Diggers are the most essential equipment in an open pit mine. These giants in mining play a key role when it comes to operating efficiency. In recent years, the mining industry has seen a significant rise in adopting high-precision diggers and other technologies that aid high-precision digging. These innovative approaches have revolutionized mining operations, improving efficiency, reducing costs, and enhancing safety measures.

High-precision GPS is used in mining to maximize ore recovery and increase productivity safely and sustainably. High-precision digging is a powerful technique that helps minimize waste extraction and routes material correctly while reducing overall resource consumption. By accurately identifying mineral-rich areas and selectively extracting them, mining operations can optimize their productivity while minimizing their ecological footprint. This targeted approach is essential for maximizing ore recovery and increasing productivity in the mining industry.

Role of Technology in Precision Digging

Technology plays a critical role in implementing high-precision digging. Providing better and real-time feedback for better mine planning and ensuring better compliance with the plan is the first step in improving productivity. Technologies such as drones provide planners and decision-makers with a better understanding of the terrain.

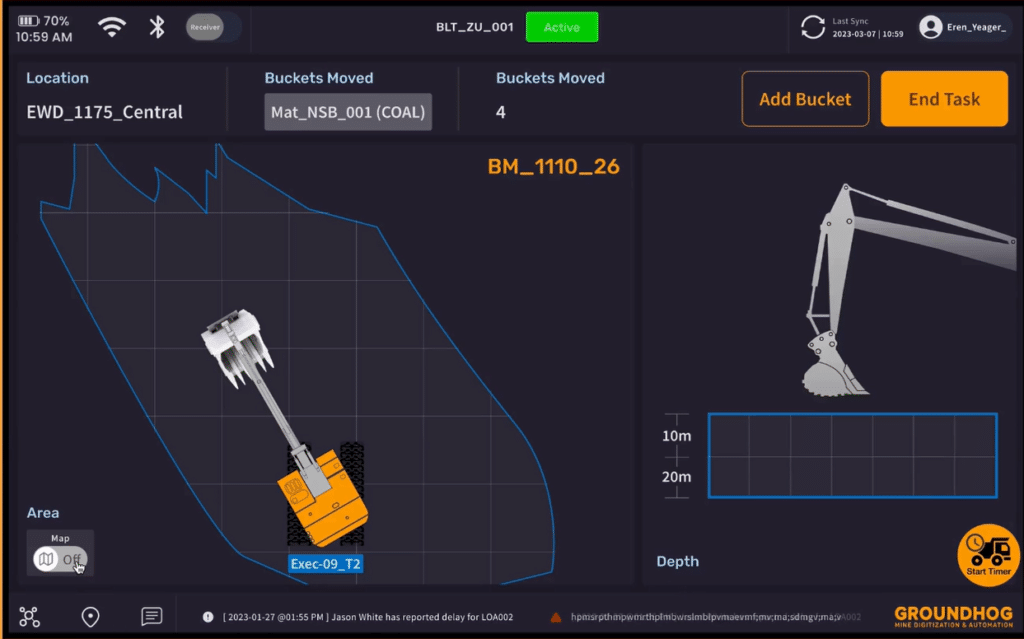

Highly sophisticated diggers with sensors integrated with high-precision GPS and GIS systems, data analytics, and machine learning help achieve high compliance with the plan during execution. Laser-guided diggers are a valuable asset that provides operators with a detailed 3D terrain model, allowing for accurate measurements and precise location data. This eliminates guesswork and minimizes the risk of human error.

High-precision GPS technology is one of the most notable advancements in diggers, redefining precision and accuracy. With high-precision GPS systems onboard, digger operators can navigate and control the machine with an unprecedented level of accuracy, almost to 2cm level accuracy. Satellite signals help pinpoint the digger’s exact location in real-time, integrating that information into the machine and the operator’s tablet for accuracy in digging and grading tasks.

In complex terrains with critical measurements and angles, diggers equipped with high-precision GPS can perform tasks with unmatched accuracy, ensuring that the ore grade dug out aligns perfectly with the plan. This level of high precision improves the quality of the digger’s work, reduces material waste and costs, and saves time. The operator is also alerted when digging below the bench height, reducing the need for the Grader to level the bench continuously and improving traffic flow and safety.

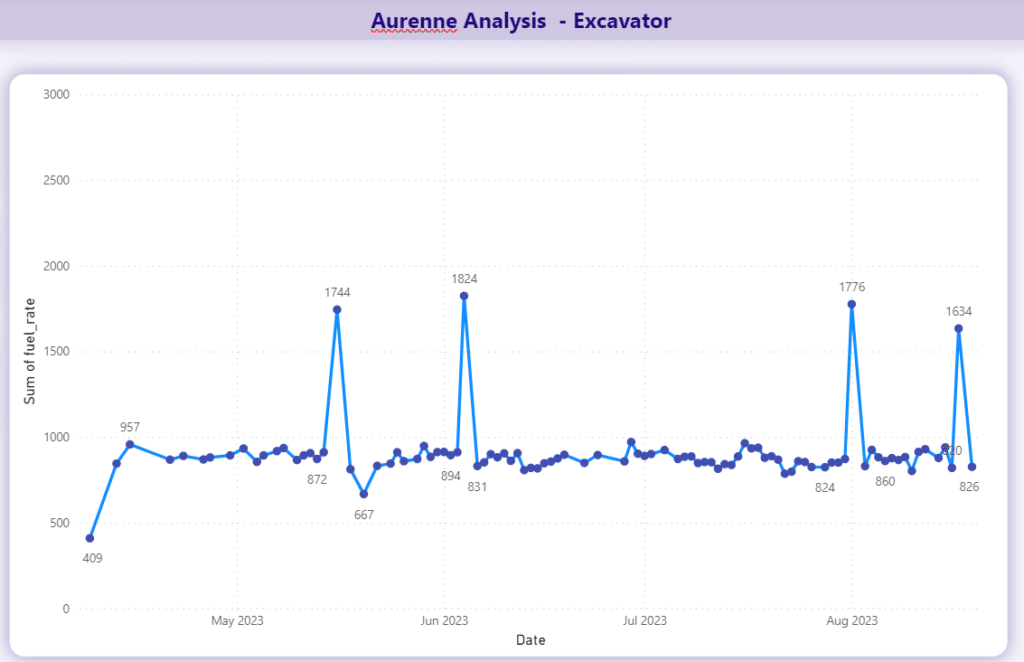

Telemetry data is the next big wave of advancements. Extracting data from diggers provides valuable insights for making precise decisions. Engine hours, fuel data, and other metrics enable efficient machine operation. Trended data aids decision-making for on-site operators and planners, allowing adjustments and feedback for future projects.

Challenges with implementing High Precision Digging

Despite the many benefits of high-precision digging, implementing these techniques comes with its own set of challenges. Workforce training and expertise are crucial for effectively implementing high-precision digging techniques. Skilled operators familiar with advanced machinery and technologies play a pivotal role. Comprehensive training programs for workers or hiring experienced professionals help overcome this challenge.

Productivity and Safety with High-Precision Digging

In today’s environmentally conscious world, safe and sustainable mining methods are imperative. These innovations in high-precision digging not only enhance accuracy but also improve safety while maximizing resource extraction capabilities. As we embrace these advancements, we can expect significant improvements in efficiency and productivity within the mining industry.