Drilling Revolutionized: 4 Powerful Ways GroundHog is Leading the Charge with High-Precision Solutions

GroundHog is revolutionizing the mining industry with its high-precision solution

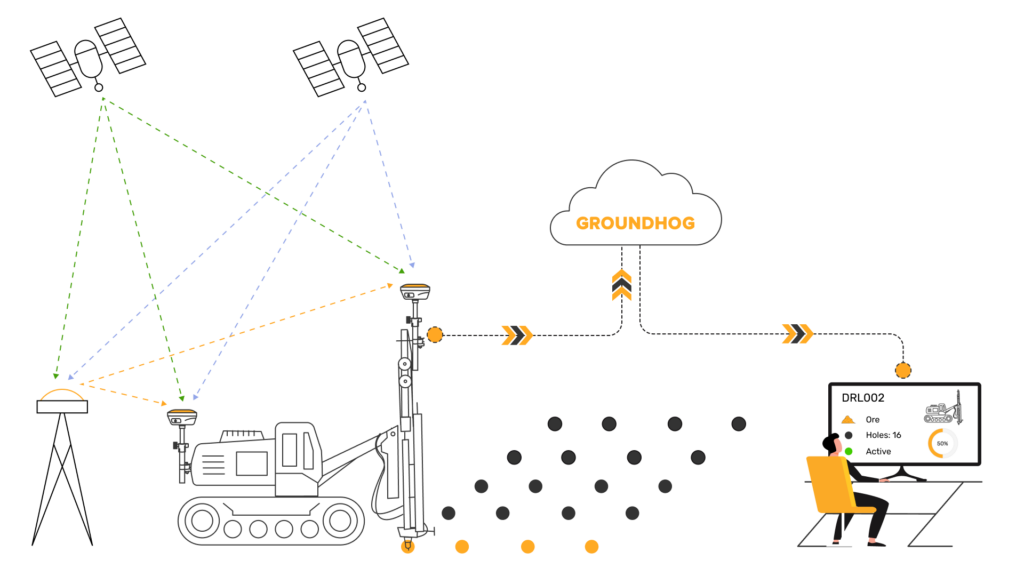

GroundHog High Precision Drilling utilizes advanced technology to deliver real-time centimetre-level positioning accuracy in drilling operations for open-pit mines.

Centimetre-level High Precision GPS Ensures Exact Drill Placement.

GroundHog utilizes off-the-shelf High Precision GPS hardware with centimeter-level accuracy. Compatible with RTK GNSS services, it ensures 2cm precision, providing accurate drill locations every time.

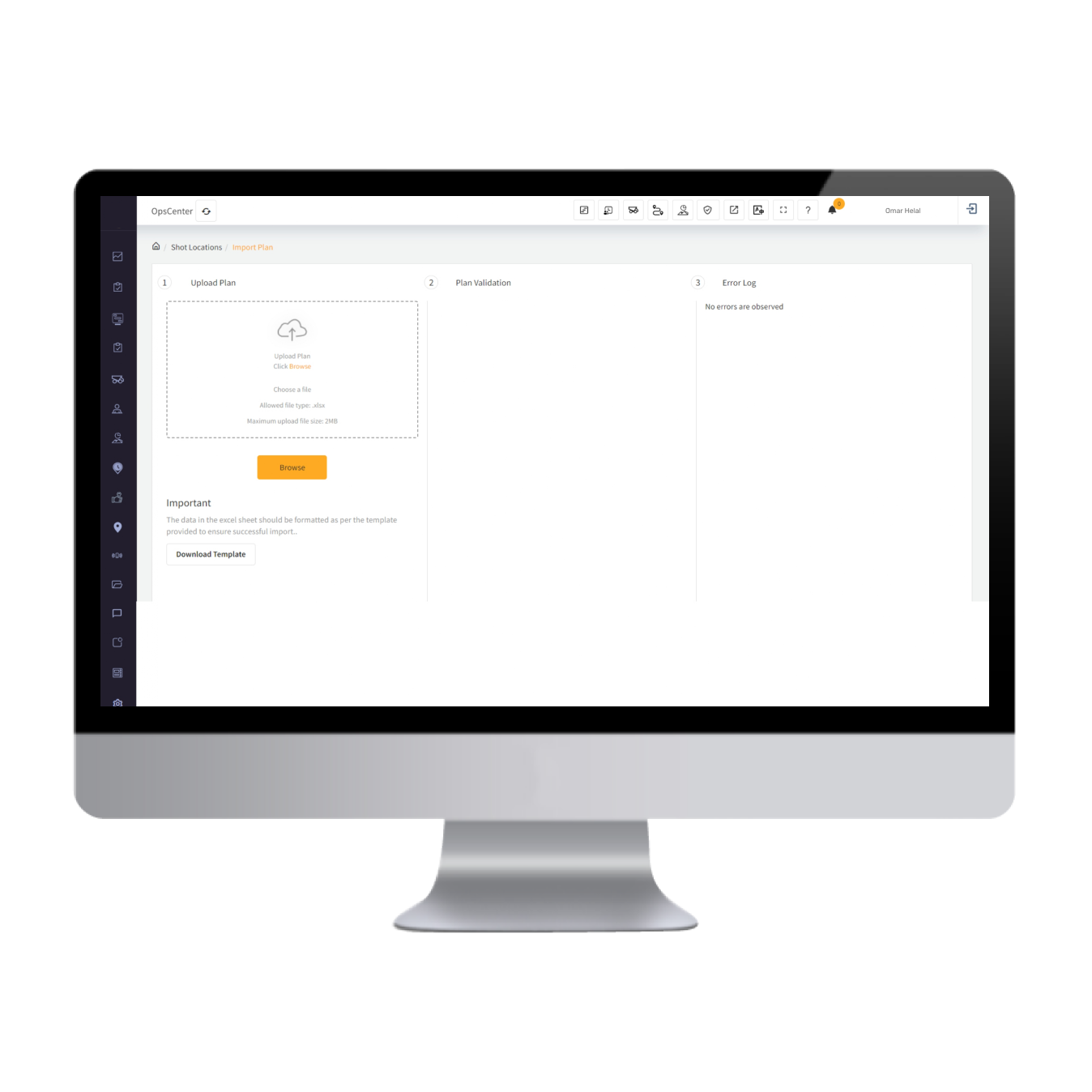

Optimize Drilling Operations with Instant Drill Plan Access.

Mine engineers or dispatchers upload the drill plan to the GroundHog OpsCenter, where it is securely stored in the cloud. This plan is then instantly available in real-time on the drill operator’s application, ensuring efficient communication and smooth execution of the drilling plan.

Track and Comply with Drill Plans Effortlessly

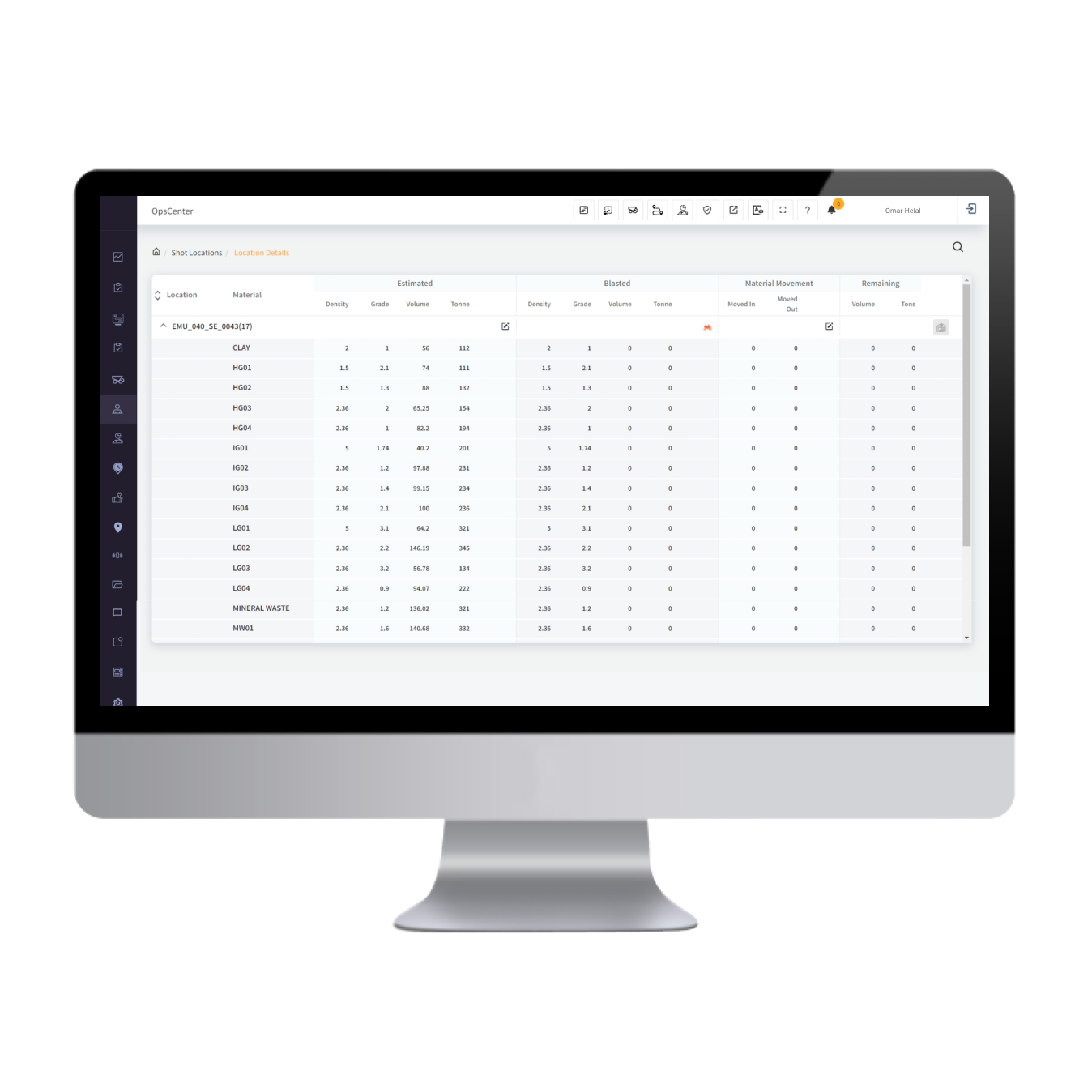

Our Easy-to-use Fleet Management app acts as a guiding tool, enabling operators to execute drilling plans with accuracy. It continuously monitors any deviations from the plan, offering real-time feedback to enhance operational precision.

Enhancing Collaboration and Coordination in Drilling Operations

The data generated by the FMS operator app is seamlessly transmitted to the GroundHog OpsCenter via the cloud. This allows dispatchers and mine engineers to receive real-time updates on performance against the plan.

GroundHog High Precision Drilling offers real-time centimetre-level positioning accuracy for open-pit mining operations.

GroundHog is revolutionizing the mining industry with its high-precision solution

Starting in the early 90’s, Mines use GPS in a

RTK (Real-Time Kinematic) and GNSS (Global Navigation Satellite System) are

High precision drilling refers to the use of advanced technology and techniques to perform drilling with accurate depth, alignment, and positioning, enhancing the quality and efficiency of drilling operations.

It improves resource extraction accuracy, minimizes drilling errors, reduces waste, and enhances overall operational efficiency by ensuring drills are accurately targeted and aligned.

Technologies include GPS systems, advanced drill rigs, real-time data monitoring, downhole sensors, and automated drilling systems.

It provides more accurate data on ore body locations and quality, leading to more reliable resource estimates and better mine planning.

Challenges include the high cost of technology, the need for skilled operators, and maintaining accuracy in varying geological conditions.

By ensuring accurate drilling, it reduces the risk of unintended collisions, improves the stability of drilled areas, and helps avoid hazardous conditions.

Data is collected through sensors and monitoring systems integrated into the drill rig and analyzed using specialized software to assess drill performance and ore body characteristics.

Yes, it can be integrated with technologies such as real-time mapping, automated ore sorting, and advanced geological modeling for enhanced mining operations.

While initial costs may be higher due to advanced technology and equipment, the benefits of increased accuracy and efficiency can lead to long-term cost savings and improved profitability.