California, USA — GroundHog, a trailblazer in mining technology, proudly announces the launch of its state-of-the-art high-precision solution, setting a new standard for precise drilling in mining operations.

Holistic Integration for Streamlined Drilling:

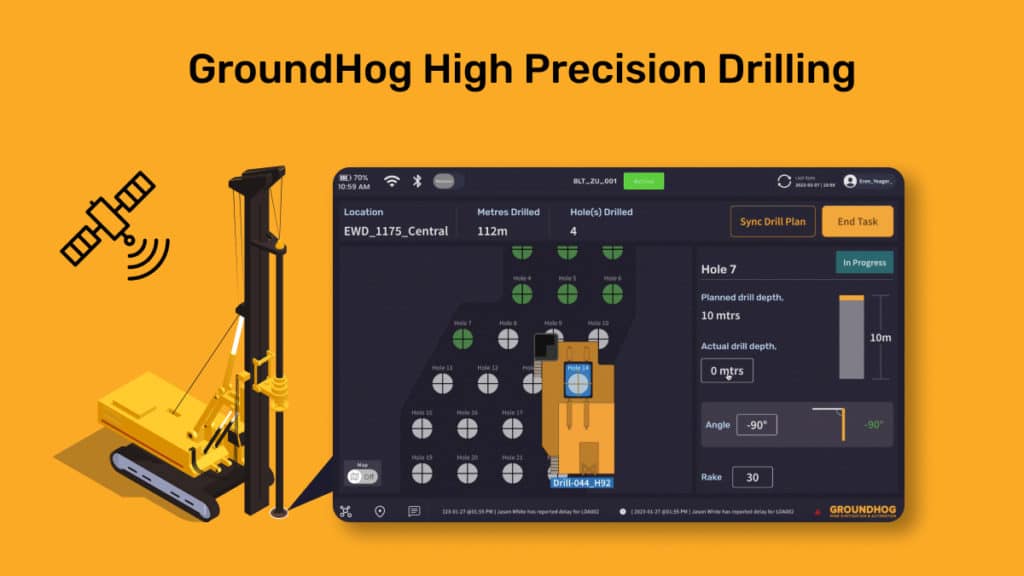

GroundHog takes a significant leap by acting as an integrator, bringing together a complete solution to streamline drilling operations. The integration includes strategically positioned base stations, RTK receivers with 2cm accuracy, and dual antennas—ensuring optimal signal coverage. The GroundHog Operator app further enhances this cohesive approach, offering mining operators a unified solution for maximum efficiency.

Innovative Features Redefining Efficiency:

The distinctive feature of this solution is the integration of GroundHog visualization, tracking drill status, hole details, consumables, and additional information within the operator app. This powerful combination enables precise data collection, offering operators immediate insights into drilling processes. It promotes adherence to drill plans, addresses the common challenge of data quality in drill operations and transitions from traditional pen-and-paper methods to electronic data capture for improved efficiency.

“Conventional drilling without precision techniques poses multiple negative impacts, with drill operators spending substantial time on drill placement. Deviations in drill holes lead to improper burden, spacing, angle and depth of drill holes which in turn lead to safety and productivity issues. High-precision drilling minimizes these impacts, ensuring better adherence to plans and enhancing overall operational efficiency.”, says Amitava Dutta, Director – Product Operations, GroundHog

The standout benefit of High Precision technology lies in its ability to get accurate equipment navigation and control even in challenging terrains or complex ore bodies. Highly accurate position information allows to guide the equipment, laying the groundwork for autonomy eventually.

Addressing Data Quality Challenges in QA/QC:

Data quality issues pose significant challenges in QA/QC in drill and blast operations. Any deviation from the designed parameters can impact final blasting results, affecting successive processes such as loading, hauling, and crushing. Precise drilling reduces these chances of deviation, enabling improved drill productivity, optimal blast fragment size, reduced toe generation, improved excavator and truck productivity, precise sampling, and enhanced quality control of ore and crusher productivity.

GroundHog’s high-precision solution is a testament to its commitment to innovation, efficiency, and addressing industry challenges. The integration of advanced technologies positions GroundHog as a leader in advancing mining practices.

About GroundHog

As a leader in Mine Digitization and Automation, GroundHog empowers mines to increase profitability by enhancing production rates safely and efficiently. The platform streamlines workflows across mine planning, operations, maintenance, geology, and safety teams, serving as a single source of truth. Used by some of the world’s largest mining companies and contractors in both open-pit and underground operations, GroundHog’s mission is to digitize every mine to increase profitability without sacrificing safety.

Developed and tested by industry experts worldwide, GroundHog’s products and services simplify complex workflows, specializing in short-interval control, fleet management, and environmental, health, and safety tools.

For more information, visit www.groundhogapps.com.

Media Contact: getStuffDone@groundhogapps.com