Introduction

Welcome to our comprehensive guide on RTLS in underground mines. In this article, we will explore how Real-Time Location Systems (RTLS) are revolutionizing safety and efficiency in the mining industry. RTLS technology plays a crucial role in improving operational visibility, optimizing resource utilization, and enhancing worker safety in underground mining operations.

Mining is a challenging industry with numerous hazards and risks. The underground environment poses unique challenges that demand innovative solutions to ensure the well-being of workers and the efficient extraction of valuable resources. RTLS technology provides real-time tracking and monitoring capabilities, enabling mine operators to mitigate risks, streamline operations, and improve overall productivity.

So, let’s dive deep into the world of RTLS and uncover how it transforms underground mining operations to achieve unprecedented levels of safety and efficiency. Read more about GroundHog’s RTLS system here.

RTLS in Underground Mines: Enhancing Safety

Safety is paramount in any mining operation, especially in underground mines where workers face a multitude of risks. RTLS technology plays a vital role in enhancing safety measures by providing real-time location information and enabling rapid emergency response. Let’s explore some key aspects of how RTLS improves safety:

Improved Worker Tracking and Monitoring

RTLS enables precise tracking and monitoring of workers in underground mines, ensuring their safety and well-being. By equipping miners with wearable RTLS tags or integrating the technology into their personal protective equipment (PPE), their locations can be accurately determined in real time. This information is invaluable in the event of an emergency, allowing rescue teams to quickly locate and assist workers in distress.

Proactive Hazard Mitigation

RTLS systems allow for the proactive identification and mitigation of potential hazards in underground mines. By collecting real-time data on worker movements, equipment utilization, and environmental conditions, operators can detect unsafe conditions or behaviors promptly. This enables them to take proactive measures to eliminate or minimize risks before accidents occur.

Emergency Response and Evacuation

In the event of an emergency, such as a collapse or a gas leak, RTLS technology facilitates rapid emergency response and evacuation procedures. By accurately tracking the location of workers, rescue teams can swiftly reach affected areas and carry out rescue operations efficiently. The real-time visibility provided by RTLS enhances the chances of successful rescue and minimizes potential casualties.

Geofencing and Restricted Area Monitoring

RTLS systems utilize geofencing capabilities to establish virtual boundaries and monitor access to restricted areas within the mine. If a worker or vehicle enters a restricted zone, an alert is triggered, ensuring compliance with safety protocols and preventing unauthorized access to hazardous areas. Geofencing also assists in preventing accidents by restricting entry into high-risk zones, such as unstable rock formations or areas prone to gas leaks.

Fall Detection and Man-Down Alerts

Accidental falls and injuries are common risks in underground mines. RTLS technology can detect falls and automatically trigger alerts to notify nearby workers or the control center. Man-down alerts ensure that immediate assistance can be provided to the injured worker, potentially saving lives and minimizing the severity of injuries.

Training and Safety Compliance

RTLS systems also contribute to training and safety compliance efforts in underground mines. By analyzing the data collected from the system, operators can identify patterns, pinpoint areas of concern, and develop targeted training programs to address specific safety issues. This data-driven approach enhances safety awareness and fosters a culture of continuous improvement in the mining workforce.

RTLS in Underground Mines: Optimizing Efficiency

In addition to improving safety, RTLS technology brings substantial benefits in terms of optimizing efficiency and productivity in underground mines. Let’s explore some key aspects of how RTLS enhances operational efficiency:

Equipment Tracking and Utilization

RTLS technology enables accurate tracking and monitoring of mining equipment, including vehicles, machinery, and tools. By attaching RTLS tags to equipment, operators can gain real-time visibility into their location, utilization, and performance. This information facilitates efficient equipment allocation, preventive maintenance scheduling, and reduces equipment downtime, ultimately maximizing productivity.

Personnel and Resource Management

RTLS systems provide insights into personnel and resource management, streamlining workflows and optimizing productivity. By analyzing real-time data on worker movements, operators can identify bottlenecks, improve task allocation, and enhance overall operational efficiency. Additionally, the data collected from RTLS systems can assist in resource planning, ensuring the availability of critical supplies and materials when and where they are needed.

Asset Inventory and Tracking

Maintaining an accurate inventory of assets is essential for efficient mining operations. RTLS technology enables real-time asset tracking, eliminating manual inventory management processes and reducing human error. By automatically monitoring the location and movement of assets, mine operators can quickly locate equipment or supplies, reducing search times and improving operational efficiency.

Predictive Maintenance

RTLS systems can be integrated with predictive maintenance solutions to optimize equipment maintenance schedules. By continuously monitoring equipment performance and collecting data on factors such as temperature, vibration, and usage, operators can identify potential failures or maintenance needs before they occur. This proactive approach minimizes unplanned downtime, extends equipment lifespan, and reduces maintenance costs.

Workflow Optimization

RTLS technology provides valuable insights into worker movements and interactions, enabling mine operators to optimize workflows and minimize inefficiencies. By analyzing the data collected, operators can identify areas where workflow bottlenecks occur, implement process improvements, and optimize task sequencing. This streamlines operations, reduces idle time, and increases overall productivity.

Energy and Environmental Efficiency

RTLS systems can contribute to energy and environmental efficiency in underground mines. By monitoring and analyzing energy consumption patterns, operators can identify opportunities for energy optimization and implement measures to reduce waste. Additionally, RTLS technology can assist in monitoring and controlling ventilation systems, ensuring optimal air quality and minimizing energy consumption without compromising worker safety.

FAQs about RTLS in Underground Mines

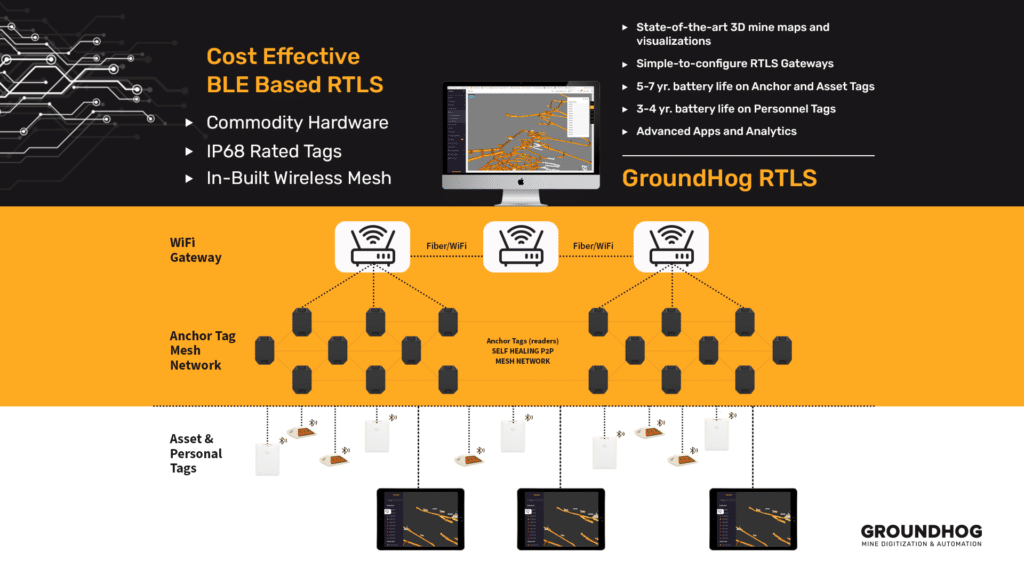

- What is RTLS, and how does it work in underground mines?RTLS stands for Real-Time Location System, which uses various technologies such as RFID, Bluetooth, or Wi-Fi to track and locate assets or personnel in real time. In underground mines, RTLS utilizes a network of fixed reference points and wearable tags to provide accurate positioning and tracking information.

- Why is RTLS important in underground mining operations?RTLS is crucial in underground mining operations due to its ability to enhance safety measures, improve operational efficiency, and optimize resource utilization. It provides real-time visibility into worker locations, enables rapid emergency response, streamlines equipment tracking, and facilitates workflow optimization.

- What are the key components of an RTLS system in underground mines?An RTLS system in underground mines typically consists of reference points, wireless infrastructure, wearable tags, and software applications. The reference points serve as fixed anchors, while the wireless infrastructure provides connectivity. Wearable tags are attached to personnel or assets, and the software applications process the location data and provide real-time insights.

- How does RTLS improve safety in underground mines?RTLS improves safety in underground mines by enabling precise worker tracking, proactive hazard mitigation, rapid emergency response, geofencing, fall detection, and man-down alerts. These features help prevent accidents, enhance rescue operations, and ensure compliance with safety protocols.

- Can RTLS technology be integrated with existing mine management systems?Yes, RTLS technology can be seamlessly integrated with existing mine management systems. The location data collected by the RTLS system can be integrated with other operational data, such as maintenance schedules, production targets, and safety protocols. This integration provides a holistic view of mining operations and enables better decision-making.

- Are there any privacy concerns associated with RTLS in underground mines?Privacy concerns related to RTLS in underground mines can be addressed through proper implementation and clear communication. It is essential to establish policies and guidelines regarding the collection and use of location data, ensuring the privacy rights of workers are respected. Transparency and open dialogue between mine operators and workers are key to addressing privacy concerns effectively.

Conclusion

Real-Time Location Systems (RTLS) are revolutionizing the mining industry by enhancing safety measures and optimizing operational efficiency in underground mines. The ability to track and monitor workers and assets in real time enables mine operators to mitigate risks, improve emergency response, streamline workflows, and maximize resource utilization. RTLS technology has become an indispensable tool for ensuring worker safety, preventing accidents, and achieving unprecedented levels of efficiency in underground mining operations.

As the mining industry continues to evolve, RTLS will play an increasingly significant role in driving safety, productivity, and sustainability. Embracing this technology empowers mining companies to navigate the challenges of the underground environment while safeguarding their most valuable assets—their workers.