Benefits of Purpose-Built Remote Monitoring Technologies As technology continues to advance the way mines operate in real time, operations are expanding into even more remote and challenging environments, and deeper below the earth’s surface. Sometimes far removed from access to nearby infrastructure, this shift continues to make it even more essential to adopt remote monitoring systems so that you have insight where it would otherwise require you to be on-site around the clock. Today we explore how remote monitoring technologies are providing game-changing advancements in safety, productivity, and sustainability, amongst others.

Enhanced Safety Measures

Safety is always of paramount importance. Heavy equipment, shifting environments, and rugged conditions join forces to present unique hazards. As technology continues to offer new frontiers, quicker responses and fewer accidents are happening. IoT sensors and wearable devices take into account fatigue management by monitoring workers’ vital signs to detect potential health risks or hazards like toxic gases or dangerous temperatures. With real-time alerts and remote monitoring technologies, no matter where you are, your team can respond quickly to pending incidents and mitigate risks remotely.

An example of how GroundHog helps is below:

A person underground can be alerted to the nearest rescue chamber using RTLS systems.

Real-Time Equipment Monitoring

You rely on the availability of your mobile fleet, as well as fixed assets to meet productivity targets, and no doubt you’re familiar with how directly equipment failure equates to productivity loss. Purpose-built remote monitoring operational technologies help prevent unplanned downtime with real-time vehicle health features. When vehicle health data is available remotely, your team can move into predictive maintenance practices, identifying issues before they escalate, and allowing you to schedule maintenance proactively during planned downtime. This reduces unplanned shutdowns and increases overall equipment efficiency.

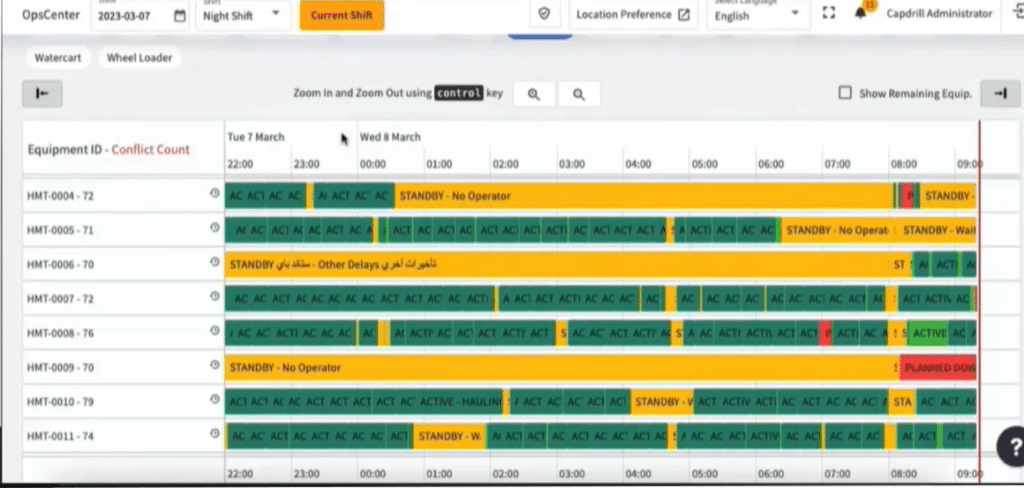

An example of real-time monitoring of equipment and their trips from a remote operations center in an open pit mine.

An example of remote real-time monitoring of downs and delays captured by the operator in the field.

Optimal Resource Management

Mining operations often consume large amounts of resources, including water, electricity, and fuel. Purpose-built technologies give your team valuable insights into resource consumption patterns, enabling efficient resource management. With remote monitoring, you can identify and address wastage, optimize resource usage, and implement eco-friendly practices. Sustainable measures let you reduce operational costs and demonstrate your mine’s commitment to environmental responsibility and preservation.

Improved Environmental Compliance

Environmental compliance is a top priority, and remote monitoring technologies enable you to track and assess the environmental impacts of your operations. Continuous monitoring of your mine site with data analytics gives the right people access to real-time environmental data and historical records, streamlining inspections and audits. Regulatory compliance is significantly streamlined with remote monitoring tools.

Efficient Inventory Management

Mining operations manage vast inventories of materials, and it gets complicated fast. Purpose-built technologies simplify this by giving you tracking for your inventory levels remotely, streamlining supply chain management. Real-time visibility into inventory levels lets you maintain the proper materials, preventing stockouts or overstocking situations. Automated inventory management reduces manual errors and ensures seamless production processes, ultimately leading to improved productivity and cost savings.

Remote Site Surveillance

Due to the remote nature of mining operations, manual surveillance is challenging and costly. Purpose-built technologies, such as drones and remote cameras, enable efficient site surveillance from a centralized control center so you can monitor vast areas with high resolution, providing real-time video feeds and detailed imagery. Remote surveillance enhances security, detects unauthorized access, and helps prevent theft or vandalism, contributing to safer and more secure operations for you and your team.

Purpose-built remote monitoring operational technologies are revolutionizing the way you can monitor your site remotely. Enhanced safety measures, real-time equipment monitoring, optimal resource management, improved environmental compliance, efficient inventory management, and remote site surveillance are some of the key benefits of these technologies. By embracing operational technologies, mining companies enhance safety, productivity, and sustainability while also gaining a competitive edge in a dynamic and challenging industry.

As technology continues to advance, technology will undoubtedly evolve with even more innovative features and capabilities. Investing in cutting-edge solutions will help you and your team achieve higher levels of operational efficiency, cost-effectiveness, and environmental stewardship, further solidifying your mining company as responsible and successful industry leaders

. The GroundHog team is here to help.

Do Follow our LinkedIn Newsletters-

https://www.linkedin.com/newsletters/mine-digitization-automation-6924713123673235456/

Read our blogs-https://groundhogapps.com/groundhog-blog/