How Mines Use GPS for Unstoppable Efficiency: 5 Powerful Benefits

Starting in the early 90’s, Mines use GPS in a

Transform mining operations with GroundHog FMS for High Precision Digging

Improve ore quality. Reduce downtime. Minimize losses.

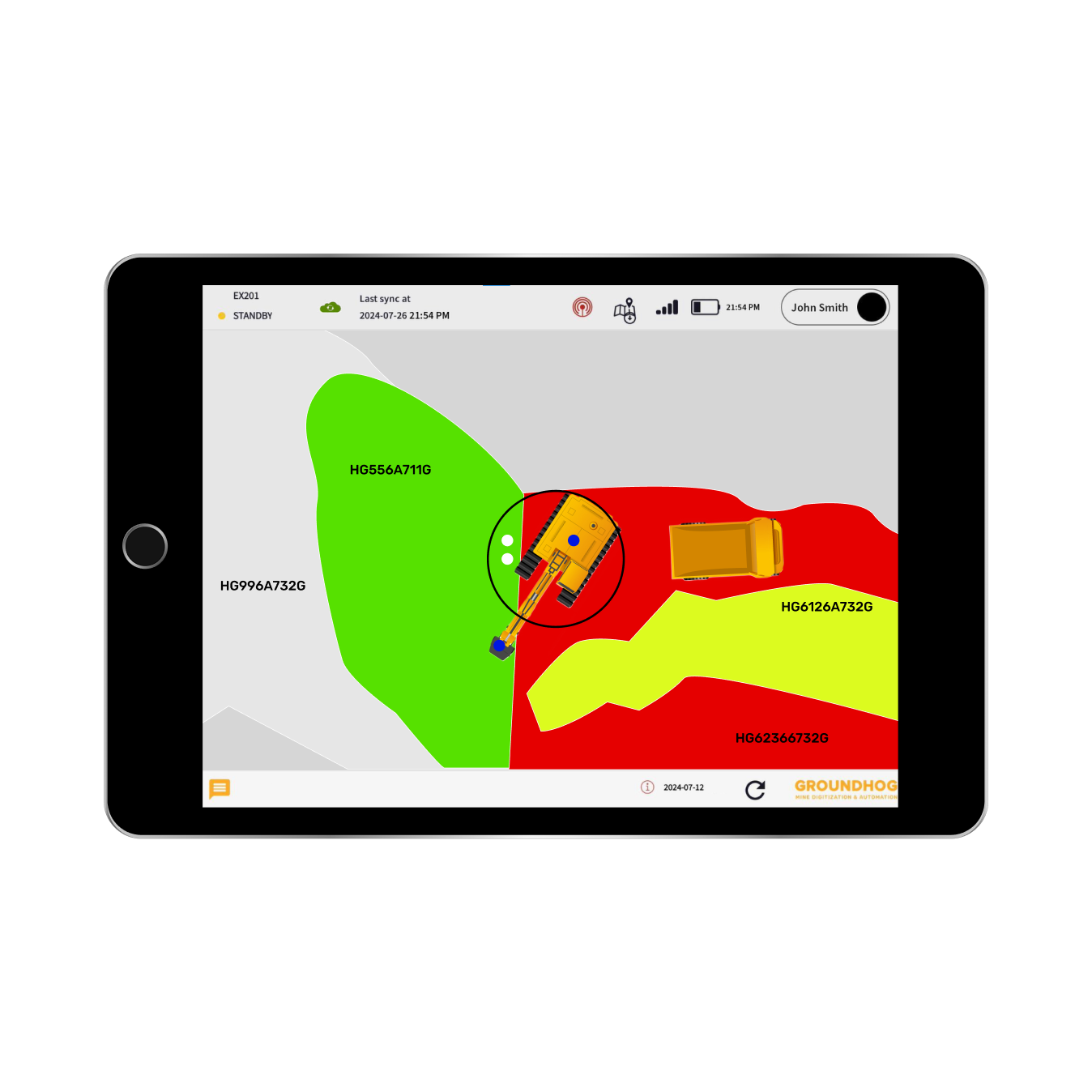

Reduce Ore Dilution Through Precise Positioning and Real-Time Data

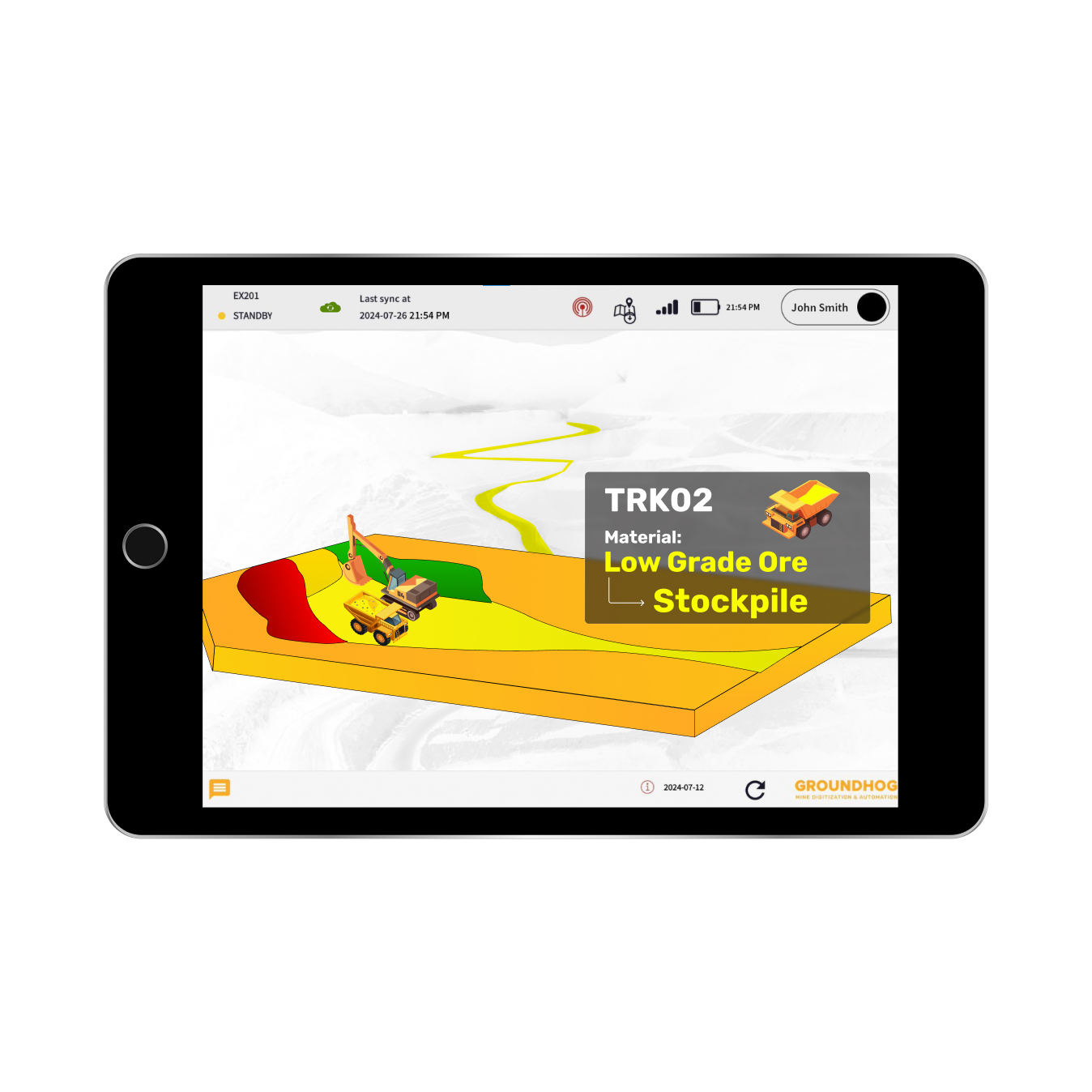

GroundHog’s advanced FMS for High Precision Digging technology offers operators real-time visibility and precise positioning data, allowing them to navigate equipment along designated points with centimeter-level accuracy.

Comprehensive Data Tracking from Source to Stockpile

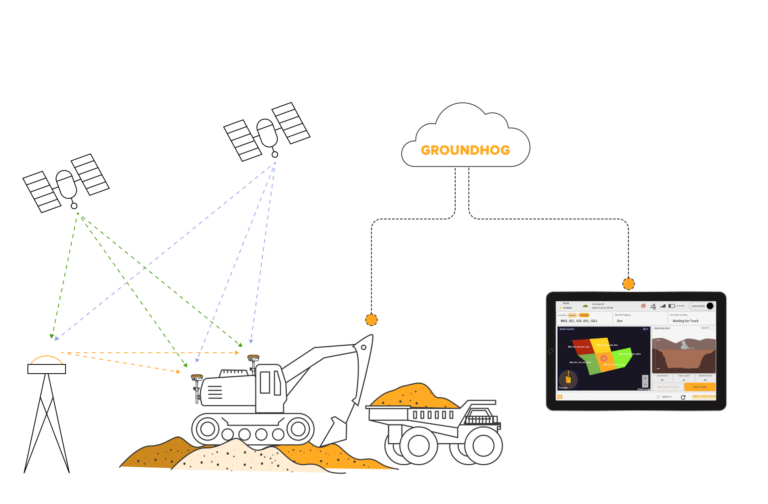

The FMS for High Precision Digging process involves several key components: Two GPS RTK receivers are installed atop the cab, while three third-party IMU sensors are positioned along the boom. GroundHog’s FMS software processes data from these GPS receivers and IMU sensors to calculate the shovel tip’s position.

Real-Time Monitoring and Accurate Tracking

Operators and dispatchers can view dig blocks, ore quality, and location on their screens in real-time. GroundHog OpsCenter tracks material movement from source to destination, facilitating accurate reconciliation between plan and actual performance at shorter intervals and effectively managing deviations.

Precision Positioning and Comprehensive Integration

The system provides high-precision bucket positioning within centimeters. GroundHog’s technology integrates with mining operations planning and management systems, offering a holistic solution.

Improve Digging Accuracy with Advanced Tracking System

Starting in the early 90’s, Mines use GPS in a

RTK (Real-Time Kinematic) and GNSS (Global Navigation Satellite System) are

RTK (Real-Time Kinematic) High Precision GPS technology comes is primarily

High precision digging involves using advanced technology and techniques to achieve accurate and controlled excavation, ensuring precise depth, alignment, and positioning.

It ensures accuracy in excavation projects, minimizes the risk of damage to surrounding infrastructure, reduces excavation errors, and improves overall project efficiency and safety.

Technologies include GPS systems, laser-guided excavation equipment, real-time data monitoring, automated digging systems, and advanced digger controls.

It enhances accuracy in digging, reduces rework and material wastage, improves safety by avoiding accidental damage to utilities or structures, and ensures better project outcomes.

Challenges include the high cost of advanced equipment, the need for skilled operators, and maintaining accuracy in varying soil and geological conditions.

By providing accurate depth and positioning, it helps avoid accidental damage to existing utilities, minimizes risks associated with excavation, and improves overall site management.

Data is collected through sensors, GPS, and monitoring systems integrated into excavation equipment, and is used to adjust digging parameters and ensure adherence to project specifications.

Yes, it can be integrated with technologies such as real-time mapping, automated construction management systems, and geological modeling for enhanced project coordination and efficiency.