Wisdom from the Trenches

Perspectives, Insights, Learnings from Digitizing some of largest mines in the world

Technical Guide: Extracting Telemetry Data from Caterpillar Equipment – Part 2

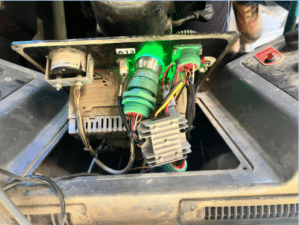

Technical Guide: Extracting Telemetry Data from Caterpillar Equipment Welcome back to our journey into

Technical Guide: Extracting Telemetry Data from Caterpillar Equipment – Part 1

Technical Guide: Extracting Telemetry Data from Caterpillar Equipment Our Journey into Telemetry When we

Optimizing Maintenance: Key Metrics to Maximize Equipment Performance

With the rapid expansion of the mining industry and rising competition, companies are continually

Mobile Equipment Safety Program

Over the years, in the mining industry, there have been dozens of fatalities and

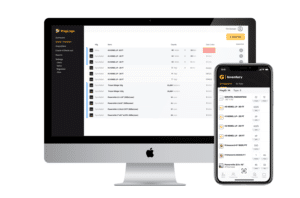

Launching GroundHog Maintenance Cloud: Revolutionizing Mining Maintenance for Planners and Reliability Engineers

California, USA — GroundHog, a leading provider of digital solutions for the mining industry,

Recognizing Hazards using Written Procedures

People often say that mining is a dangerous industry, but I think a better

Behind the Scenes: A Day in the Life of an Underground Miner

In this detailed exploration, we delve into the intricacies of an underground miner’s day,

OSHA’s Crane Operator Requirements

In 2018, the Occupational Safety & Health Administration (OSHA) began enforcing the requirement that

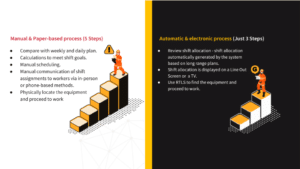

Short Interval Control Training: Best practices to transition from paper-based systems to Digital.

Short Interval Control Training is key to transition a mine from traditional paper-based Short

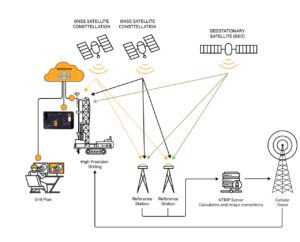

Technology Behind High Precision Drilling for Better 100% Drilling Accuracy First Time, and Every Time

In this article, we will go over the Technology used to achieve high precision

Navigating Challenges in Conventional Drilling: A Collective Exploration

At GroundHog, our commitment to continuous improvement and collaboration drives our pursuit of solutions

MSHA- 2023 LEARNINGS

On December 6th, the Mine Safety and Health Administration held the final quarterly stakeholder’s

GroundHog’s Ore Spotter App: Your Ore Routing Maestro Unleashed!

California, USA — GroundHog, a leader in innovative mining solutions, is proud to unveil

Digging Deeper: Revolutionizing Mining with High-Precision GPS & Telemetry

Diggers are the most essential equipment in an open pit mine. These giants in

GroundHog Install at Underground Copper Mine in Zambia

Deployment Model for Site: Underground SIC Site Information GroundHog Deployed the OpsCenter, Mine Manager

Safeguarding Against Silica: A Call to Action for Enhanced Safety Measures in Mining

In March of 1930, a massive construction project began near Gauley Bridge, WV, to

GroundHog Install at Underground Copper Mine in Nevada, USA

Deployment Model for Site: Underground FMS Site Information GroundHog Deployed the OpsCenter, FMS Operator

GroundHog Install at Underground Gold Mine in Ontario, Canada

Deployment Model for Site: Underground FMS Site Information GroundHog Deployed the OpsCenter for Shift

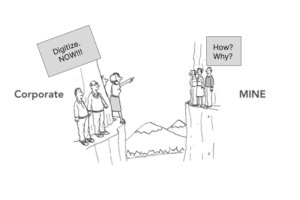

Why Mine Digitization Fails (at Some Sites)

Over the past 11 years, we’ve been involved in digitization initiatives for many large

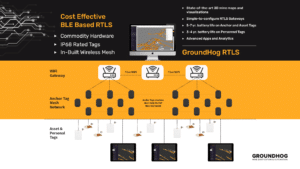

How stuff works: RTLS – Underground GPS to track Personnel and Assets in Mines and Tunneling projects for Safety and Efficiency.

Underground mines are like black boxes. Unlike surface mines, where you can have a

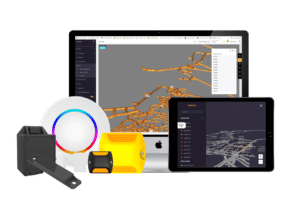

#getStuffDone – Our latest Launches!

We at GroundHog believe in simplifying mine operations and are always looking for ways

5 benefits of Real-Time Location Systems (RTLS) for meeting compliance requirements

Mining companies operate in a highly regulated environment, facing overwhelming compliance requirements to ensure

Jobsite Specific Hazard Training

Training is one of the most important things that a company can do to

Enhancing Efficiency and Safety: Automatic Trip Counting in Open Pit Hauler-Loader Operations

Introduction In the mining industry, the efficient movement of materials is crucial for productivity

GroundHog Install at SMS in India

Deployment Model for Site: Underground SIC & Weighbridge Integration Site Information GroundHog Deployed the

GroundHog Install at Gold mine in Africa

Deployment Model for Site: Open Pit FMS Site Information GroundHog Deployed the OpsCenter for

GroundHog at Underground Zinc Mine

Deployment Model for Site: Short Interval Control & Fleet Management System with Supervisor App

GroundHog at Underground Copper Mine in USA

Deployment Model for Site: Mine Control (Dispatch) Mode Site Information Cementation USA deployed GroundHog’s

Automating Trip Counting in Mines Using Tilt Sensors

The Role of Trip Counting in Mining Mining operations involve transporting materials from excavation

6 Benefits of Purpose-Built Remote Monitoring Technologies

Benefits of Purpose-Built Remote Monitoring Technologies As technology continues to advance the way mines

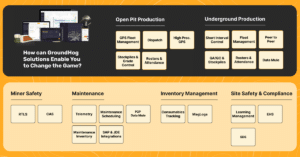

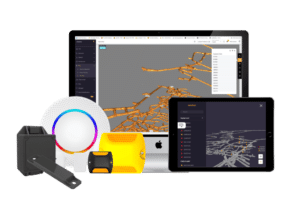

GroundHog Platform Overview

GroundHog provides a comprehensive platform for operations, maintenance, quality, and safety. Here is an

Building a Safer and More Productive Mining Workforce: The Power of Quality Safety Training Systems for Mines and Mining Contractors

Safety Training for a miner on how to operate a piece of equipment, or

Preventing accidents with key operational technologies

Mining is demanding by nature, and the industry carries high stakes around the clock.

A Step-by-Step Guide to BLE Beacon-Based RTLS System Hardware Installation in Underground Mines

We have been focusing on Real Time Location Systems (RTLS) in our Mine Digitization

Revolutionizing Mining Efficiency: Tilt Sensors for Dump Cycle Count Automation with Unparalleled Precision

#mining #innovation In a bold stride towards cutting-edge innovation in the mining industry, our

Why GroundHog is the Superior Choice over Newtrax and MST for Your Mine

Last week in Part I of our series on Real Time Locating Systems, we

Leverage Telemetry to Cut Heavy Equipment Maintenance Costs

Every mine manager worth his salt uses Heavy Equipment Availability and Utilization as one

RTK or GNSS? What should a mine use?

RTK (Real-Time Kinematic) and GNSS (Global Navigation Satellite System) are both widely used technologies

RTK High Precision GPS: Because Mines need Grade Control and Compliance to Mine Design

RTK (Real-Time Kinematic) High Precision GPS technology comes is primarily used to achieve centimeter

How Mines use GPS

Starting in the early 90’s, Mines use GPS in a wide variety of ways.

Can FMS and Telemetry data maximize Operator Performance? Tips to broaden the usage of FMS and Telemetry data.

Mines have been leveraging fleet management systems (FMS) and telemetry data for decades. They

5 ways to improve Asset Tracking in Underground Mines using RTLS

Asset tracking in underground mines is a critical part of your daily operations –

RTLS in Underground Mines: 12 ways RTLS is Revolutionizing Safety and Efficiency

Introduction Welcome to our comprehensive guide on RTLS in underground mines. In this article,

GroundHog: Leading the Charge in the Future of Underground Mining Software

There is a revolution happening in the mining industry, and at the forefront of

Optimizing Digital Explosives Inventory Management for Improved Efficiency and Safety

At GroundHog, we are committed to revolutionizing the way mines do their digital explosives

Unearthing the Future: Predictions on Underground Mining Fleet Management Systems.

Change is the only constant. Nowhere is this axiom more fitting than in the

Unlocking the Power of Underground Mining Fleet Management Systems: The Key to Greater Output

The world of mining presents a complex array of challenges, particularly when it comes

The Reality of Real Time Locating Systems (RTLS) – They’re Not All Created Equal

For the next few issues of our Mine Digitization and Automation series, we going

Don’t let the mining labor shortage hold you back; embrace the transformative power of Short Interval Control to get 37% more tonnes in 9 months

In the rapidly changing world of mining, where precision, efficiency, and safety are paramount,

How Mine Digitization and Automation is Increasing Productivity and Safety in Mining

In today’s rapidly evolving technological landscape, including Autonomous vehicles and ChatGPT types of Generative

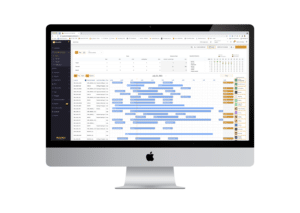

Manual v Digital series: Shift Allocation

This week we’re discussing the benefits to Shift Allocation as we continue to contrast

Introduction to Manual vs Digital Series

We’re back with the Mine Digitization and Automation series. For the past several installments,

How Safety Managers save at least one month per year with LMS

Safety Managers who rely on Groundhog LMS know first-hand how much time they can

The advantages of having Wi-Fi in an underground mine

Wireless internet connectivity, or Wi-Fi, has become ubiquitous in many industries and environments. Still,

Leveraging Technology to meet your Operational KPIs

It’s been said that you can’t master what you don’t measure, and this couldn’t

How a Mining Foreman Saves Time Each Day

When you’re a foreman at a mine, you’re responsible for almost everything that happens

Roadmap for Digitization & Automation Part II

Last time in our Mine Digitization and Automation series, we discussed developing a five-level

Roadmap for Digitization & Automation – Part 1

We’ve introduced Change Management into our Mine Digitization and Automation series, talked about the

Why Fleet Managers Should Care About Fuel Tracking

Welcome back to our Mine Digitization and Automation series, where we share proven strategies

Powerful Minestar Reporting using Power BI in 30 minutes

First off, what is Minestar Minestar Reporting is part of is Caterpillar’s Minestar Fleet

Introduction to Change Readiness Part II

Last time in our Mine Digitization and Automation series, we started to delve into

Introduction to Change Readiness

In the last installments of the Mine Digitization and Automation series, we looked at

Short Interval Control: An Essential Process for increasing mining efficiency.

Short Interval Control has become the standard process to improve overall mining efficiency in

7 Metrics that every fleet manager should track – Part 1

We sincerely hope you’ve been enjoying our Mine Digitization and Automation series, where we’ve

The Mine Digitization Blueprint – Practical Considerations

In this post, we are going to look at is more practical aspects of

Why does Digital Transformation in Mining Matter

Last time in our Mine Digitization and Automation series, we loosely defined what we

Road to Digital Transformation

Welcome to Groundhog’s new Mine Digitization and Automation series. We’ll be presenting articles that

Drilling Deeper: The Advantages of Long Hole Open Stoping in Underground Mining

Over the past few years, Long hole open stoping is being increasingly used in

5 advantages of using BEVs in Mining

Battery electric vehicles (BEVs) have the potential to transform the mining industry by reducing reliance on fossil fuels and lowering operating costs.

Six Reasons Underground Mine Managers need to use Face Utilization as an Operational KPI

The key objective of every mine manager is to get maximum tonnage from mines

New Mine Digitization Trends 2022

Mining sector is rising rapidly with the current digital expansion of the industry. Around

Short Interval Control (SIC) for Productive Mining

SIC in Mine Operation Planning is the backbone of efficient Mining. Maintaining the mine

9 New Technologies for Mine Digitization and Automation

INTRODUCTION In recent times, there has been increased emphasis on Mine Digitization and Automation

7 Steps to Prevent Fuel Theft in Mining Equipment (HEMMs) using Fuel Monitoring System

Fuel accounts for about 31% of OpEx at mine sites in developed mining markets

How CMMS can help mines increase Overall Equipment Effectiveness

Overall Equipment Effectiveness (OEE) is a well-known measurement method, used in the manufacturing industry,

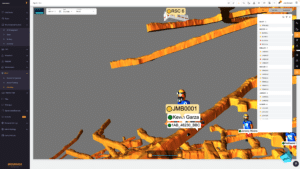

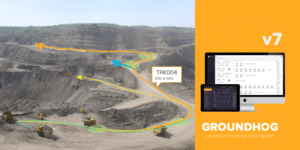

GroundHog v7 updates on Intelligent Dispatch and Grade Control

About Version 7.0 : GroundHog Apps, the leading global provider of connected mine software,

How Machine Learning transforming the mining industry

Over the past few years, Machine Learning in Mining was billed as a magic

Setting Expectations for Digital Transformation ROI

Everyone knows you need to set clear goals. You must have realistic expectations for

The Single Biggest Hurdle to Increasing Production Through Digitization

“We’ve always done things this way.” Anyone that’s ever tried to introduce digitization in

How the Pandemic is Pushing Mines to Digitize

All around the world, the pace of daily activities has taken on an entirely

The Power of IoT in Mining

Internet of things technology and connected workforces are hardly a new concept, unfortunately the

Three Ways to See Your Mine Come Back Stronger Than Ever after COVID-19

It’s easy to be negative in times like these. The world is going through

The Importance Of Heavy Equipment Maintenance

Optimizing machine output is a constant challenge in heavy machinery. In this article, we

How Mine Automation is increasing productivity and safety in the Industry

Mine Automation streamlines the process of capturing and analyzing data using IoT sensors. This helps shorten mine planning time and provides process consistency which yield in significant cost savings.

5 Strategies To Minimize Mining Operating Costs

Mining company strategies depend heavily on the current state of the market. When the

5 Strategies To Improve Mine Safety & Productivity

Mining has always been a very risky and dangerous business. Over the years, science

Here’s How GroundHog FMS Works With Your Mine

GroundHog FMS is a cutting-edge, yet very affordable fleet management system for mining companies. We’ve

Top 5 Benefits of Digitization in Mining

Digitization in mining is focused at making mining better than before. And “better” really

Using Short Interval Control To Enhance Mining Operations

Short Interval Control (or SIC) is a framework of structured processes that help you identify

4 Factors That Are Driving Digital Transformation In The Mining Industry

The mining industry is going through a bleak phase. According to a World Economic

4 Reasons To Adopt A Fleet Management System For Underground Mining

Mining is a complex business that involves management of a large fleet of vehicles

Infographic – Digital Transformation in The Mining Industry

With profits down the global mining community is looking towards digital innovation to provide

Top 5 Innovations in the Mining Industry

Over the past years, sliding productivity and spiralling costs in the mining industry has

Top 4 Challenges Facing The Mining Industry

The mining industry is still recalibrating to a set of strong headwinds after the

How GroundHog SIC Helps Miners Meet Daily Production Targets

With profits down, the mining industry has shifted its focus towards improving productivity in

5 Recommendations for Successful Digital Transformation in Mining

According to a report by the World Economic Forum, digitalization in the mining industry

Improve Productivity With Digital Fleet Management System

Mining is a complex business that involves management of a large fleet of vehicles

5 Ways IoT Drives Innovation in Mining

As a number of asset-centric industries continue to leverage IoT to drive business performance

Top 5 Technology Innovations in the Mining Industry

The influx of an array of new technologies and digital innovations in the mining

7 Pitfalls Driving The Digital Disconnect in Mining

In a challenging market, mining companies are focused on driving productivity improvements that can

Digital Innovations in Mining That Are Set To Revolutionize The Industry – Part 1

During the mining supercycle, productivity fell to its lowest in more than 30 years.

Digital Innovations in Mining – The Digitally Connected Workforce

In part 1 of this series, we looked at advances in automation and robotics

Digital Innovations in Mining – Intelligence and Analytics in The Mining Industry

In part 1 and part 2 of this series, we looked at advances in

Meet Mining Production Targets with GroundHog Fleet Management System

Meet Mining Production Targets with GroundHog Fleet Management System GroundHog FMS is a comprehensive

Infographic: 7 Factors Driving The Digital Disconnect in Mining

EY’s global report ‘The digital disconnect: problem or pathway?’ points out that digital advances

5 Reasons Miners Must Digitize Paper-Based Forms

Digital transformation is high on the agenda of mining companies that seek to improve

The Connectivity Challenge in Mining

As the digital mine becomes a reality, there is an increasing dependence on hardware,

Digital Transformation in Legacy Industries

The digital transformation of mining companies is seen as a business imperative today –

The Need to Digitize Conventional Maintenance in Mining

In an asset-intensive industry like mining, equipment availability plays an integral role in meeting

Infographic: 5 Reasons Why We Should Move to Digital Forms In Mining

An essential step towards digitizing mining operations is moving from paper-based forms to digital

Getting Started With a Digital Short Interval Control System in Mining

As we explained in an earlier post, Short Interval Control (or SIC) is a

TOP 5 SAFETY INNOVATIONS IN MINING

Underground mines are hazardous environments, potentially exposing workers to a range of health and

MSHA’s New Workplace Exam Rule a Perfect Place to Start Mine’s Digital Transformation

With the rule has gone into effect on June 2nd, 2018 the US mining

To Stay MSHA-Compliant, Go Digital

MSHA’s Mining Updates on Workplace Examination Rules June 2, 2018, was a big day

3 Benefits GroundHog FMS Brings to Mining Fleet Maintenance

Mining is one of the most capital-intensive industries in the world, requiring millions of

Wi-Fi in Underground Mines Using Peer-to-Peer Networks

Over the last decade, mining productivity has been on a steady decline. The industry

How Mines Can Go Digital, One Byte at a Time

Market volatility and cost pressures in the mining industry underscore the critical need for

The 4 Factors That Make or Break a Fleet Management System

Not all fleet management systems are created equal – not by a longshot. Selecting

Top 8 Reasons Mines Must Connect Workers

A common misconception about digital deployment world is that it erodes job functions. In

The Holy Grail for Mining: Mine the Ore AND the Data

A new paradigm is emerging to confront a critical business challenge: how to access

GroundHog FMS Enhances REMOTE Capability to Improve Mining Efficiency

GroundHog FMS, which already cuts the operating costs of mines by 15%, has been

GroundHog joins the Amazon AWS Partner Network

GroundHog, the leading provider of apps, software, and services for digitizing operations and safety

Five Reasons Mines Should be Using Short Interval Control

It is 2019, competition in the mining industry is hotter than ever. As a

Building the Quarries of Tomorrow, Today

Quarries have been in use for thousands of years. However, in principle, they haven’t

A Connected Miner is an Efficient Miner

The miners of a hundred years ago would be shocked to see the technology

How quarryHog Helps Your Quarry Meet Daily Production Targets

Quarry managers work incredibly hard. The stress of meeting daily production targets can often

Short Interval Control Means Continuous Improvement for Mines

There isn’t a magic piece of software that can change the past and they’re

The Three Reasons quarryHog should be in your Quarry

quarryHog, rapidBizApps latest software, is a mobile fleet management system optimized for quarries. Designed

The Mining Industry’s Technology Adoption Hurdle

The mining industry is heading into uncharted territory. New technology is emerging left and

Improving OEE in Underground Mines with Digital Short Interval Control

When it comes to OEE, mining is well behind other industries that have somewhat

GroundHog EHS Takes The Headache Out of Health and Safety Audit Paperwork

Everyone can agree that safety is a top priority in mines. However, MHSA’s record

Three Change Management Strategies to Bring Mines Into the Digital Age

Change in the mining industry is inevitable. In order to turn change to progress,

How To Ensure Your Sand Mine Profits Continually Improve

Making money mining sand is tricky, but with the right approach, it is manageable.

Digital Transformation is About More Than Just Technology

Digital transformation is a top concern for many executives today. The promise of increased

How Sand Mines Should Be Capitalizing on the Shale Revolution

The American ‘Shale Revolution’ presents sand mines with a unique opportunity to grow profits

Three Benefits of a Network Connected Quarry

With the US oil and gas industry booming, now is a great time to

The Biggest Questions in The Frac Sand Industry Today

With the US oil and gas industry booming, now is a great time to

Low Cost Strategy for Quarry Managers to comply with MSHA Regulations

As a quarry manager, there are two constant pressures. Keeping costs at a minimum

The Importance of Good Data in Quarries

The most important thing a quarry can do is measure. Measure everything. Thorough, accurate

Simple Strategies to Optimize Haulage and Cycle Times Without Breaking the Bank

One of the easiest ways a quarry can boost its productivity is optimization of

Conducting Workplace Inspections – GroundHog EHS Series

Regular, proper workplace inspections are a cornerstone to a safe mine. While there is

Three Tips for Getting the Most out of your Mining Equipment

At the center of every successful mining operation is an arsenal of good equipment.

Perfoming a Site Safety Walk – GroundHog EHS Series

A safety walk is an essential part of any mine’s inspection routine. However, conducting

Performing a Conveyor Inspection – GroundHog EHS Series

Conveyor devices aren’t cheap and skimping on proper maintenance is just asking to lose

Three Mistakes You Don’t Want to Make During a Digital Transformation

In the not so distant future, companies will be forced to make a decision;

Conducting an Equipment Inspection – GroundHog EHS Series

To wrap up our GroundHog EHS series, we’ll be sharing some of our tips

GroundHog FMS OpsCenter – Reflect

Reflect is a proprietary GroundHog FMS infrastructure that allows Supervisors and Dispatchers at the

GroundHog FMS OpsCenter – Replay

Replay is a feature in the GroundHog FMS OpsCenter. It allows supervisors to see

GroundHog FMS OpsCenter – Rhythm

Rhythm provides supervisors with a simple interface to track when each tablet has been

Opinion: Tech Like SIC is The Only Way The Mining Industry Can Continue to Grow

The unfortunate reality of mining is that the heydays have passed. That may sound

Opinion: Short Interval Control is The Future of Quarries

There are many articles, both on this page and across the internet detailing why

Opinion: Not Digitizing Certificate Management isn’t just Inefficient, It’s Inviting Trouble

It isn’t very easy to work in health and safety. However, that doesn’t mean

Safety Directors Are Using GroundHog LMS. You Should Too.

More and more safety directors are ditching the stone age of certificate and permit

3 Reasons Safety Managers Should Use GroundHog LMS, Not Paper.

For the few H&S managers still managing certs and training on paper. It’s time

Introducing GroundHog EHS 3.8.0 Update

San Jose, California July 16, 2019: GroundHog EHS is a digital inspection app built

How to Keep Mining Intensity High and LOM Low

Mines work hard to keep their intensity high, which in turn allows them to

How to Empower Decision Making with Validated Data in Real Time

First line task coordinators need to be able to make informed decisions. However that

How to Capture and Use Data Effectively in Mines

The most important thing a mine can do is measure. Measure everything. Thorough, accurate

The One Tool Every Mine Needs for Their Task Scheduling and Tracking

Scheduling is hard, it’s even harder when you’re doing it for a mine full

How to Do it Right: Planning, Scheduling, Executing and Monitoring

Some of the most important tasks in a mine are planning, scheduling, executing and

The Software You Need to Get the Most out of Your Equipment

Mining equipment is a huge investment. If you’re going to drop that kind of

Three Ways to Track Equipment Data and Consumables

Tracking equipment data and consumables is a key part of mining. Mining cannot occur

3 Reasons Why Your Mine Needs Better Analytics

Data. Is. Everything. How you get it, how you use it. In mining, good

How to Capture and Use Data Effectively in Mines

The most important thing a mine can do is measure. Measure everything. Thorough, accurate

How to Empower Decision Making with Validated Data in Real Time

First line task coordinators need to be able to make informed decisions, however that

How to Do it Right: Operations Management

Operations management, like many other aspects of mining. Get vastly more difficult as you

3 Reasons Why Your Fleet Management System Needs Mobile Support

Fleet management systems are the single best way to boost your mine’s production. Not

How to Keep Delays from Hurting Productivity

There will be delays every once in a while, no matter how well you

How to Support a Multi-Skilled Workforce in Your Mine

One of the great challenges of running a mine can be the task of

How to Do it Right: Maintenance Management

There is a right way and a wrong way to manage maintenance in the

The Software You Need for a Safer Mine

Safety is everything in the mining world. Everyone wants to get home safe after

Developing Inexperienced Personnel in Your Mine

Hiring for a mine isn’t always easy, this is especially true given the remote

How To Do It Right: High Productivity with Low Crew Availability

We’d all like to have 100% crew availability 100% of the time. That’s never

How to Do it Right: Managing Labour Performance

Managing labour performance can be quite tricky and there is absolutely a right way

Here’s How to Boost Industrial Safety and Avoid OSHA Fines.

Industrial safety is at the front of every plant managers mind. OSHA fines are

5 Ways People Track Their 5000-23s: #2 Folders/Binders

The second method commonly used to track 5000-23s is more an evolution of the

5 Ways People Track Their 5000-23s: #3 Excel + Paper

As mining companies begin to shift away from paper forms of 5000-23 management they

5 WAYS PEOPLE TRACK THEIR 5000-23S: #4 EXCEL + PICTURES + PAPER

One step further than Excel and paper as a 5000-23 management solution is the

5 Ways People Track Their 5000-23s: #5 GroundHog LMS

After struggling with all the previously discussed “solutions” for 5000-23 management, it is inevitable

3 Reasons Safety Managers Should Ditch Excel, for GroundHog LMS.

Being a safety manager isn’t easy, but it’s even worse if you’re trying to

Task training doesn’t have to be as hard as you’re making it. Here’s why

Task training in mines can be a massive headache for health & safety managers,

How a Dime a Day Could Revolutionize Your Task Training

Managing your task training on paper or on Excel is cheap. However, fines from

GroundHog install at Underground Gold Mine in Nevada

Deployment Model for Site: Underground SIC, Fleet Management System, RTLS and Maintenance Management System