It’s been said that you can’t master what you don’t measure, and this couldn’t be more true for operations within the mining industry. While mining companies’ work around the clock to meet production goals, simultaneously maintaining the highest safety standards, are they measuring what matters most to help them meet the targets that they’ve set? What are their operational KPI based on?

We sat down with some of our customers to work through what they are measuring, why they have prioritized these, and how it matters most to their mining operation.

The metrics and operational KPIs that we identified as being top priorities to our mining customers fall into three categories. Here are the top metrics that can be best measured and managed using the right operational technology on-site:

Operational KPI for Machine assets: Operational metrics that stand to matter most to mining companies often relate to their assets, specifically their equipment, since purchasing, operating, and maintaining fixed and mobile assets is often mining’s largest expenses — often up to 50% of overall operating costs. Some of the most common equipment-related metrics and operational KPIs that our customers monitor include:

- Average cost to repair

- Mean time to repair

- Average equipment downtime

- Total cost of ownership

Operational KPI for Human assets: Safety is historically the highest priority for the mining industry, from the beginning of mining. Due to harsh and rugged environments, often many thousands of feet below the surface, and huge equipment moving around, it is filled with danger. Every mine operator cares about the safety and health of their fellow workers, and strict compliance standards and regulations are in place to protect human lives. The most commonly monitored operational KPIs that we found include:

- Injury free hours

- MSHA/OSHA recordable injuries

- Worker compensation costs

- Safety training and compliance rates

Operational KPIs for ESG and Sustainability: As the mining industry makes the full shift to support environmental, social and governance standards, mining operations have begun tracking “green indicators”, with a heavy emphasis on the environmental impact. Green KPIs include:

- Carbon footprint (supply chain)

- Emissions and fuel monitoring

- Energy consumption

- Product recycling rate

- Water footprint

- Ecosystem impact

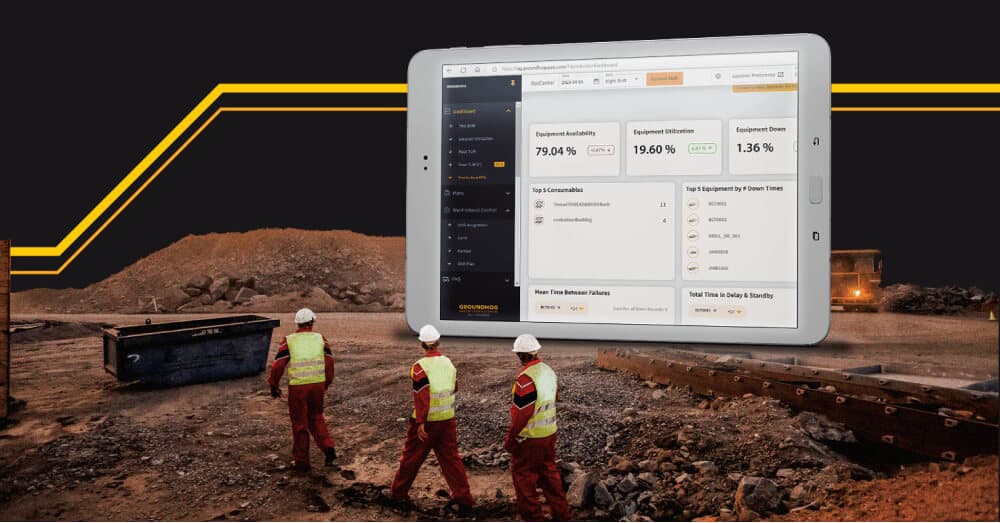

Many mining companies have turned to GroundHog’s technologies to deliver the operational advantages that they need in order to not only monitor, but optimize the way they are operating in real-time. All the KPIs that you need to measure can be streamlined and strategized using the GrondHog suite of products, including:

Short Interval Control to help you move more tons

Fleet management OP to continuously optimize haul cycles and routing

Fleet Management Underground to enhance safety and efficiency underground

Proximity detection/collision alert to increase situational awareness and reduce risks

Telematics for informed decisions

Safety training for certification, compliance and regulatory success

Fuel monitoring to save 20% or more consumables

Information is power, and making data informed choices will continue to leverage best practices to meet operational KPIs.