Deployment Model for Site: Mine Control (Dispatch) Mode

Site Information

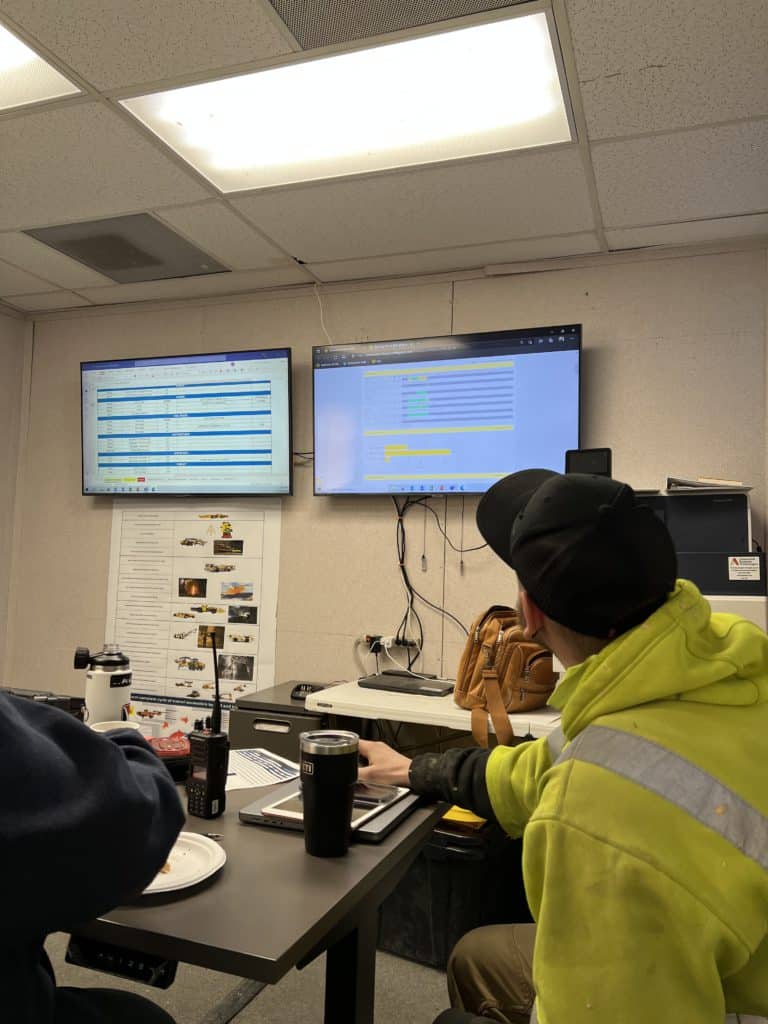

Cementation USA deployed GroundHog’s flagship OpsCenter platform to use Short Interval Control and manage Dispatch operations to increase productivity and safety.

Production Operations Management – Pre-GroundHog

The site primarily used a combination of Excel and paper based processes (daily logs / PLOD sheets) to capture production data. These Excel sheets were then used to create pass-down sheets that were then distributed to the crew during lineout.

Implementation Phase 1: Site survey

During the site survey the project team spent 3 days observing and documenting the current process, including:

- Daily Logs and reports

- Pre-shift meeting protocols

- Call signs

- Excel tracking sheets

- Interviews with Shift Supervisors, Operators, and Maintenance Supervisors

- Project Manager and Mine Manager

Implementation Phase 2: Data Import Templates

During phase 2, GroundHog worked closely with the site project team to transform all their Excel files to a format used to easily import data into the GroundHog OpsCenter platform. Imported data included:

- Names of all the mining locations (ramps, headings, stopes, muckbays, etc)

- Names, Makes and Models, and Capacities of all the primary and auxiliary equipment

- Names, roles, skillsets, and safety training documents of all miners, supervisors, geologists, and managers

- Material types, and grades

- Consumables types and quantities

Implementation Phase 3: Staging server and Training

The GroundHog Customer Success team installed and configured a staging server (pre-production) on a secure GroundHog AWS Cloud. The team also imported all resources related information. The Customer Success team worked with the site’s Continuous Improvement Team to configure the following:

- Customizing the Time Utilization Model to match the mine’s TUM template

- Mining Cycle templates (drill, powder-load, blast, muck, bolt, shotcrete, etc) based on heading / stope sizes

- Setting up sizes of headings, stopes, etc

- Updating the status of each heading, stope, etc.

- Updating material inventory

- Configuring various types of consumables used

- Configuring shift start times, etd times, etc

- Uploading mine maps

Phase 4: Dry Runs and SOP Document Creation

After training Dispatch/Mine Control, we did a few hours of dry-runs on all the following activity types:

- Shift Planning

- Jumbo operations

- LHD/Bogger operations

- Bolter related operations

- Haul truck related operations

- Construction relation operations

- Equipment up / down / delays / standbys

- Daily shift-end report (Daily Physicals)

- Safety logs

- Nncident reports

- Near miss reports

- Stop and correct logs

Based the experience during the dry-runs, the team created a first version of the Mine Control Standard Operating Procedures

Phase 5: Go live and Customer Care

Once the site went live, the Customer Care team actively participated during shift-handoffs and for about an hour after work started at the face, until Mine Control felt confident enough to run the show by themselves. The Customer Care team did periodic check-ins with Mine Control throughout the shift for the next two weeks.

Phase 6: Transition to Support

After 2 full crew rotations (4 weeks), the site transitioned from Customer Care to Customer Support.

Do Follow our LinkedIn Newsletters-

https://www.linkedin.com/newsletters/mine-digitization-automation-6924713123673235456/

Read our blogs-https://groundhogapps.com/groundhog-blog/