Deployment Model for Site: Underground FMS

Site Information

GroundHog Deployed the OpsCenter, FMS Operator app, Supervisor app, and Power-BI reporting at a Copper Mine in Nevada, USA.

Pre-GroundHog Set-Up & Goals with GroundHog

The site used paper to create shift plans and shift reporting before GroundHog. With GroundHog, the goal was to develop shift plans in OpsCenter, have operators enter data directly via tablets, and generate daily reports from OpsCenter.

Operators tracked the information below:

- Trip Counts (source –> destination)

- Trip start time, Trip end time

- Pre and Post – Engine Hours (SMU Hours)

- Mucker logs

- Rockbreaker logs

- Simba and Jumbo drill logs

Implementation

GroundHog worked with the site team to import initial data such as:

- Names of all locations, (faces, grizzly, stockpiles, crushers)

- Names, Makes, Models, Capacities of all primary and auxillary equipment

- Names, roles, skillsets, and safety training documents of all miners

- Material types and grades

- Consumable types and quantities

First, the data was set up in the test server and then moved to the Production server.

Subsequent enhancements:

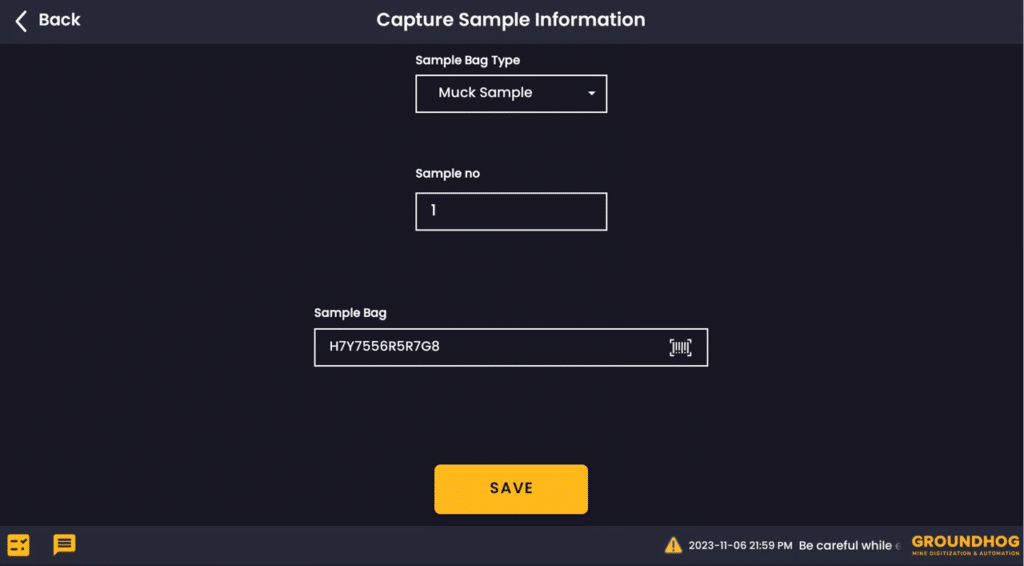

- Capturing data for sample bags – details such as hole name, # muck samples, etc. are captured.

- Ability to do monthly and weekly budget plans for footage and tonnage

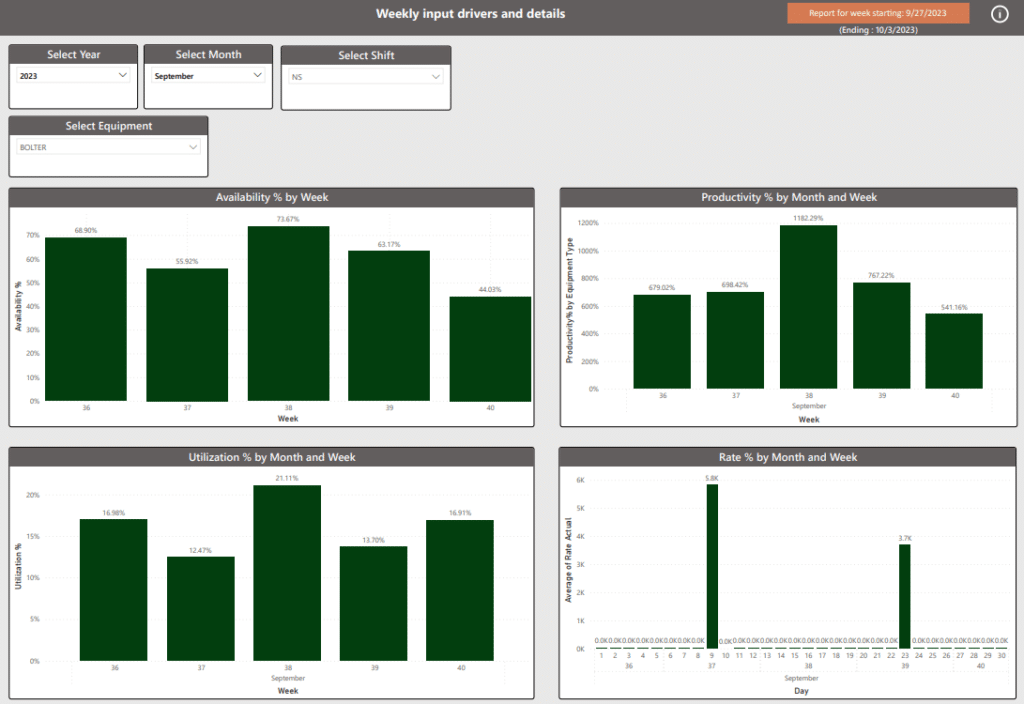

- Customized Power BI reports. Some of the reports created are as below:

- Finance & Operations : Cost Variance Report

- Daily Variance Report

- Weekly Variance Report

- Monthly Variance Report

Support

The GroundHog team started with weekly calls with sales and support teams during initial production rollouts and ultimately transitioned to a bi-weekly customer success call.