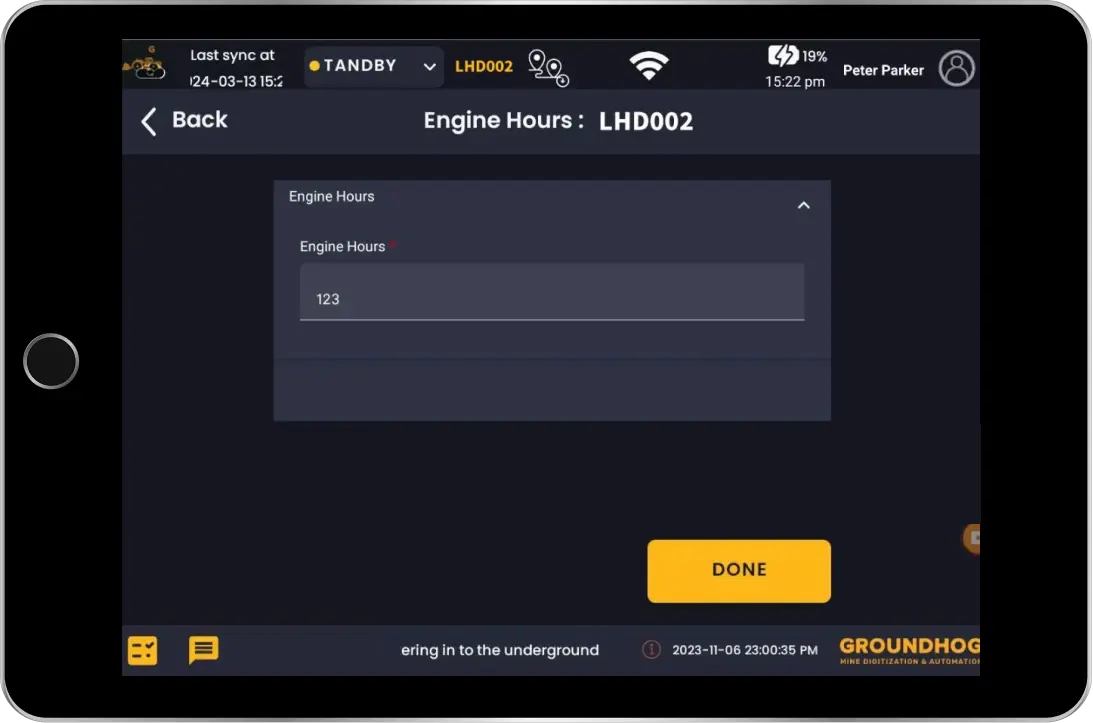

Automate Machine and Payload Data Capture for Improved Asset Health and Tonnage Tracking.

GroundHog Fleet Management System integrates with GroundHog ‘s on-board Telemetry and Payload Unit via Wi-FI to capture machine and payload data automatically and monitor asset health. Integration with weighbridge systems also provides autoamted payload data

Keep Track on Inventory Levels, Material Movement from Face to Mill Feed.

Our Mine Fleet management system helps with material management so that Production Planners can prioritize which locations to haul out of to meet the mill’s blend requirements.

Real-Time Monitoring, Automated Work Orders, and Performance Metrics for Optimal Efficiency

GroundHog FMS system tracks equipment metrics and data to optimize performance and increase uptime. Mine managers and maintenance teams monitor these metrics constantly via Power BI dashboards.

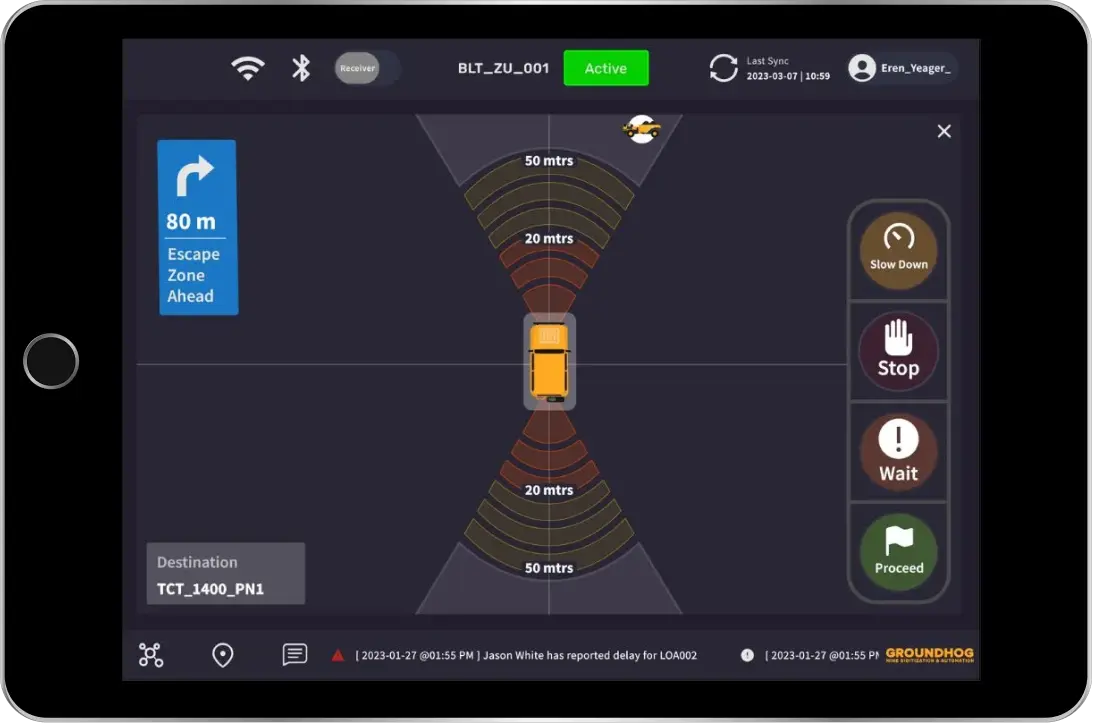

Real-time Location Tracking, Proximity Detection and Collision Alerts

Our advanced systems enhance situational awareness and operator safety by integrating real-time location tracking, collision prevention, and traffic management.

Digitize data capture via phone, tablet, or sensors to boost accuracy and efficiency in every task!

Read Related Blogs and Access Useful Links

California, 27 August 2024 —GroundHog, a leader in digital solutions

Battery electric vehicles (BEVs) have the potential to transform the

Mines have been leveraging fleet management systems (FMS) and telemetry

GroundHog FMS stands out with its real-time data capture, AI-based Short Interval Control (SIC) scheduler, and the ability to run on off-the-shelf devices like iPads and Android tablets. It also supports advanced analytics and detailed reporting.

Yes, GroundHog FMS is highly configurable and can be tailored to suit specific mining methods such as room and pillar, block caving, or longwall mining. The system can be configured to meet the unique requirements of each method, ensuring optimal performance and efficiency.

GroundHog FMS supports multiple languages, allowing operators and supervisors to use the system in their preferred language. This feature helps in reducing communication barriers and ensures that all users can interact with the system effectively.

GroundHog FMS is designed to scale with your operations. The system can be easily upgraded with additional modules or expanded to accommodate more equipment and users. The cloud-based architecture allows for seamless scaling without significant downtime or disruption to operations.

GroundHog FMS tracks fuel consumption and equipment efficiency in real-time via GroundHog Telemetry integration and fuel sensor integration.

GroundHog FMS offers a wide range of customizable reports, including equipment utilization, production rates, fuel consumption, maintenance schedules, and safety incidents. These reports can be generated in real-time and exported in various formats for analysis and decision-making.

GroundHog FMS automates the shift change process by generating end-of-shift logs and facilitating easy operator assignments. The system ensures operators are assigned to the right equipment based on their skills and availability, reducing downtime and increasing shift efficiency.

Yes, GroundHog FMS is designed to integrate seamlessly with a wide range of IoT devices and sensors. The system supports open APIs, allowing it to connect with existing hardware and software solutions, enabling a cohesive and comprehensive fleet management system.

GroundHog FMS is designed for minimal maintenance. Regular software updates are provided to ensure the system is up-to-date. The hardware used, such as tablets and sensors, may require periodic checks, but overall, the system is built for durability and long-term use in demanding mining environments.

GroundHog FMS provides real-time alerts and notifications in case of emergencies and provides detailed logs for post-incident analysis.

The return on investment (ROI) is typically realized through increased productivity, reduced operational costs, and enhanced equipment utilization. Mines often see significant improvements in cycle times, fuel efficiency, and overall production rates, leading to substantial cost savings.

GroundHog FMS provides detailed reporting and audit trails that help mines comply with local and international regulations. The system’s automated data capture ensures accurate and timely reporting, reducing the risk of non-compliance and associated penalties.

GroundHog FMS runs on standard off-the-shelf devices such as iPads, Android tablets, and smartphones. The system is compatible with various telemetry units and sensors, and the network infrastructure required includes WiFi, LoRa, or Peer-to-Peer networks.

GroundHog FMS includes built-in training modules and user-friendly interfaces that help new operators and technicians quickly learn how to use the system.

GroundHog FMS is built with open APIs, making it easy to integrate with your existing systems, including SAP, Vulcan, Deswik, and others. Our team works closely with you to ensure a seamless integration process, allowing for smooth data flow and interoperability.

GroundHog FMS is designed with user-friendliness in mind, featuring intuitive interfaces for both operators and supervisors. While the system is straightforward to use, implementation may involve challenges such as data migration and user adaptation. Our team provides full support during the implementation phase to overcome these challenges.