At GroundHog, we are committed to revolutionizing the way mines do their digital explosives inventory management using our MagLogs App. Our cutting-edge technology and innovative solutions provide a comprehensive system that ensures optimal efficiency, safety, and ensure MSHA and ATF compliance. In this article, we will delve into the key challenges faced by the industry and present our advanced approach to digital explosives inventory management, empowering mines and drill and blast contractors to outperform their competitors.

Introduction to Digital Explosives Inventory Management

Efficient management of digital explosives inventory is crucial for mining, construction, and other industries that rely on controlled explosions for various operations. Traditional inventory management methods often suffer from inaccuracies, delays, and safety concerns, leading to significant financial and operational repercussions. Most of these inventories are still managed on paper. However, by leveraging our state-of-the-art digital explosives inventory management system, these mine sites can overcome day-to-day challenges and streamline their operations.

Understanding the Challenges

1. Inaccurate Inventory Tracking

Traditional methods of inventory tracking often rely on manual data entry and paper-based systems, which are prone to errors, misplacement, and outdated information. These inaccuracies can lead to inefficient resource allocation, delays in operations, and potential safety hazards.

2. Compliance and Regulatory Issues

Strict regulations surround the storage and transportation of explosives, requiring businesses to maintain meticulous records and adhere to safety guidelines. Failure to comply with these regulations can result in hefty penalties, project delays, and reputational damage. It is crucial for businesses to have a robust inventory management system that ensures compliance at all times.

3. Operational Inefficiencies

Without an optimized inventory management system, businesses may struggle with inefficient workflows, redundant processes, and difficulties in forecasting future requirements. These inefficiencies can hinder productivity, increase costs, and prevent businesses from achieving their full potential.

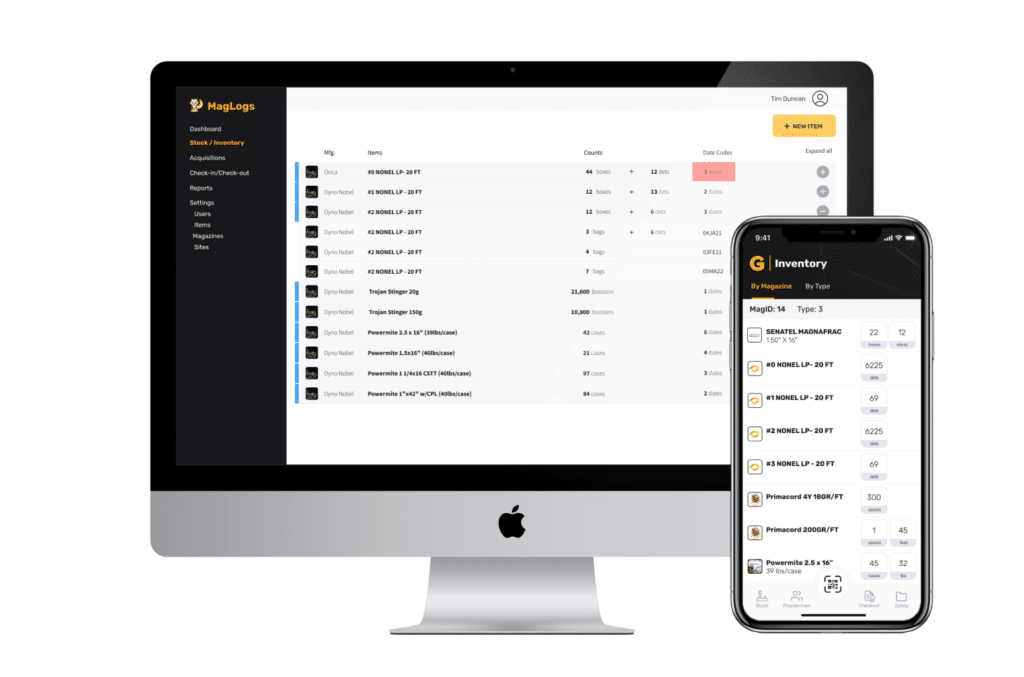

Our Advanced Solution: The Digital Explosives Inventory Management System

Our Digital Explosives Inventory Management System is a state-of-the-art software solution designed to address the specific challenges faced by businesses in the explosives industry. With its user-friendly interface, advanced features, and seamless integration capabilities, our system offers a holistic approach to inventory management, ensuring enhanced efficiency, accuracy, and compliance.

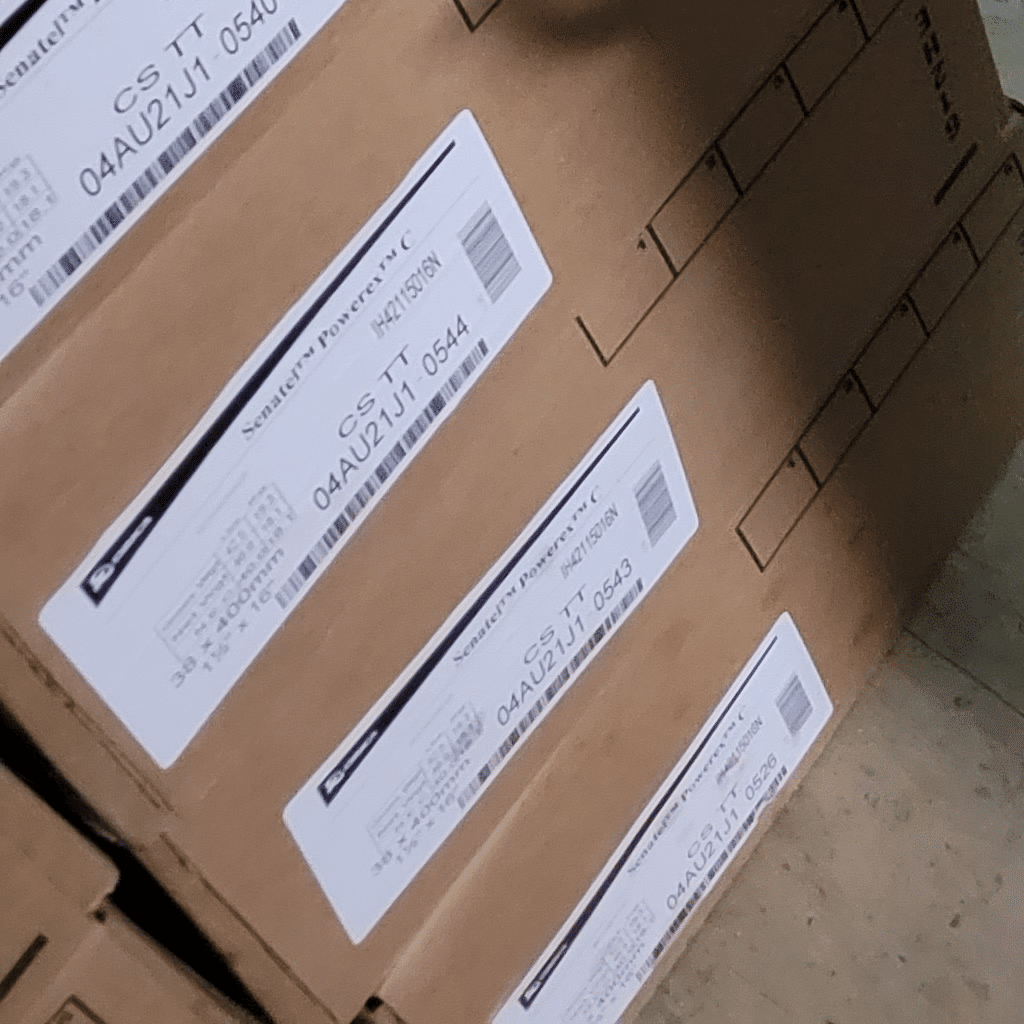

1. Real-time Inventory Tracking

Our system utilizes cutting-edge technologies such as RFID tagging, barcode scanning, and cloud-based data storage to enable real-time inventory tracking. By leveraging these technologies, businesses can achieve accurate and up-to-date information on their explosives inventory, minimizing errors and ensuring optimal resource allocation.

2. Regulatory Compliance Made Easy

With our system, businesses can effortlessly maintain compliance with industry regulations and safety guidelines. The software features automated record-keeping, document management, and audit trail functionalities, providing businesses with a centralized platform for maintaining regulatory compliance. This reduces the risk of penalties, project delays, and reputational harm.

3. Streamlined Operations and Improved Forecasting

Our system streamlines inventory management processes, eliminating redundant tasks and optimizing workflows. Through data analytics and predictive algorithms, businesses can gain valuable insights into inventory trends, consumption patterns, and future requirements. This empowers businesses to make informed decisions, reduce costs, and improve overall operational efficiency.

The Benefits of Our Digital Explosives Inventory Management System

1. Enhanced Safety and Risk Mitigation

By accurately tracking and managing explosives inventory, our system mitigates the risk of accidents, unauthorized access, and potential security breaches. This ensures a safe working environment and minimizes the likelihood of regulatory non-compliance.

2. Cost Reduction and Resource Optimization

With real-time inventory data and advanced analytics, businesses can optimize their resource allocation, minimize excess stock, and avoid production disruptions due to inventory shortages. This leads to significant cost savings and improved profitability.

3. Improved Productivity and Operational Efficiency

Our system automates manual inventory management tasks, allowing employees tofocus on more value-added activities. This enhances productivity and operational efficiency, enabling businesses to achieve higher output levels and meet project deadlines more effectively.

4. Data-Driven Decision Making

Through comprehensive reporting and data analytics capabilities, our system provides businesses with actionable insights to make informed decisions. By leveraging these insights, businesses can optimize inventory levels, streamline procurement processes, and identify areas for improvement.

Conclusion

Efficient management of digital explosives inventory is paramount for businesses in the mining, construction, and related industries. By adopting our state-of-the-art Digital Explosives Inventory Management System, businesses can overcome the challenges associated with traditional inventory management methods. With real-time tracking, regulatory compliance features, streamlined operations, and enhanced safety, our system empowers businesses to outperform their competitors and achieve greater efficiency and profitability.

To learn more about how our Digital Explosives Inventory Management System can transform your business, contact [OurCompany] today.