We’ll talk about how we can control ore dilution using High-Precision GPS and Geology & Ore Solutions to make mining more efficient, safer, and more sustainable. In this first part, we’ll give a general overview of the types of dilutions in open-pit mines and how dilution can reduce the value of the mine. … Read More

Blog

Risk Assessment in Mining: Staying Vigilant to Minimize Hazards and Accidents

A Risk Assessment is vital in mining to identify and control hazards before starting a task. It involves evaluating the likelihood and severity of potential risks from equipment, environmental conditions, and operator competency. By conducting assessments in the field, miners can implement the right safety measures to reduce accidents and ensure safe operations. … Read More

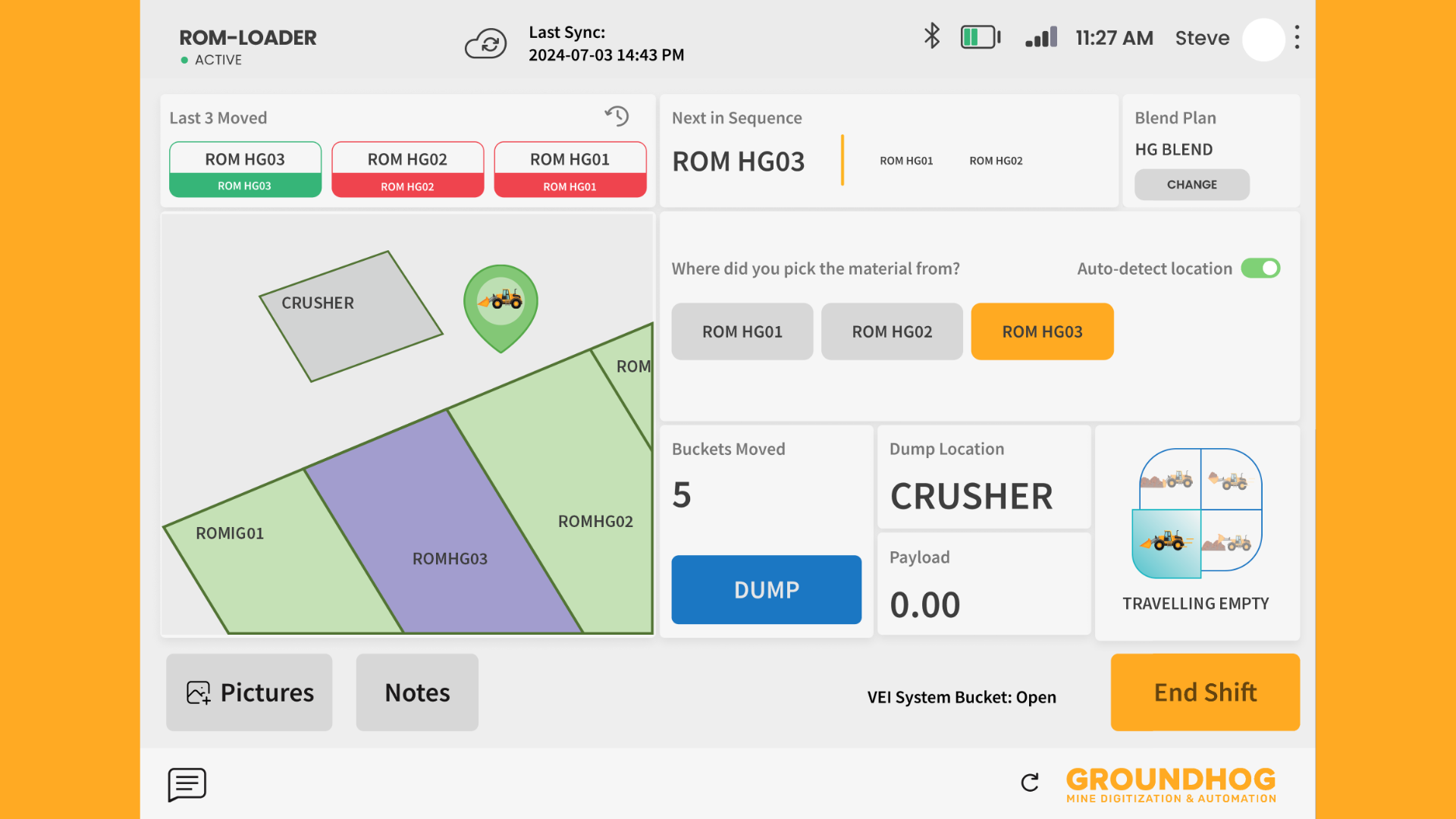

ROM Loader: 5 Powerful Reasons Mills Experience Lower Yield and How to Skyrocket Yield and Throughput

5 Reasons Mills Have Lower Yield and How to Improve Yield and Throughput via ROM Loader … Read More

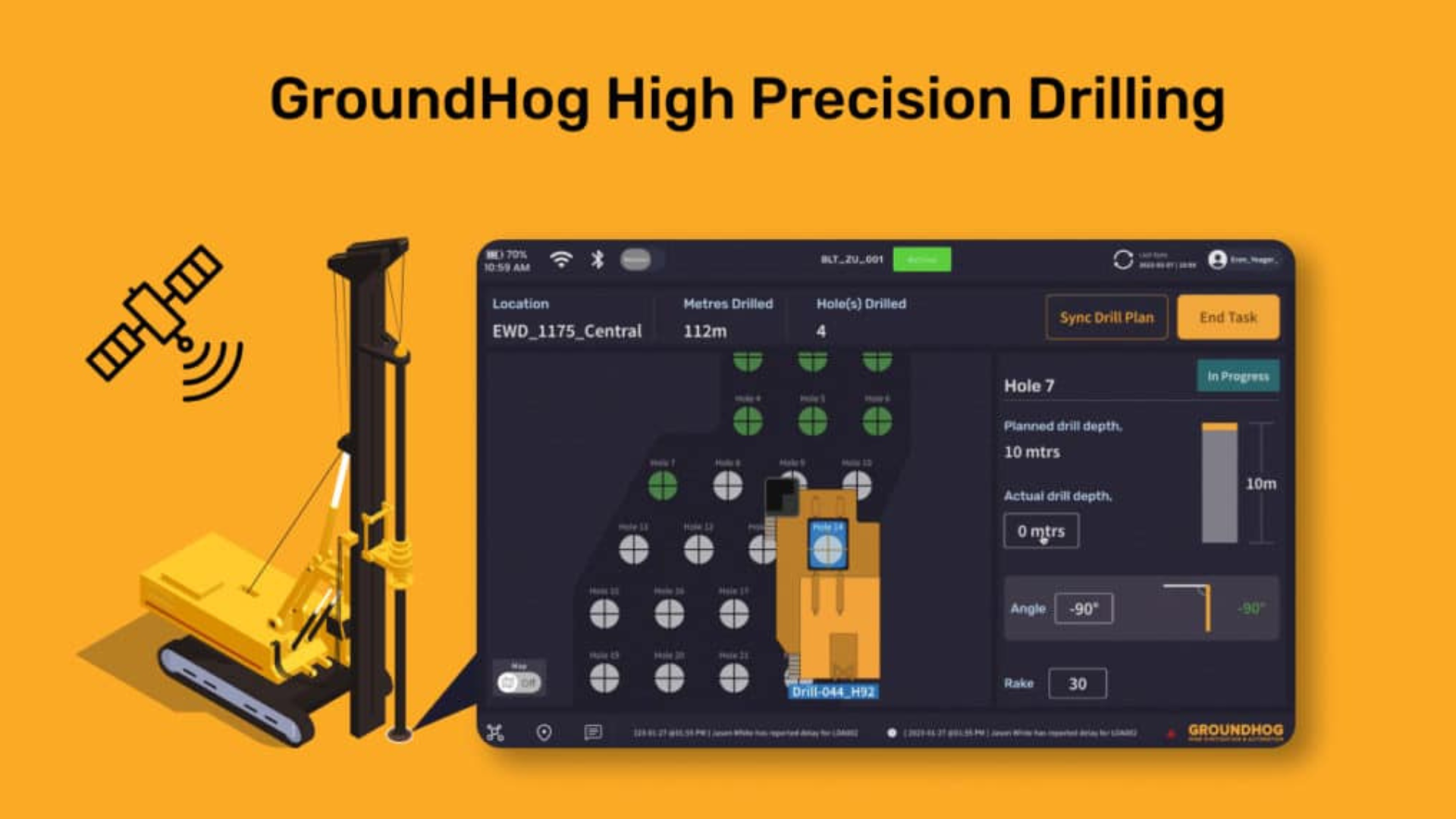

Drilling Revolutionized: 4 Powerful Ways GroundHog is Leading the Charge with High-Precision Solutions

GroundHog is revolutionizing the mining industry with its high-precision solution that sets a new standard for precise drilling operations. With strategically positioned base stations, RTK receivers, and dual antennas, the solution ensures optimal signal coverage and highly accurate position information, even in complex ore bodies. The GroundHog Operator app offers a cohesive approach for mining operators, combining advanced visualization and tracking features with precise data collection for improved efficiency. GroundHog’s innovative technology addresses common drilling challenges, such as deviations in drill holes, safety issues, and poor data quality in QA/QC. With its commitment to innovation, efficiency, and safety, GroundHog is leading the charge in advancing mining practices. … Read More

Caterpillar Telemetry Data Extraction: A Powerful Technical Guide – Part 1

Mastering Caterpillar Telemetry: A Step-by-Step Guide to Efficient Data Extraction and Analysis Our Journey into Caterpillar Telemetry When we started at GroundHog, our expertise was firmly rooted in software development for mining companies. Our flagship product was (and remains) our

How Mines Use GPS for Unstoppable Efficiency: 5 Powerful Benefits

Starting in the early 90’s, Mines use GPS in a wide variety of ways. While technological advancements have played a crucial role in enhancing operational efficiency, safety, and productivity, GPS is one innovation that has revolutionized the way mines use

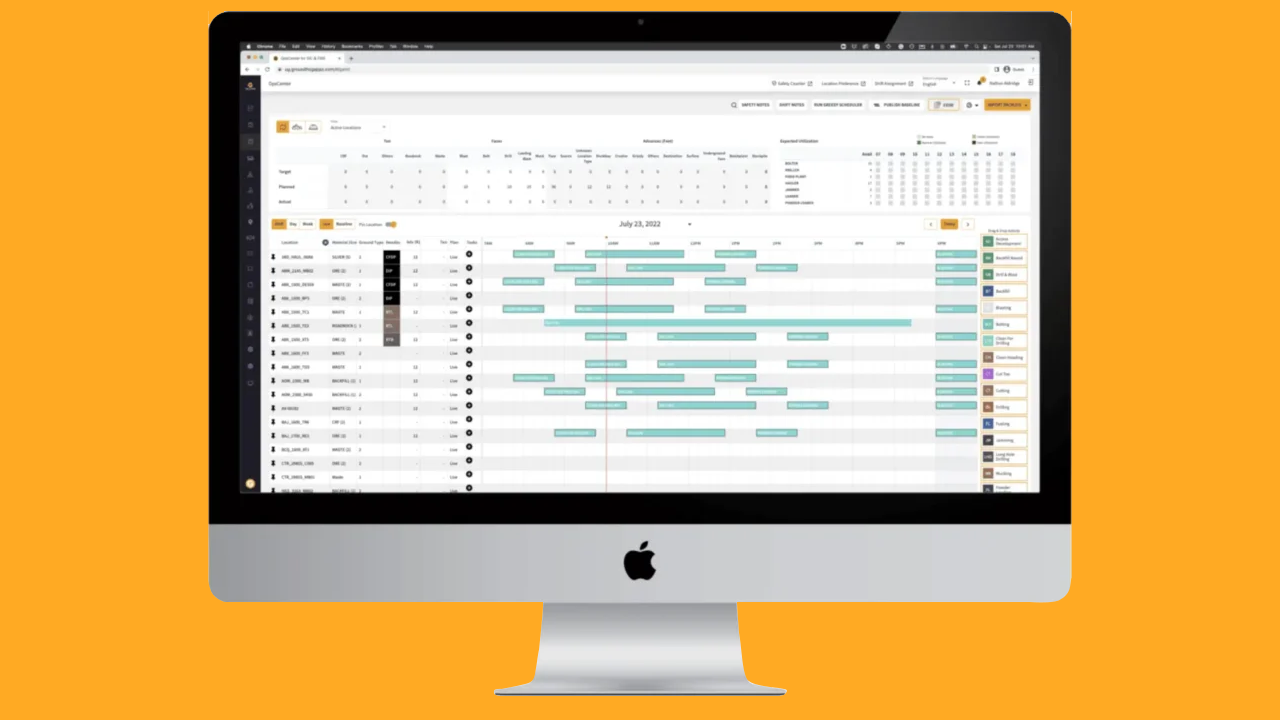

Empowering Mining Operations with Short Interval Control: 5 Strategies for Greater Success

Short Interval Control (or SIC) is a framework of structured processes that help you identify and act on opportunities to improve the effectiveness and efficiency of production. SIC has always been in use at conventional and traditional types of businesses such

Short Interval Control: A Powerful Process for Boosting Mining Efficiency

Short Interval Control has become the standard process to improve overall mining efficiency in the mining industry. The Global Mining Guidelines Group, an industry standards organization, has also come out with an actionable roadmap any mine can use to deploy

Discover the Best Choice: RTK or GNSS for Optimal Mine Performance

RTK (Real-Time Kinematic) and GNSS (Global Navigation Satellite System) are both widely used technologies for utilizing GPS in mining operations. While they share the common goal of providing accurate positioning information, there are important differences between the two approaches. RTK:

Hazard Training That Empowers Your Team with Jobsite-Specific Safety

Is your company taking the necessary steps to ensure the safety and productivity of its employees? While many companies focus on general training for new hires, they often overlook the importance of jobsite-specific hazard training. In order to truly empower your team, it’s crucial to provide comprehensive training that addresses the unique hazards of each jobsite. Certified Safety Professional John Fowler emphasizes the importance of this final piece of the training puzzle, and shares his insights on how best to implement this essential training. Discover how you can ensure the safety and success of your team with jobsite-specific hazard training. … Read More