Change is the only constant. Nowhere is this axiom more fitting than in the rapidly evolving world of underground mining. As we forge ahead into the future, technological advancements continue to reshape the mining industry in fascinating ways. One of these is the evolving landscape of Underground Mining Fleet Management Systems. Let’s explore what the future holds for these systems and their potential to revolutionize the mining sector.

Future Underground Mining Fleet Management Systems will be tightly integrated with autonomous equipment

A Primer on Underground Mining Fleet Management Systems

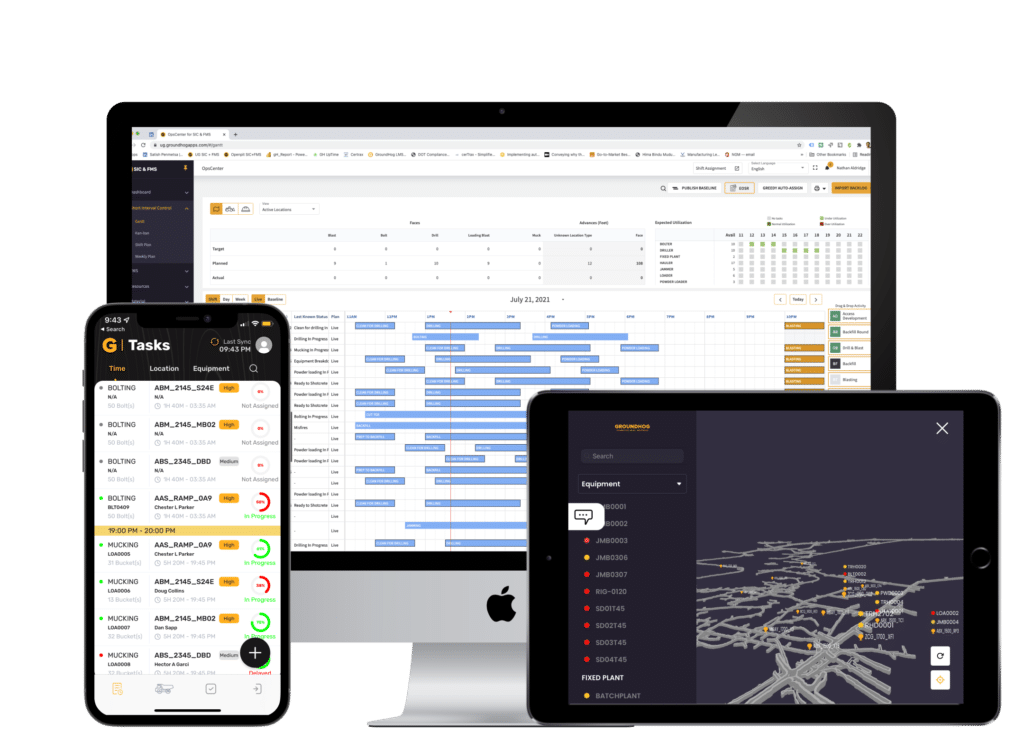

To comprehend the future, we must first understand the present. What exactly are these systems, and what role do they play in mining operations? In the simplest terms, underground mining fleet management systems are advanced software solutions used to track, schedule, and manage mining vehicles and equipment. Imagine if we could make every vehicle and piece of equipment smarter? That’s the essence of these systems. GroundHog is one of the leading Underground Fleet Management Systems in the world.

The Importance of Fleet Management in Mining

Without a doubt, fleet management plays a pivotal role in modern mining operations. It’s like the central nervous system of the entire mining operation, connecting all the parts and ensuring they function in harmony. Isn’t that fascinating? Not only do these systems streamline operations, but they also enhance safety and increase productivity – the lifeblood of any mining operation.

Future Trends in Underground Mining Fleet Management Systems

The future of mining fleet management systems is full of intriguing possibilities. As the mining industry continues to embrace digital transformation, we expect to see several emerging trends that could shape the future of these systems.

Increased Use of Artificial Intelligence and Machine Learning

Isn’t it fascinating how artificial intelligence and machine learning are transforming industries across the globe? Well, mining is no exception. Future fleet management systems will likely leverage AI and machine learning to predict equipment failures, optimize routes, and improve operational efficiency. Picture a mining operation where machines learn from their mistakes and improve over time. That’s the power of AI and machine learning.

Two companies that are on the bleeding edge of using AI in Underground Mines are:

Enhanced Connectivity and Real-time Data Analysis

In the future, underground mining fleet management systems will be more interconnected than ever, providing real-time data analysis. Can you imagine receiving instantaneous data about your fleet’s performance, safety statistics, and productivity metrics? This high level of connectivity and real-time data analysis will empower mining operations to make more informed decisions on the fly.

The Implications of these Future Trends

The future trends in fleet management systems will have profound implications for the mining industry. By leveraging AI, machine learning, and enhanced connectivity, mining companies can look forward to a future of increased efficiency, safety, and productivity.

Efficiency and Productivity Gains

Just picture it. Machines predicting their own breakdowns and optimizing their routes. Real-time data guiding decision-making. All of these factors culminate in remarkable efficiency and productivity gains. The future fleet management systems will not only save mining operations valuable time and resources but also boost their bottom lines.

Improved Safety Standards

Safety is paramount in any mining operation. With future fleet management systems providing real-time data and predictive analytics, safety standards are set to improve drastically. Imagine a world where potential hazards can be identified and mitigated before they pose a risk. This isn’t science fiction – it’s the promising reality of the future mining industry.

Conclusion

As we gaze into the future, the potential of underground mining fleet management systems is undeniable. Through artificial intelligence, machine learning, and enhanced connectivity, these systems will propel the mining industry into a new era of efficiency, productivity, and safety. So, are you ready for the future ofmining? It’s not just about the minerals we extract, but the innovative methods we use to get there. Indeed, the future looks bright, and these systems are set to light the way.

Frequently Asked Questions (FAQs)

1. What are underground mining fleet management systems? Underground mining fleet management systems are advanced software solutions used to track, schedule, and manage mining vehicles and equipment.

2. What role does fleet management play in mining operations? Fleet management acts as the central nervous system of mining operations, streamlining operations, enhancing safety, and boosting productivity.

3. How will AI and machine learning shape the future of fleet management systems? AI and machine learning will enable future fleet management systems to predict equipment failures, optimize routes, and enhance operational efficiency.

4. How will real-time data analysis impact mining operations? Real-time data analysis will provide mining operations with instantaneous data about fleet performance, safety statistics, and productivity metrics, aiding decision-making.

5. How will future fleet management systems affect safety standards in mining operations? By providing real-time data and predictive analytics, future fleet management systems will drastically improve safety standards by identifying and mitigating potential hazards.