This white paper explores how a major West African gold mine uncovered the hidden costs of haulage inefficiency. Despite strict cost controls, the site was losing millions each year to fuel overconsumption. GroundHog’s Fleet Management System, powered by real-time GPS

GroundHog Open Pit FMS Dispatchers’ Handbook

Efficient haulage is critical to meeting production targets and controlling costs in open-pit mining. In this handbook, we outline how the GroundHog Open Pit Fleet Management System (FMS) equips dispatchers to optimize truck-shovel operations, reduce delays, and improve overall productivity.

Reshaping Mine Safety Training: Understanding MSHA-2025-0085

In the first half of 2025, MSHA issued over 43,000 citations — and nearly 20% were classified as “Significant & Substantial.” But here’s the kicker: the most common MSHA violations weren’t obscure or technical. They were for basic safety failures like poor housekeeping, missing machine guards, and unsafe access. This blog breaks down the top MSHA violations in metal/nonmetal mines and explains how getting the fundamentals right can drastically reduce citations and keep your team safe. … Read More

Improving Operational Efficiency at Mines French.

Dans cet eBook, nous explorons comment l’industrie minière a évolué avec l’essor de la numérisation et de l’automatisation, transformant les enjeux liés à l’efficacité des équipements. Pour relever ces défis et réduire les coûts de production, les responsables de mines

Improving Operational Efficiency at Mines – Turkish.

Bu eKitapta, madencilik sektörünün dijitalleşme ve otomasyonun yükselişiyle nasıl dönüştüğünü, ekipman verimliliğine dair endişelerin nasıl şekil değiştirdiğini ele alıyoruz. Bu zorluklarla başa çıkmak ve üretim maliyetlerini düşürmek isteyen maden yöneticileri, ekipman performansını artıracak yenilikçi çözümler arıyor. Bu hedefte kilit bir

Elevating Maintenance Operations Turkish

Bu e-Kitapta, bakım departmanınızı kuruluşunuz için stratejik bir varlığa dönüştürerek bakım operasyonlarınızı nasıl geliştireceğinizi öğreneceksiniz. Bakımın Stratejik Rolü: Varlık güvenilirliğini sağlamak ve kurumsal başarıya ulaşmak için bakım ekiplerinin kritik önemini anlayın. Modern bakım uygulamalarının, sadece rutin onarımların ötesine geçerek daha

Ore Dilution and Quality Control in Open Pit Mines Turkish

La dilution du minerai et le contrôle de la qualité sont des aspects essentiels de l’exploitation minière à ciel ouvert pour garantir une extraction efficace des ressources et maximiser la valeur économique du matériau extrait. L’intégration de solutions GPS haute

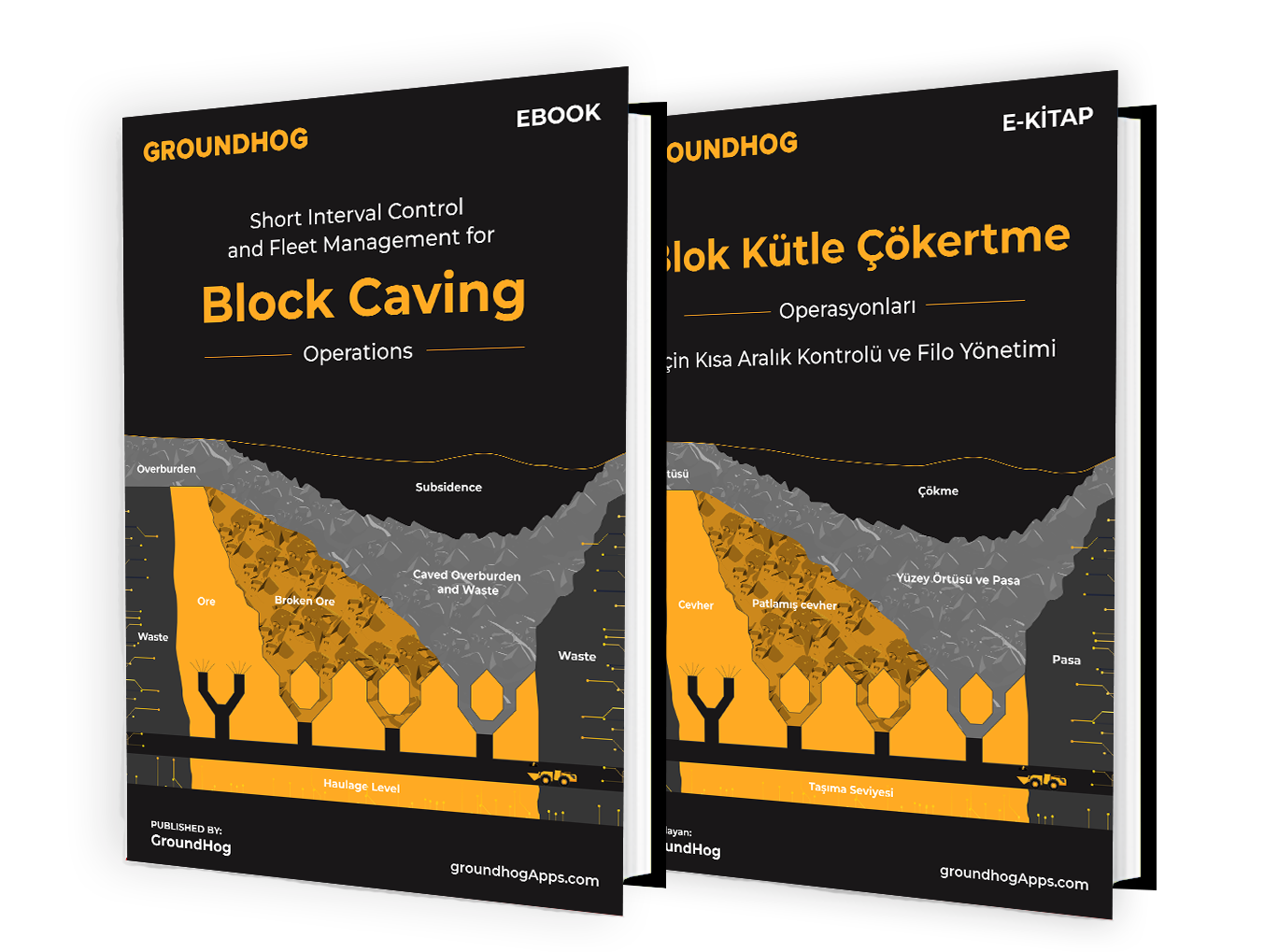

Short Interval Control and FMS for Block Caving Operations Turkish

Block caving, yerçekimi etkisini kullanarak büyük ve düşük tenörlü cevher yataklarını çıkarmaya olanak tanıyan, maliyet etkin bir madencilik yöntemidir. Yüksek üretim oranları sunar ancak ileri düzeyde planlama ve yönetim gerektirir. GroundHog tarafından yayımlanan bu eKitap, Short Interval Control (SIC) ve

Short-term Planning in Longhole Stoping Operations Turkish

Short-term Planning in Longhole Stoping Operations … Read More

GroundHog Cloud Maintenance Solution Turkish

Madencilik ekipmanlarının verimli şekilde çalışır durumda kalması, üretim hedeflerine ulaşmak için kritiktir. Bu eKitapta, GroundHog Bulut Bakım Çözümünün madenlerde duruş sürelerini nasıl azalttığını, ekipman ömrünü nasıl uzattığını ve bakım süreçlerini reaktiften proaktife nasıl dönüştürdüğünü anlatıyoruz. Yeraltı ve açık ocak madenleri