Short Interval Control Training is key to transition a mine from traditional paper-based Short Interval Control (SIC) methods to digital systems in mining operations is a strategic move towards improving efficiency, safety, and decision-making. This process involves several key steps and training initiatives to ensure a smooth shift:

Initial Assessment and Strategy Development

The transition begins with a thorough assessment of the current paper-based SIC processes to understand their strengths and limitations. This assessment helps in designing a tailored digital SIC strategy that aligns with the specific needs and goals of the mining operation. The strategy outlines the objectives, the digital tools and platforms to be adopted, and the timeline for the transition.

Selection of Digital Short Interval Control Tools

Selecting the right digital tools is crucial for the successful adoption of digital SIC methods. The chosen tools should be user-friendly, compatible with existing systems, and capable of providing real-time data and analytics to support quick decision-making. This selection process often involves consultations with technology providers and possibly customizing solutions to fit the mining operation’s specific requirements.

Comprehensive Short Interval Control Training Programs

Training is a critical component of the transition process. It is designed to equip miners and supervisors with the necessary skills and knowledge to effectively use the new digital SIC systems. The training typically covers:

- Basic Digital Literacy: For individuals who may not be familiar with digital technologies, training starts with the basics of operating digital devices and navigating software interfaces.

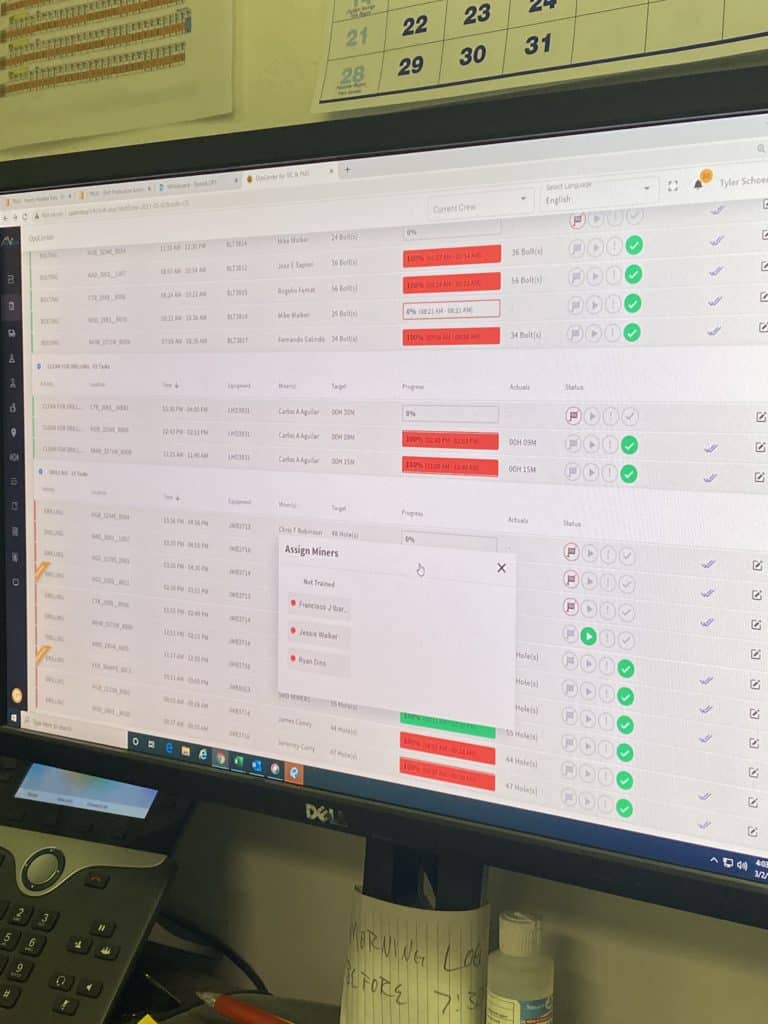

- Operational Training: Detailed instructions on how to use the specific digital SIC tools, including data entry, monitoring dashboards, analyzing data, and generating reports.

- Best Practices and Protocols: Training on the best practices for using digital SIC systems, including data accuracy, privacy, and security protocols.

- Troubleshooting: Basic troubleshooting techniques for common issues that users might encounter with the digital tools.

Training can be delivered through various formats, such as in-person workshops, online tutorials, and on-the-job training sessions, ensuring flexibility and accessibility for all employees.

Short Interval Control Pilot Phase and Iterative Feedback on Training

Before full-scale implementation, we at GroundHog strongly recommend a pilot phase. This pilot is often conducted in a specific section of the mining operation. This allows for real-world testing of the digital SIC system and the training effectiveness. Feedback is gathered from participants to identify any challenges, usability issues, or additional training needs. This feedback is then used to refine the digital tools and training programs.

Ongoing Support and Continuous Learning

After the initial rollout, ongoing support is provided to address any emerging questions or challenges. This includes a dedicated helpdesk, online resources, and regular refresher training sessions. Continuous learning is encouraged through advanced training modules that cover more sophisticated features of the digital SIC systems and data analysis techniques.

Integration into Daily Operations

For the digital SIC methods to be fully adopted, they need to be seamlessly integrated into the miners’ and supervisors’ daily workflows. Supervisors play a crucial role in this integration by leading by example, using the digital SIC tools in their daily management activities, and encouraging their teams to do the same.

The transition from paper-based to digital Short Interval Control methods is a significant change that requires careful planning, tailored training, and ongoing support. By investing in the right tools and training, mining companies can ensure that their workforce is equipped to take full advantage of the benefits that digital SIC methods offer.

To learn more about GroundHog’s Short Interval Control system, click here

To learn more about GroundHog Academy to train your operators on Short Interval Control, click here

To learn more about Short Interval Control, a factory process, please click here

What specific digital tools and software are most effective for implementing Short Interval Control in mining operations?

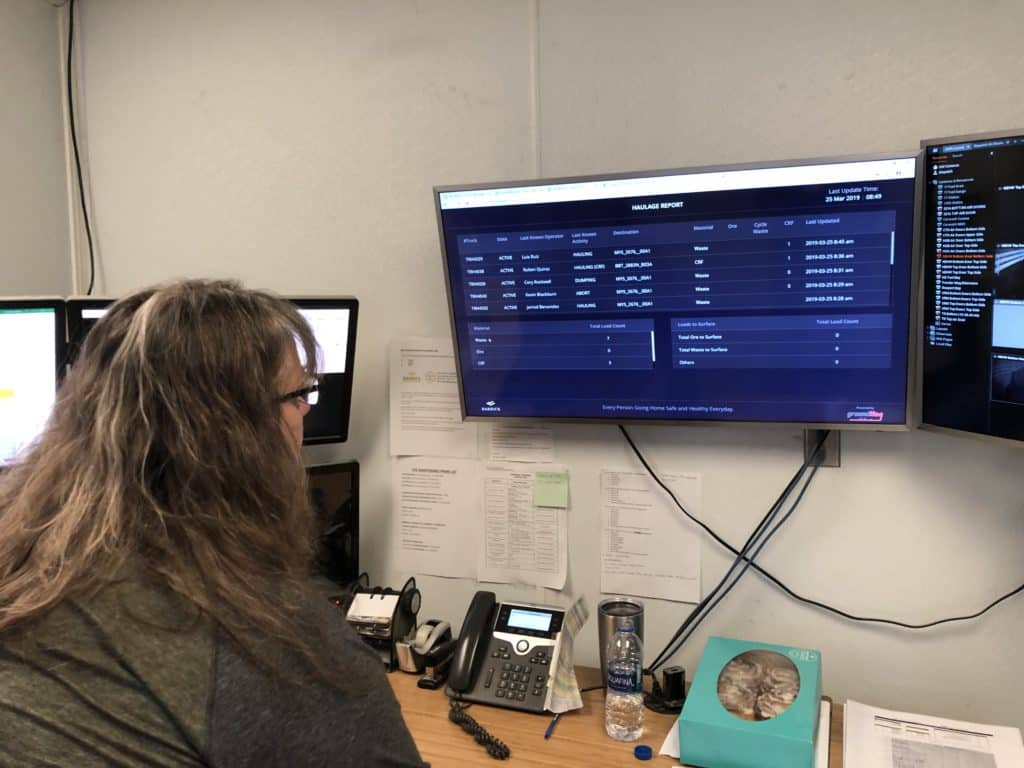

In the realm of mining operations, the transition to digital Short Interval Control (SIC) methods has been marked by the adoption of various digital tools and software, each designed to enhance real-time decision-making and operational efficiency. Among the most effective digital solutions are integrated mine planning and operation platforms that offer a comprehensive suite of functionalities, from data collection and analysis to visualization and reporting. These platforms often include features like real-time monitoring of equipment and personnel, predictive analytics for maintenance and workflow optimization, and customizable dashboards that provide a clear overview of operational metrics.

Additionally, mobile applications have become instrumental in bridging the gap between field personnel and central control operations. These apps facilitate on-the-go data entry and access, enabling immediate updates and adjustments to work plans based on current conditions. Collaboration tools are also integral, allowing teams to communicate and coordinate effectively, irrespective of their physical locations.

Another critical component is the use of IoT devices and sensors, which collect vast amounts of data from various points within the mining operation. When integrated with SIC software, this data can be analyzed in real-time, providing insights that drive more informed decision-making and rapid response to operational changes.

The effectiveness of these digital tools and software in implementing SIC in mining operations is further enhanced by their ability to integrate with existing systems and workflows, ensuring a seamless transition from traditional methods and enabling a more agile, responsive operational environment.

How do companies measure the success and effectiveness of the transition to digital SIC systems?

Companies measure the success and effectiveness of the transition to digital Short Interval Control (SIC) systems through a combination of quantitative metrics and qualitative assessments. The primary aim is to evaluate improvements in operational efficiency, decision-making speed, and overall productivity. Key performance indicators (KPIs) play a crucial role in this evaluation process.

One of the main quantitative metrics is the improvement in production efficiency, which can be measured by comparing output rates before and after the implementation of digital SIC systems. Companies also look at the reduction in downtime, which is a direct indicator of enhanced operational efficiency. This is often quantified by tracking the time saved due to more efficient troubleshooting and maintenance processes enabled by real-time data monitoring.

Another significant metric is the improvement in safety records. Digital SIC systems often lead to safer working conditions by providing better monitoring and faster response to potential safety issues. The number of safety incidents before and after implementation can provide a clear measure of success in this area.

Cost reduction is also a critical measure, with companies evaluating the savings achieved through more efficient resource allocation, reduced waste, and optimized energy consumption. These cost savings can be directly attributed to the more precise control and planning enabled by digital SIC systems.

On the qualitative side, companies assess the level of employee engagement and satisfaction with the new systems. This includes evaluating how well employees have adapted to using digital tools and whether there has been an improvement in collaboration and communication within teams.

Feedback from employees about the usability and effectiveness of the digital tools provides valuable insights into how well the digital SIC systems are supporting operational goals. Additionally, the degree of integration of digital systems into daily operations and decision-making processes is evaluated to understand the extent to which digital SIC has become embedded in the organizational culture.

Together, these quantitative and qualitative assessments provide a comprehensive picture of the success and effectiveness of the transition to digital SIC systems, highlighting areas of improvement and identifying opportunities for further optimization.