Deployment Model for Site: Underground SIC, Fleet Management System, RTLS and Maintenance Management System

Site Information

GroundHog Deployed the OpsCenter for Short Interval Control, Fleet Management, RTLS for Automated Trip Counting and GroundHog’s Maintenance Management System. The site’s infrastructure such as WiFi was upgraded as part of their Digital Transformation initiative in 2016. The site primarily used a cut-and-fill mining method, and had just started Long Hole Open Stoping in a few zones.

Production Operations Management – Pre-GroundHog

The site had about 700 miners, and 15 supervisors.

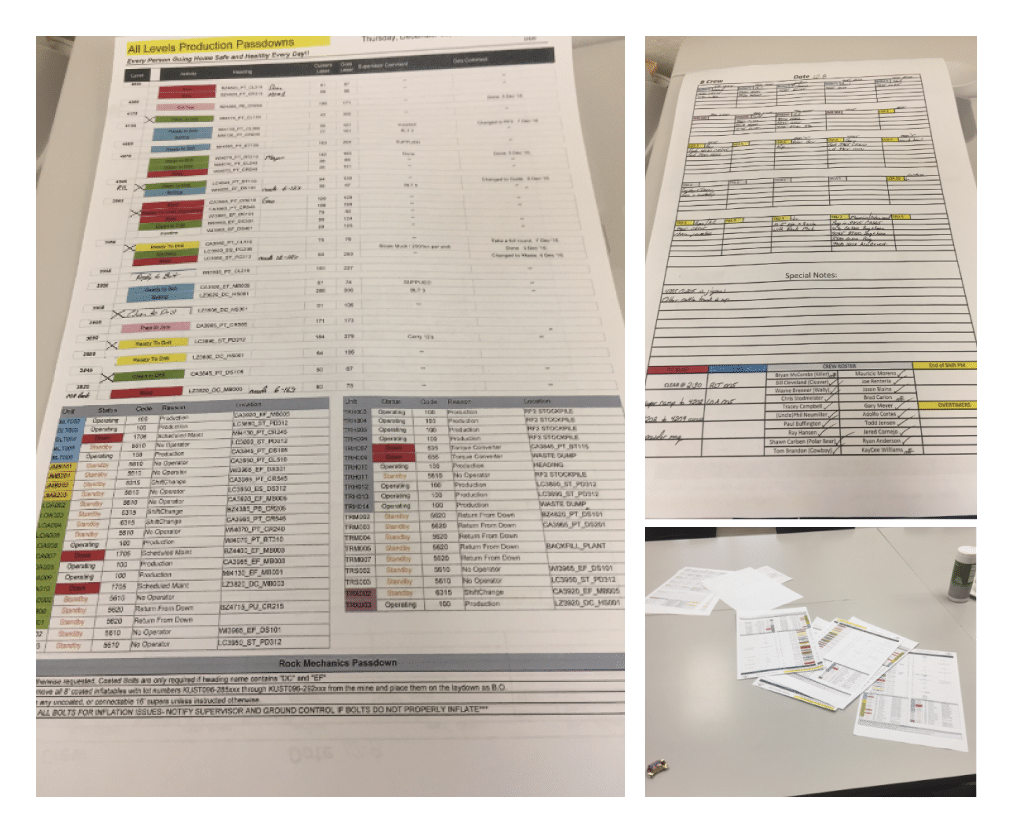

At the start of a shift, supervisors created pass-down sheets that included the stopes there were going to work on, and assigned eqiupment and operators to perform those work items. Production data was also recorded in these sheets.

The site was using a competitor product in a call-in dispatch only mode. While the competitor product had a tablet, the site team had many instances of data loss – especially from tablets that were working at the face in areas with no WiFi connectivity. Hence, the site had switched to a call-in dispatch mode.

In addition to calling in to dispatch, miners also recorded data on production cards. The miners also performed pre-start inspections and workplace exams on safety cards. At the end of the shift, these papers were handed back to supervisors who signed-off on them and gave to data-entry clerks that then cross-checked data with the data in the competitor product. Shift changes typically averaged about 55 minutes because of this labor intensive process.

The following data was captured as part of the production logs

- Face details, #trips and tonnage for mucking

- Face details, #holes and meters drilled for drilling

- Face Location and Rock Bolt Drilling meters for rock bolt drilling

- Face Location and #bolts fixed and meters grouted for rock bolt grouting

- Breakdowns

- Blast log and mis-fires

- Dumping details such as tonnage trips and buckets (when loaders re-mucked or dumped directly into an ore-pass)

Phase 1: Site survey

During the site survey, the project team spent 2 weeks observing and documenting the current process, including:

- End-of-Shift reporting

- Shift Allocation process

- Attendance process

- Pre-shift meeting protocols

- Daily Logs and reports

- Excel tracking sheets

- Interviews with Shift In Charge, Foreme, Operators, and Maintenance Supervisors

- Project Manager and Mine Manager

Data Entry and validation.

During phase 2, GroundHog worked with the site team to import initial data such as:

- Names of all the mining locations (faces, grizzly, Stockpiles, Crushers)

- Names, Makes and Models, and Capacities of all the primary and auxiliary equipment

- Names, roles, skill sets, and safety training documents of all miners, supervisors,foremen, operators and managers

- Material types, and grades

- Consumables types and quantities

Phase 2: Staging server and Training the Trainers

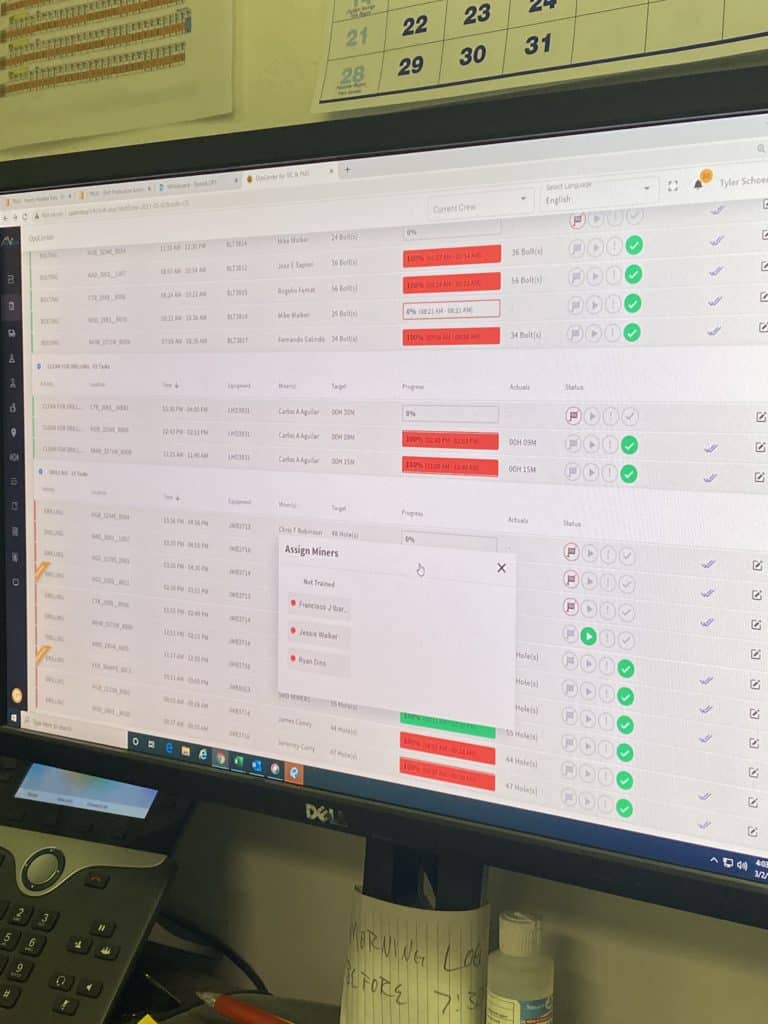

The GroundHog Customer Success team installed and configured a staging server (pre-production) on a secure GroundHog AWS Cloud. GroundHog team trained supervisors and dispatchers on using the Short Interval Control system to easily import data from their short term mine planning software into GroundHog. We also showed them how to easily create their shift plans using the easy-to-use drag-and-drop based GANTT scheduler.

The Customer Success team did a few dry-runs on all the following activity types:

- Shift Planning

- Hot-shift changeovers

- Drill operations

- Excavator operations

- Haul truck-related operations

- Auxiliary support operations (e.g. Scaling, etc)

- Equipment up / down / delays/standbys

- Daily shift-end report (Daily Physicals)

- Safety logs

- Incident reports

- Near miss reports

Based on the experience during the dry-runs, the team created the first version of the Mine Control Standard Operating Procedures. Separate templates for reports were created for LHDs, Haul Truck, and Jumbos. Custom report was built to provide a consolidated view to management after every shift.

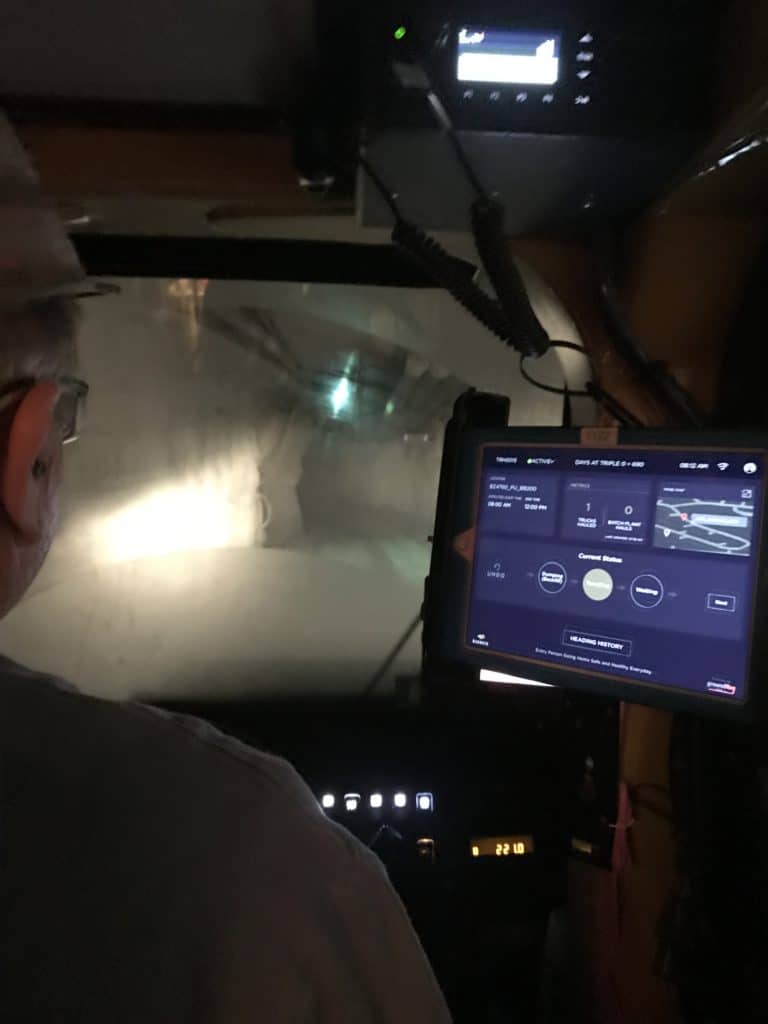

Once we trained operators on surface, we also did ride-alongs to train the operators:

Specific rooms were also created for these data entry operators.

Phase 3: Go live and Customer Care

For the first couple of weeks, Supervisors and Miners ran a parallel process using the old system and the new GroundHog system. The Supervisors and the GroundHog customer care team compared all data in the two systems, until the mine team was confident in the new process, and in the quality of the data. End-of-shift logs were reviewed by supervisors manually first before being sent to management by email. In week 3, end-of-shift reports were also sent automatically to mine management.

The Customer Care team actively participated during shift-handoffs and for about an hour after work started at the face, until Dispatch and Supervisors felt confident enough to run the show by themselves. The Customer Care team did periodic check-ins with Dispatch throughout the shift for the next two weeks.

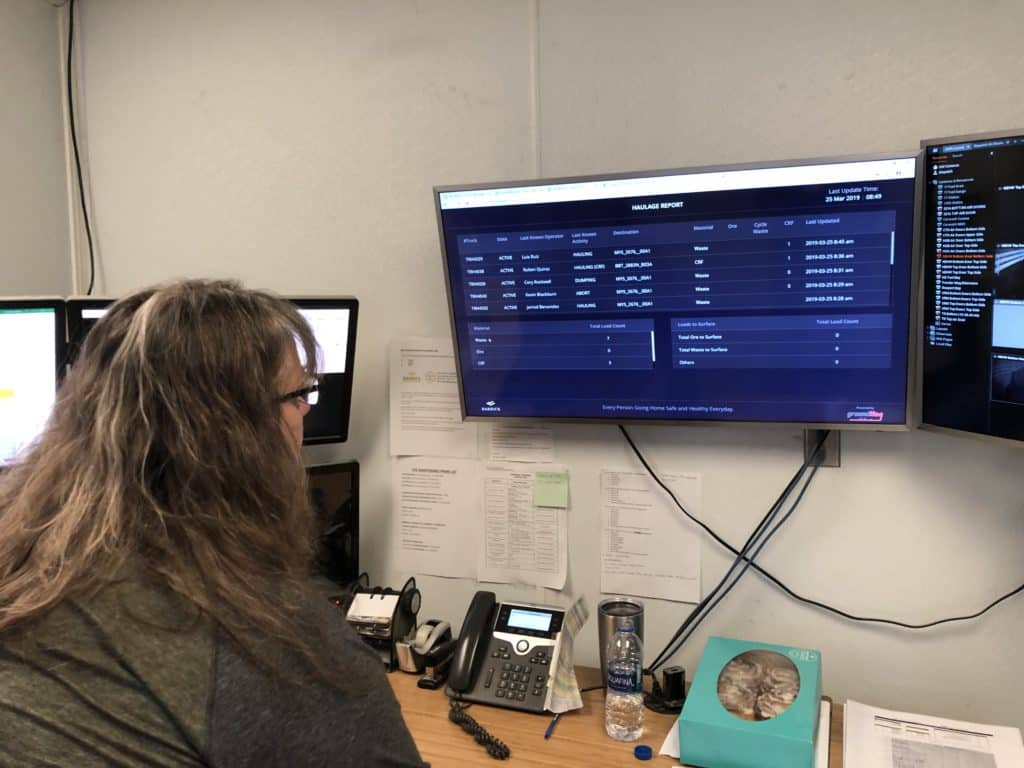

TVs were also installed for mine managers, supervisors, and mine managers to review status and allocation.

Transition to Support

After 2 full crew rotations (4 weeks), the site transitioned from Customer Care to Customer Support.

GroundHog’s support team has a standing meeting with the customer team to review the system, analyze data, seek customer feedback and make improvements to the product and process.