On December 6th, the Mine Safety and Health Administration held the final quarterly stakeholder’s call of 2023. The quarterly call is a great opportunity to hear a summary of what has happened in mining health and safety for the previous quarter and what MSHA is working on for the upcoming quarter. Assistant Secretary Chris Williamson explained the significance of having the call on National Miner’s Day, which is the anniversary of the Monongah Mining Disaster in WV. This tragedy claimed the lives of 362 miners, making December 6th, 1907, one of the darkest days in US mining history. The call primarily discussed three topics: The first is the troubling increase in mining fatalities in 2023. The second is MSHA’s focus on improving miners’ training and education and encouraging them to speak up when they see an unsafe act or condition. And finally, a status update on two of the recently proposed rules and what to expect from MSHA for next year.

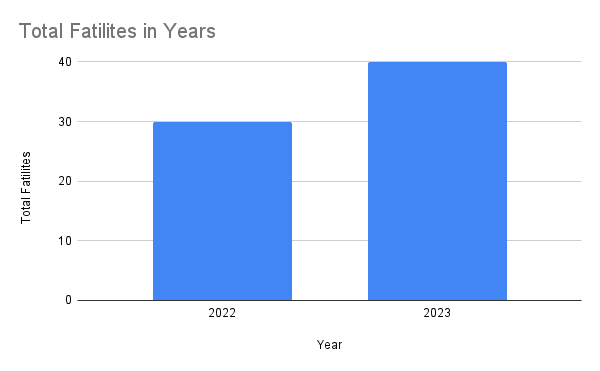

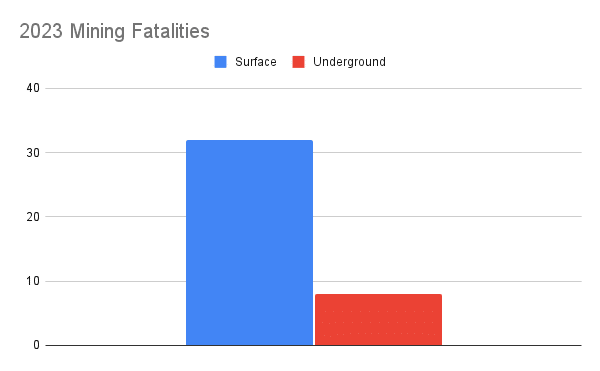

There has been a significant increase in mining fatalities in 2023 with a total of 40 fatalities as of December 30th, which is up from 30 in 2022. 32 of this year’s fatalities have been on surface and 8 have been underground. 17 of the fatalities are classified as Machinery and 10 of the fatalities are classified as Powered Haulage. This means 2023 has had the highest number of powered haulage fatalities since 2006. MSHA has a “Powered Haulage Safety” initiative that has been in place since last year with information available on the msha.gov website. You can find links to training and useful tips on everything haulage related from traffic management to seat belt use to best dumping practices. Powered haulage safety has been and continues to be a major focus of MSHA.

Electrical and Slip and Fall of Person were responsible for 3 fatalities each, making them tied for the third and fourth MSHA fatality causes. And it’s not just mining where these causes lead to fatalities. In 2023, 7 of the 10 most frequently cited serious violations in OSHA construction had to do with working at heights and fall protection. The tragedy is that most of the Electrical and Slip and Fall of Person fatalities are easily preventable. If there is a chance of slipping and falling, ensure that you know how to inspect and use fall protection, and then wear it. If there is a raised working area, always engineer and install controls such as handrails. When it comes to dealing with electricity, ensure that the power is isolated and the person doing the work has the appropriate PPE and training.

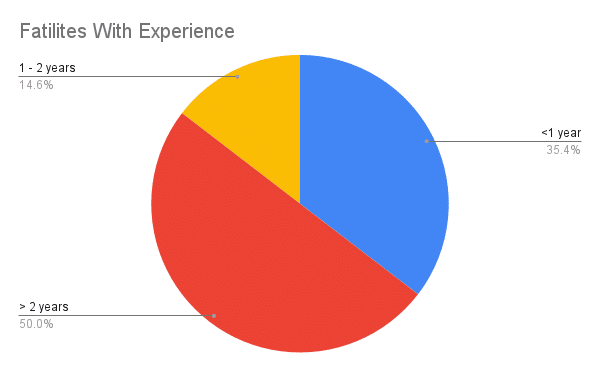

The next topic that MSHA discussed on the call was the “Take Time, Save Lives” initiative. Of the 40 total fatalities this year, 17 happened to miners with less than a year of experience and 7 happened to miners with between one- and two-years’ experience. This means that 24 of the 40 total fatalities happened to miners with less than two years of experience. The “Take Time, Save Lives” initiative is meant to reinforce the importance of training and to ensure that miners understand that under the Federal Mine Safety & Health Act of 1977 a miner “has the right to withdraw themselves if they do not have the required health and safety training”. Miners need to know how to identify risks and hazards both in their work area as well as for the equipment they are operating. It is easy to train the same way year after year, but training needs to be constantly reviewed and updated along with the mine’s training plan.

The third topic of the call concerned a couple of rulemaking updates on proposed rules and improved communication from MSHA. The two proposed rules that were discussed are the Silica rule and the Safety Program for Surface Mobile Equipment. There has been a lot of discussion about the proposed Silica rule which would match MSHA’s action level and Permissible Exposure Limit (PEL) with OSHA’s 2016 rule update. That would mean that MSHA would have an action level of 25 micrograms/cubic meter and a PEL of 50 micrograms/cubic meter. The Silica comment period has ended and MSHA is currently reviewing comments and does not have a time estimate of when or in what form the final rule will go into effect.

The second proposed rule that was mentioned was the Safety Program for Surface Mobile Equipment. This rule preceded the Silica rule by over a year, with the comment period ending in February of 2022. Although it is further along in the rule making process, there still isn’t a time frame of when this rule will go into effect. In summary, this proposed rule would require every operator with more than 5 miners to develop a written Safety Program for all surface mobile equipment. The program would describe the actions that mine operators would take to identify hazards and risks to reduce accidents, injuries and fatalities. This rule would impact everything from operator training to equipment maintenance.

MSHA plans to increase communication with miners and mine operators in 2024 in a couple different ways. They plan to speed up the release of Fatalgrams and will be increasing the number of alerts that are sent out when a troubling trend or hazard is identified. And finally, in addition to the existing quarterly calls, starting in 2024 each district will host their own stakeholder call at least once a year. These calls will focus on what that particular district is seeing from a hazard and compliance perspective and allow mine operators in that area to share their best practices.

Staying informed on statistics and initiatives and being aware of trends is key to maintaining a strong safety program. It is very helpful for MSHA to have these quarterly calls and, in my opinion, having calls at the district level is going to be a meaningful improvement. Communication is key to most things so the more alerts that are released and the more opportunity to hear what is happening in each mine operator’s local area the better off we in industry will be. If anyone would like to listen to the MSHA call in its entirety, the msha.gov website has a recording of each quarter’s call as well as a transcript. Let’s learn from 2023 so that we have a safe and productive 2024.

A Safety Training System commonly used in mines is GroundHogLMS.com

You can also read more about Safety at mines at: https://groundhogapps.com/mining-safety-lms/

About the Author: John Fowler

John Fowler is a Certified Safety Professional and a Certified Mine Safety Professional who has worked on projects ranging from offshore oil/gas platforms in Alaska to both surface and underground mines in the western US. You can contact John at: john.m.fowler@gmail.com.