In this article, we will go over the Technology used to achieve high precision drilling. In the dynamic landscape of contemporary mining operations, the infusion of cutting-edge technology has revolutionized the collaboration between mine engineers, dispatchers, and drill operators. Here’s an insightful overview of the streamlined process:

Drill Plan Upload:

Mine engineers or dispatchers initiate the process by seamlessly uploading the high precision drilling plan to GroundHog Operations Center. Information includes Bench ID, Hole Numbers, precise latitude and longitudes, and a drill depth to ensure proper blasts. This plan is securely stored in the cloud, ensuring accessibility while prioritizing data security. These drill plans get directly sync’d to the Blast Hole Drills.

Real-Time Accessibility:

The uploaded high precision drill plan becomes instantly available in real-time on the drill operator’s application. This real-time synchronization facilitates efficient communication and seamless execution of the drilling plan.

RTK Receivers and Dual Antennas:

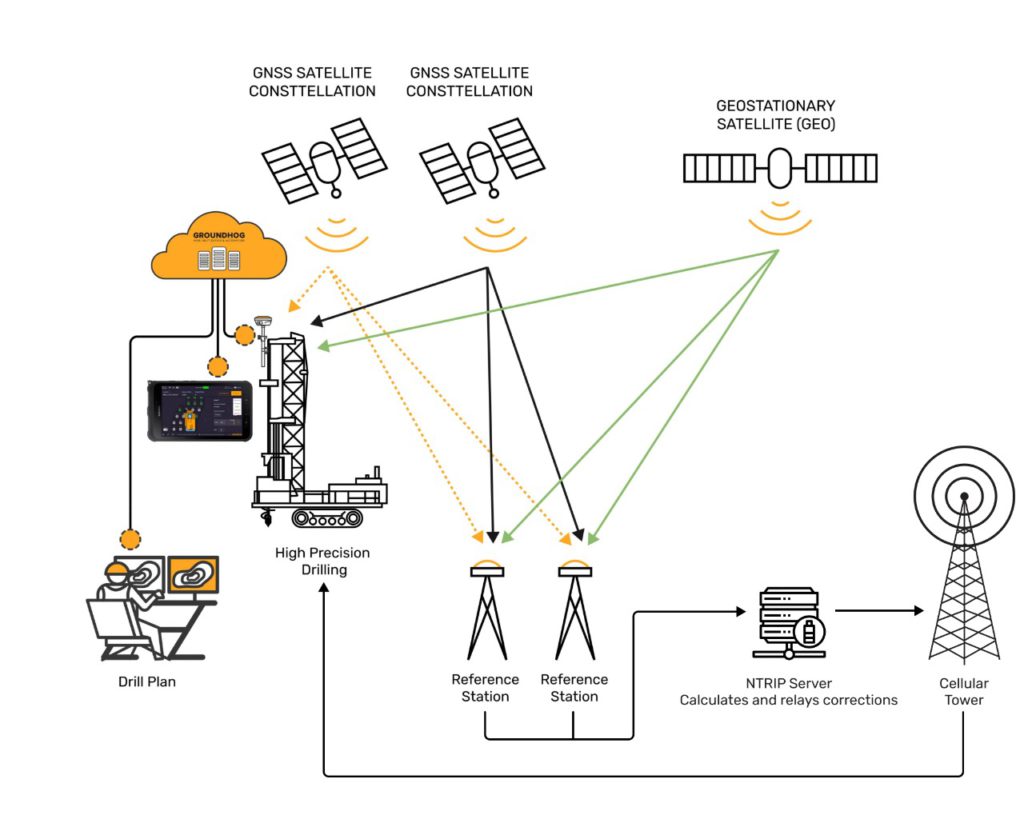

The drill is outfitted with Real-Time Kinematic (RTK) receivers and dual antennas, strategically placed at the front and rear. This configuration significantly amplifies the precision of location data for meticulous drilling operations, with receivers consistently receiving satellite signals from various constellations.

Single Base RTK System:

In a single-base RTK system, a specific control point on-site is identified, and a base station is installed, often elevated on concrete pillars. The single base station continually receives signals from satellite constellations and simultaneously transmits correction data directly to the drill operator’s receiver, minimizing latency within a 15-20km range.

Network RTK System:

Alternatively, a Network RTK system relies on an existing network of reference stations. These base stations consistently receive satellite signals and transmit correction data to an NTRIP caster via the Internet. The caster in turn relays this data to a cellular tower which in turn transmits the data to the drill operator’s receiver via IP or cellular communication.

GroundHog Operator App for High Precision Drilling:

With location information at hand, the operator app serves as a guiding tool, assisting operators in executing drilling plans accurately. The app actively tracks any deviations from the plan, providing real-time feedback to enhance operational precision. This seamless integration of technology optimizes efficiency and accuracy in mining operations.

GroundHog OpsCenter to manage High Precision Drilling Plans:

The data generated by the operator app is seamlessly transmitted to the GroundHog OpsCenter via the cloud. This allows dispatchers and mine engineers to receive realtime updates on performance against the plan, facilitating informed decision-making and optimizing overall operational efficiency. GroundHog OpsCenter acts as a centralized hub for monitoring and managing drilling operations, enhancing coordination and collaboration across the entire mining workflow.

Some of the companies that provide the RTK based High Precision GPS units include Trimble, Topcon, EMLID and Eos (their Arrow line). GroundHog uses Trimble and Eos devices, based on device availability in a particular region. The result is a GPS system capable of providing centimeter-level or even millimeter-level accuracy, making it ideal for High Precision Drilling and High Precision Digging applications.

*This blog is an excerpt from our e-Book. For more on this topic, download our e-Book.

The Author of this e-Book is Mr. Amitava Dutta. Mr. Dutta is a seasoned Mining Engineer with a. demonstrated history of working in Mining Operations, Mine Planning, Technical Services,

Mining Consultancy, and Mine Digitization Globally. As Director of Product Operations at GroundHog, he. drives Product Operations, Digital Transformation, and Customer Success and supports Product

Development and Business Development Strategy.

Mr. Dutta has deep expertise in the implementation of Mine Digitization, Mine Automation, and Process Efficiency Improvement for highly mechanized mines. He has demonstrated capabilities in Mine Digitization, Mine Planning Software, Fleet Management Solutions, Mining Simulation, Equipment Asset Management, Asset optimization, and many Business Excellence Tools. Successfully implemented many cost-saving and energy-saving projects for mining process efficiency improvement.