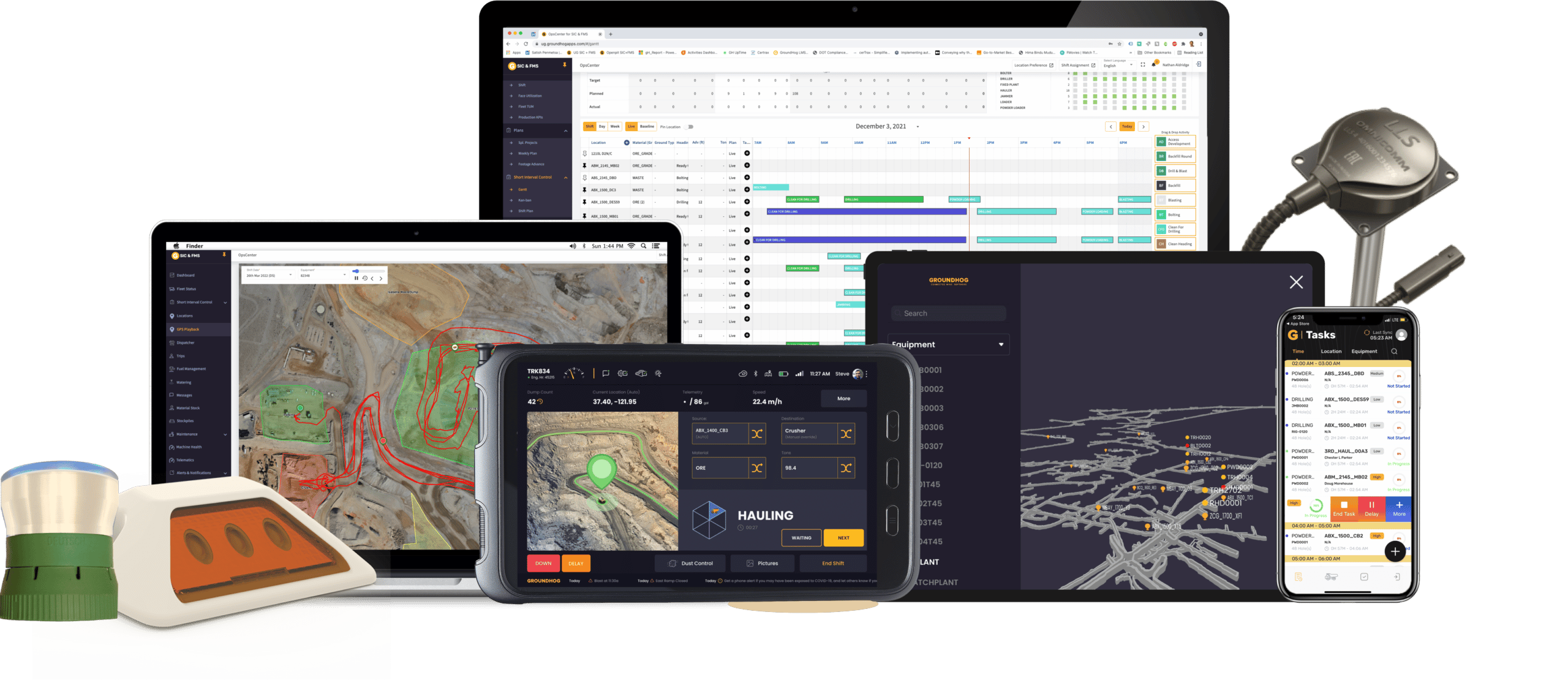

The Mine Digitization and Automation Platform

Unified Platform for Operations, Maintenance, Quality Control, and Safety Management

The world’s largest mines use GroundHog to mine more tons, faster and SAFER

The world’s Largest Mines

Digitize and Automate with GroundHog

Built to Get Stuff Done!

Groundhog gave us the real-time visibility we needed to meet our daily, weekly, and monthly targets.

It took our shift-bosses a couple of weeks to change their line-out process to Groundhog. The supervisor, mine manager and operator apps ensure that everybody is on the same page. The crew now executes shift priorities as one single unit.

Awesome Platform and Amazing Support!Matt Swanson, Continuous Improvement Manager, Cementation Americas

Purpose built for solving Mine Digitization and Automation Use Cases

Short Interval

Control For Mining

Used by production planners and shift bosses to get 40% more tonnes to surface every shift by planning and tracking production and support mining activities.

Fleet

Management For Mining

Used by dispatch and maintenance to get accurate real time fleet production, performance and health data from all equipment on the mine site.

Data Mules on

Peer-to-Peer

Networks For Mining Companies

Used by miners and supervisors to get production and machine health data from equipment and personnel working in remote locations underground.

Environmental,

Health and

Safety For Mining Companies

Used by Safety Managers to

increase regulatory compliance and reduce incidents and hazards using better safety data logging and analytics tools.

IIoT and

Telematics

Used by mine ops and safety

teams to integrate with sensors and actuators to automate production and safety operations in mines.

Safety

Training LMS

Used by safety trainers and

supervisors to ensure every miner

is trained to perform their work

safely and efectively

Remote

Operations

Centers

Used by mine operators to monitor mining activity and asset performance and make data driven decisions in real time in consolidated remote operations centers.

Real Time

Location

Services

Used by dispatch and safety to increase situational awareness by track all personnel and equipment in real time

Mine Digitization and Automation Technology Experts

Greedy

Algorithms

Used by production planners and shift bosses to get 40% more tonnes to surface every shift.

Machine

Learning/ AI

Used by production planners and shift bosses to get 40% more tonnes to surface every shift.

Data

Lakes

Used by production planners and shift bosses to get 40% more tonnes to surface every shift.

Digital

Twins

Used by production planners and shift bosses to get 40% more tonnes to surface every shift.

Companies use GroundHog’s

Mine Digitization Software to

mine more tons, faster, cheaper

and safer.

Why Groundhog is the #1

mine digitization software.

See how our customers mine 40% more tons every shift

- Have 360º visibility in real time, anywhere, anytime

- Get 40% more tons to surface, every shift

- Increase Face Utilization and Equipment utilization

- Enhance safety and situational awareness

- Automate Trip Counts, Track Tonnes and Equipment Performance

- Streamline grade and material reconciliation

About GroundHog

easy to use connected miner software.