AI Based Fuel

Monitoring System

Fuel is the 2nd highest OpEx at a mine site

Mines use GroundHog to reduce fuel costs

by 20% or more

fuel thefts

Idling Fuel Use

Fleet Efficiency

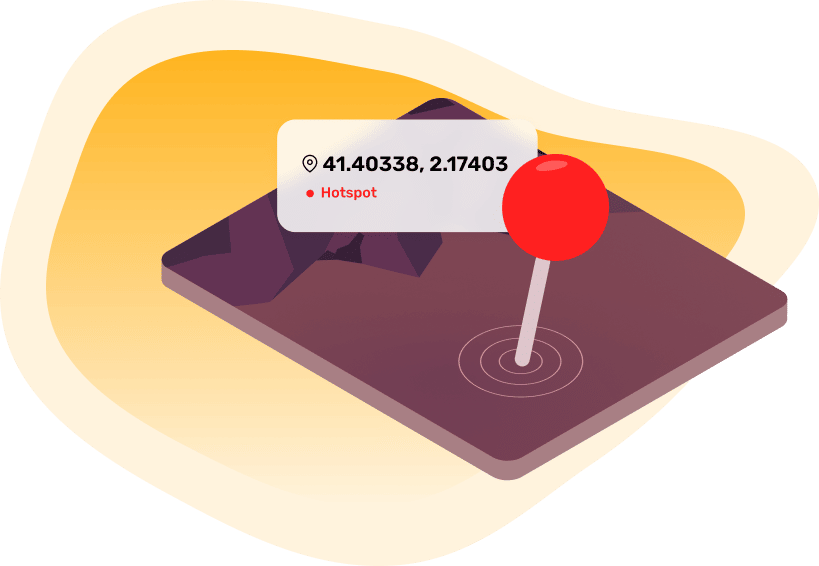

Live GPS

Tracking

Track all machines, in real time to analyze fuel consumption rates, idling rates, and no-go-zones to prevent theft

Simple, Retrofit

install

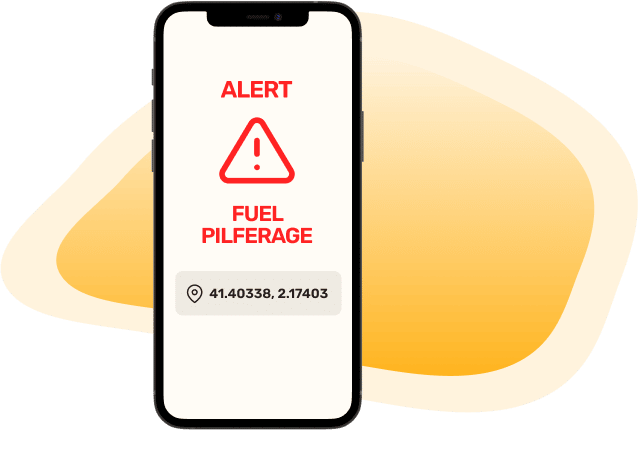

Diesel Theft

Alerts

Get real-time alerts when the system detects unusual drops in fuel levels, especially when equipment is outside the mine site

Operator Behaviour

Monitoring

Monitor driver performance KPIs such as harsh acceleration, high RPM, and harsh braking, and provide corrective training to save on fuel costs

As per 2017 statistics, about 8% of

diesel filled in trucks was stolen during transit

GroundHog’s Fuel management system uses data from on-board fuel sensors or from retrofit fuel level sensors inside or outside the fuel tanks of Heavy Equipment and Light Vehicles used on mine sites. Real-time analytics on data transferred to the GroundHog Fuel Monitoring System allows supervisors and management to detect fuel theft or unreasonable large fuel burn at various segments of the hauling and tramming zones, thus helping to find ways to save 30% or more on fuel costs. Analysis done at our customer sites suggest that the system pays for itself in 3-4 months.

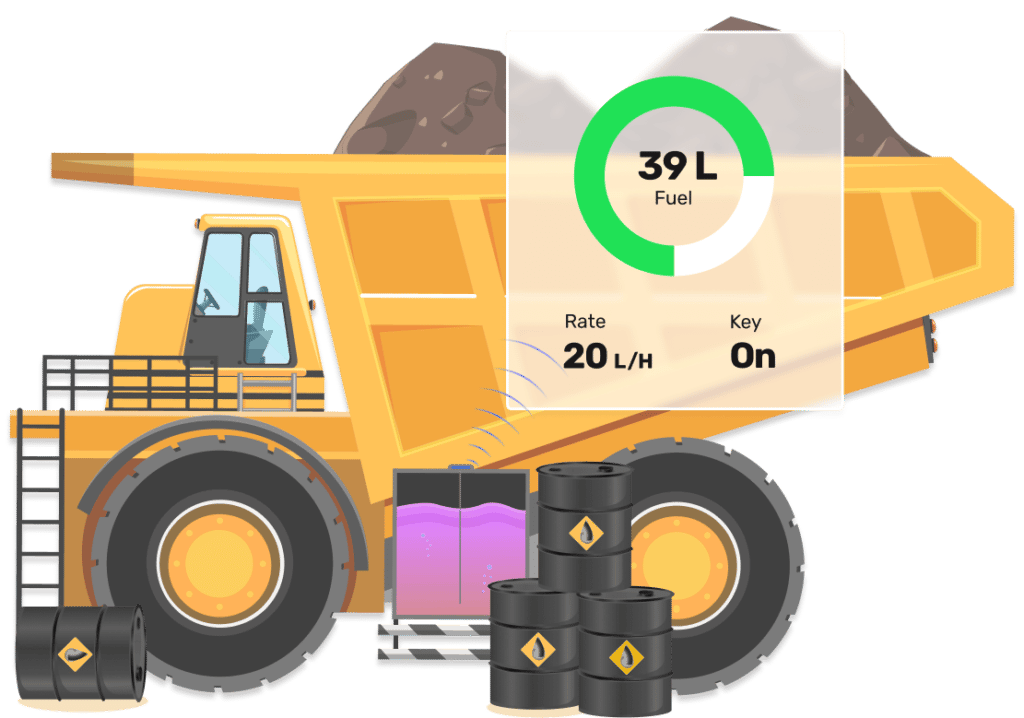

Live Fuel Consumption

with GPS Tracking

Fuel sensors continuously feed information to an on-board dual-function tablet with an inbuilt GPS chip to log fuel levels, key on/off status, idling status, fuel consumption rates, and operator ID. All data is logged in an online/offline mode and is sent to the GroundHog cloud to real-time visualization of fuel levels and consumption patterns across the entire fleet of Heavy Equipment and Light Vehicles

Fuel analytics with

consumption hotspot

detection

GroundHog’s AI driven Fuel Analytics helps you determine fuel consumption hotspots in your mine — especially for loaded haulage. Fuel Analytics combined with GroundHog’s Fleet Management System and GroundHog’s Load-cell Tonnage sensors help mine planners identify data driven ramp design improvements for more fuel efficiency and better transmission subsystem health.

Fuel theft alerts with Driver

and Location information

GroundHog’s AI based integrated Fuel Management and Fleet Management System gives supervisors and mine managers alerts when the system recognizes drops in fuel levels correlated with ignition state and equipment speed.

Retrofit old equipment with

ruggedized Capacitive Sensors

or Ultrasonic Sensors

For Heavy Equipment that do not have built in Fuel Sensors that report fuel levels and consumption rates through the CANBUS or OBD II port, GroundHog installs sensors to get fuel level readings directly from the fuel tanks. Capacitive sensors require drilling in the Fuel Tank whereas Ultrasonic sensors DO NOT require drilling the Fuel Tank. Retrofit sensors have IP68 dust proof and water proof, IP69k ingress protection, and Exd II CT5 explosion proof ratings.

Automated consumption rates

calculation for loaded haul trucks

and empty haul trucks

For Heavy Equipment that do not have built in Fuel Sensors that report fuel levels and consumption rates through the CANBUS or OBD II port, GroundHog installs sensors to get fuel level readings directly from the fuel tanks. Capacitive sensors require drilling in the Fuel Tank whereas Ultrasonic sensors DO NOT require drilling the Fuel Tank. Retrofit sensors have IP68 dust proof and water proof, IP69k ingress protection, and Exd II CT5 explosion proof ratings.