California, USA – GroundHog, the premier Mine Digitization and Automation platform, proudly announces a significant enhancement to its Telemetry offering. With the growing need for precise payload information, GroundHog has upgraded its Telemetry system to collect and report comprehensive payload data seamlessly via the Onboard Telematics with telemetry live feed.

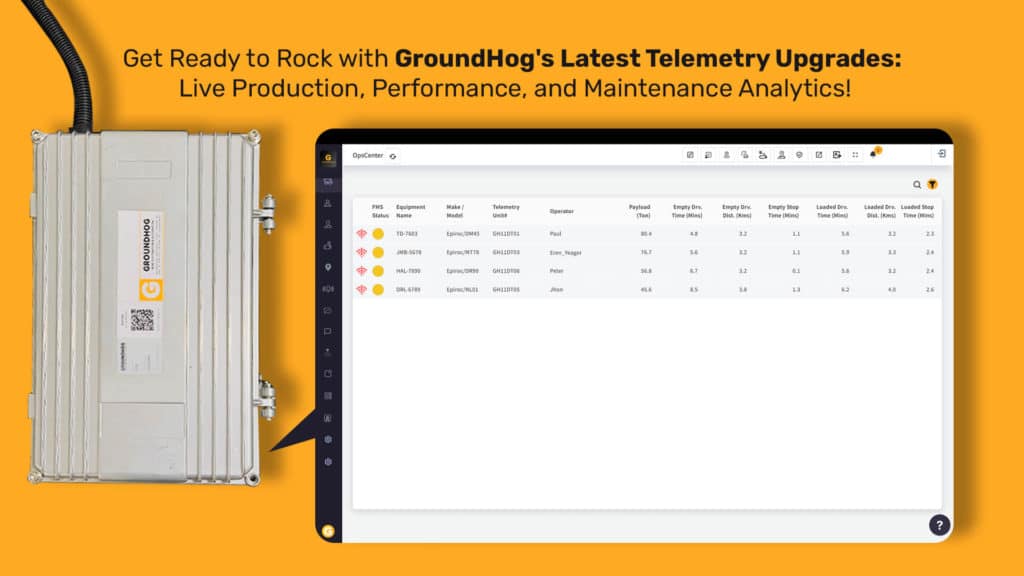

This was accomplished by the GroundHog Advanced Technology Group based in Perth, Australia. The group has successfully deployed an in-house engineered hardware solution that links both the onboard and live telemetry diagnostics ports; this includes the onboard computer systems. This seamlessly transmits into GroundHog’s Fleet Management System, and subsequently, GroundHog OpsCenter processes this data, presenting it in a user-friendly format.

GroundHog’s previous generation Telemetry solution already captures engine hours, data from temperature and pressure sensors, and fault codes. With this new enhancement, the dataset now will comprise all critical information such as Payload, Road Conditions, Event Data, Fuel Usage, and much, much more.

According to Todd Pearce, Managing Director for Australia at GroundHog, “Telemetry data plays an important role in the mining industry, mainly in the Australian market, primarily focusing on payload information that enhances operational efficiency, performance, and cost-effectiveness. Leveraging this data not only allows for real-time payload monitoring but also provides the ability to do in-depth analyses, encompassing historical payload trends, assessments of actual Vs expected, and other performance metrics.”

This integration of GroundHog’s software capability extends to machines from industry leaders such as Sandvik, Epiroc, Komatsu, CAT, Liebherr, and Hitachi, and when integrated and leveraged with a Wi-Fi network connectivity, the results can be seen in real-time. Interested users can activate this functionality by acquiring the dedicated hardware unit that establishes a direct connection between the machine and the cloud. Notably, this feature significantly reduces the potential for human error, as data can now be obtained directly without requiring manual input from operators. GroundHog’s Telemetry data integration is pivotal in enhancing operational efficiency and precision in the mining industry.

About GroundHog:

GroundHog is a mine digitization and automation platform, an innovative industry leader providing advanced digitization tools. Their operational and safety solutions simplify complex workflows by applying technology to arduous processes, specializing in short-interval control, fleet management, and environmental, health, and safety tools.

Their mission is to see every mine digitized to increase profitability by achieving higher production rates at a lower cost per ton without sacrificing safety. GroundHog’s solutions help to eliminate silos through streamlined collaboration tools so operations and safety teams can spend their time where it matters the most.

GroundHog’s products and services were developed and tested by some of the finest hard-hat folks from the mines of Nevada, Alaska, Australia, and India and are now present globally.

Visit www.groundhogapps.com for more information.

###Media contact: Email: getStuffDone@groundhogapps.com